Backlash-free spindle nut

A technology without gaps and nuts, applied in belts/chains/gears, mechanical equipment, transmissions, etc., can solve problems such as large build lengths, and achieve simple manufacturing processes, simple cost-effectiveness, and extensive design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

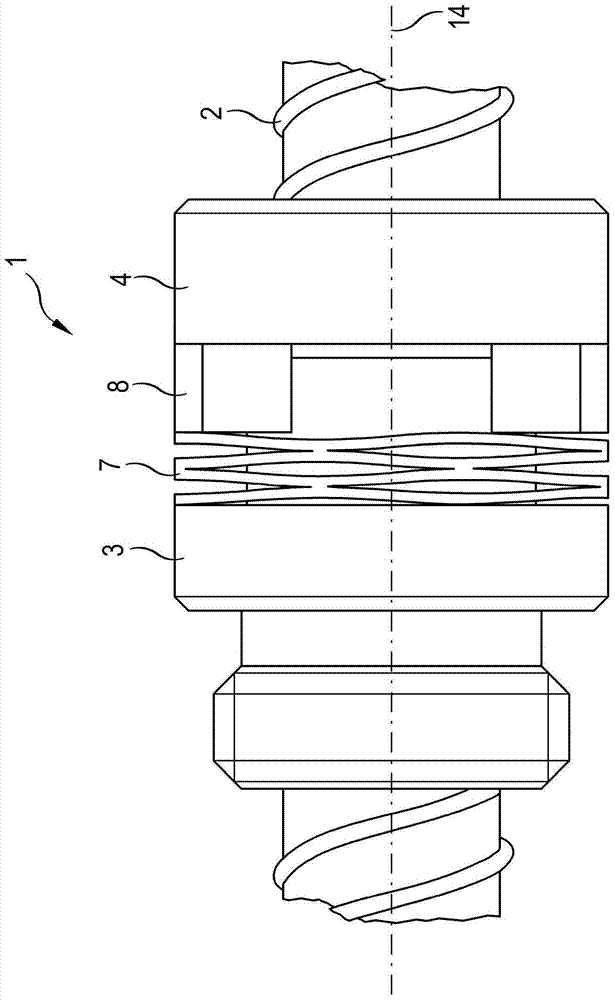

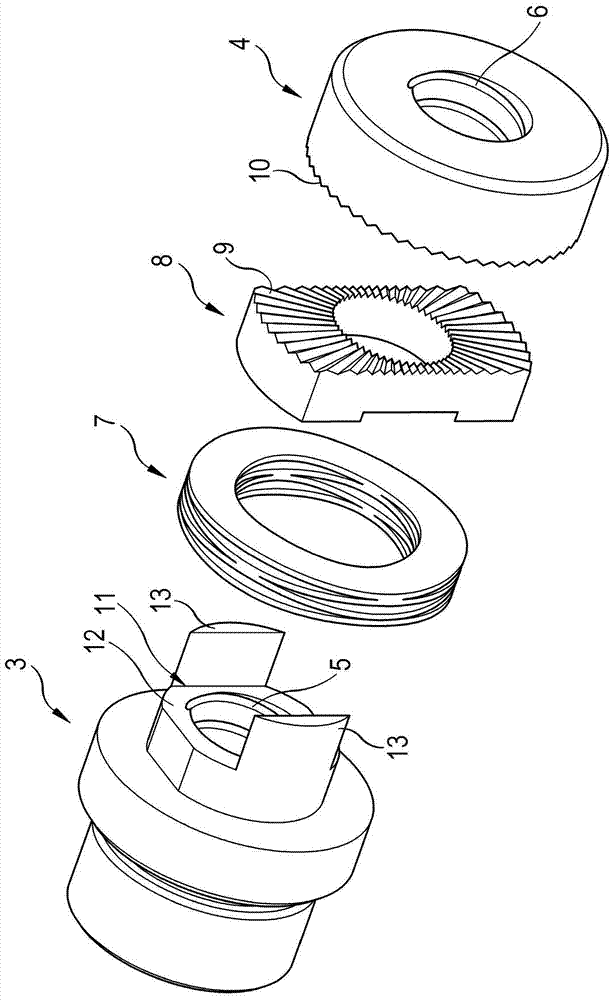

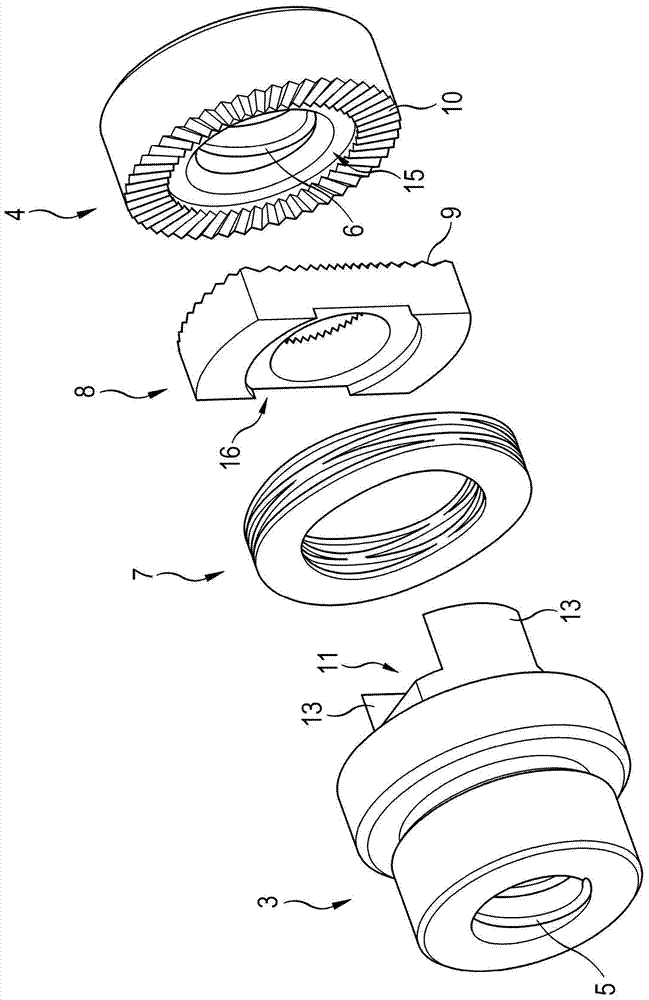

[0035] figure 1 An example of a spindle nut 1 screwed on a spindle 2 according to the invention is shown. The spindle nut comprises a first nut part 3 and a second nut part 4 each having a base unit which is substantially formed rotationally symmetrically with respect to the axis 14 of the spindle nut. Between the first nut part 3 and the second nut part 4 there is an intermediate part 8 which is pressed onto the second nut part 4 by means of a multi-wave spring washer 7 which on the one hand is aligned with the first nut The part 3 and on the other hand are aligned with the intermediate part 8 .

[0036] The structure of the spindle nut according to the present invention is achieved by figure 2 and an exploded view of 3 is shown in more detail. The first nut part 3 comprises a substantially hollow cylindrical protrusion 12 having an outer diameter smaller than the outer diameter of the first nut part itself. The multi-wave spring washer 7 is fastened on the protrusion 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com