Air-permeable velvet shell fabric capable of emitting fluorescent light

A breathable, velvet technology, applied in clothing, protective clothing, special outerwear, etc., can solve the problems of fabrics not being able to emit light, and achieve the effects of simple and light structure, convenient and flexible use, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

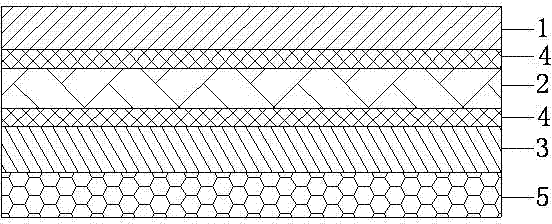

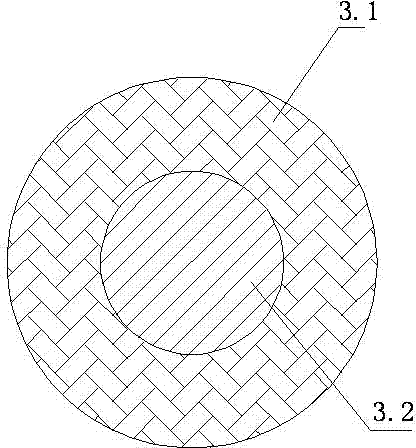

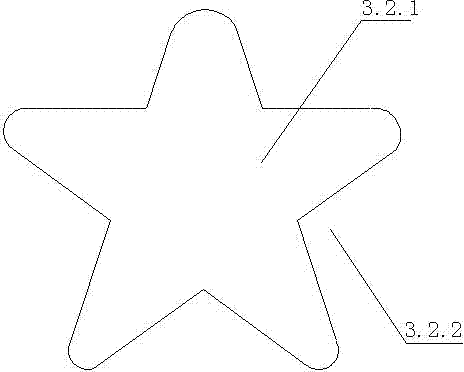

[0014] see Figure 1 to Figure 3 , the present invention relates to a kind of fluorescent light-emitting air-permeable velvet fabric, it comprises velvet cloth 1, and the bottom of this velvet cloth 1 is provided with sponge layer 2, and the bottom of sponge layer 2 is provided with air-permeable layer 3, and this air-permeable layer 3 is polyester fiber 3.1 and polyamide fiber 3.2 are woven by blending, wherein polyester fiber 3.1 is the cortex, polyamide fiber 3.2 is the core layer, the polyamide fiber 3.2 has hydrophilicity, and the polyamide fiber section 3.2.1 of the polyamide fiber 3.2 is It is in the shape of a five-pointed star, and a groove 3.2.2 is formed between two adjacent corners of the five-pointed star. Sweat is discharged from the groove 3.2.2 to the surface of the fabric, thereby being volatilized, thereby achieving the purpose of ventilating and sweating. A base layer 5 is compounded under the layer 3, and the glue layer 4 is used for bonding between the vel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com