Circuit Breaker Trip Structure

A circuit breaker and tripping technology, which is applied in the field of circuit breaker tripping structure, can solve the problems of inability to guarantee forced closing, inability to ensure safety due to arrears and electricity theft, and achieve the effect of ensuring safety and preventing arrears and electricity theft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

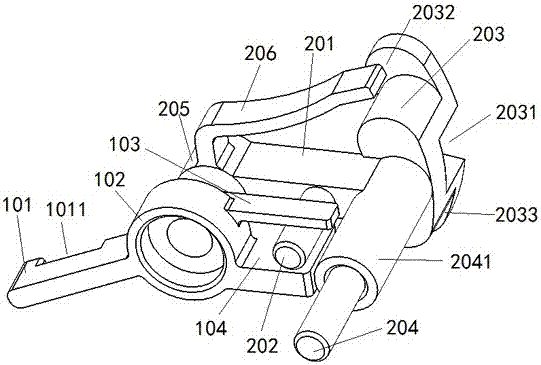

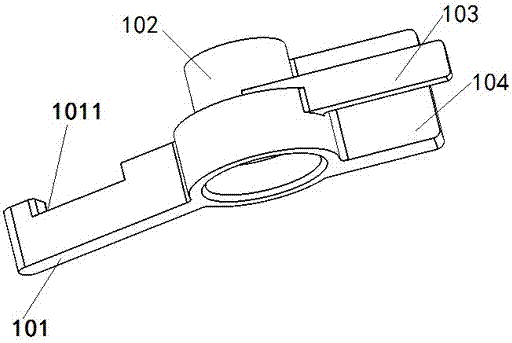

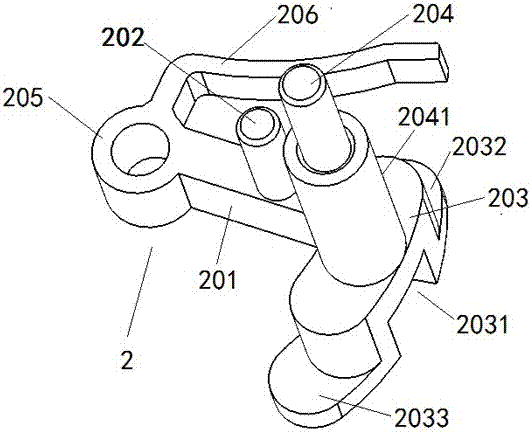

[0032] Such as Figure 1~6 As shown, the tripping structure of the circuit breaker is installed in the housing 3 of the electric control operator; the tripping structure of the circuit breaker includes a tripping driving part 1 and a tripping rotary part 2; the tripping driving part 1 and the tripping rotary part 2 have shaft holes and have the same axis center, and the tripping driving part 1 and the tripping rotary part 2 are movably connected through a fixed shaft; One side of the sleeve 102 extends laterally with a drive rod 101; the drive rod 101 has a second groove 1011, the second groove 1011 is square, and the trip driver 1 is provided with a first shaft sleeve 102 extending in the axial direction, and the trip The other side of the driving member 1 and the first sleeve 102 jointly extend in the transverse direction with a first clamping piece 103 and a second clamping piece 104; there is a rotation between the first clamping piece 103 and the second clamping piece 104...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com