A kind of preparation method of graphene film for supercapacitor

A graphene film and supercapacitor technology, applied in the manufacture of hybrid/electric double layer capacitors, etc., can solve problems such as graphene film electrode materials, unfavorable large-scale production, etc., to achieve superior supercapacitor performance and promote charge transfer. , the effect of good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

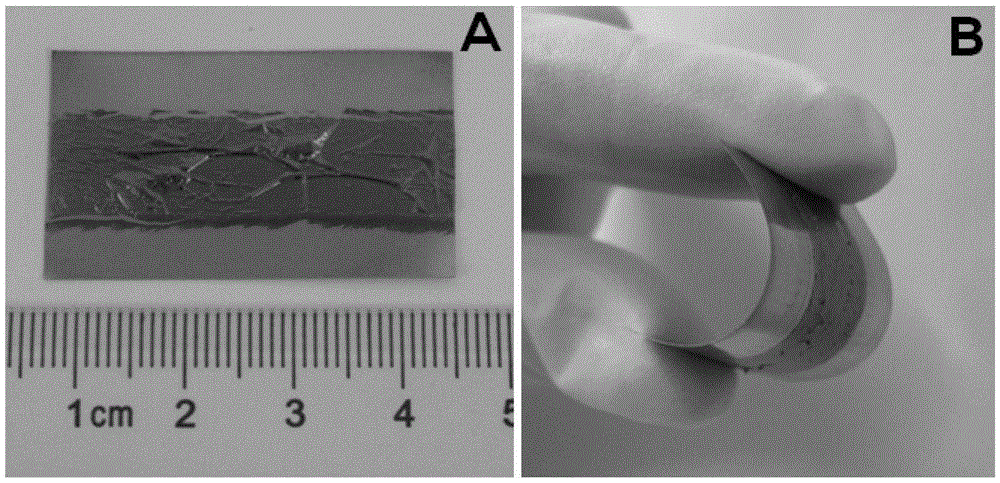

[0026] The graphite oxide prepared by the Hummer method was washed twice with deionized water without drying, and then mixed with deionized water to form a suspension, ultrasonicated for 3h, centrifuged at 3500r / min for 20min to remove the precipitate, and then the obtained graphite oxide dispersion was rotary evaporated at 40°C Until the formation of graphite oxide sol. The prepared graphite oxide sol was scraped on the surface of the titanium foil, 120μL of hydrazine hydrate was added dropwise to the inner tank of the reactor, and the scraped film was placed in the reactor, placed in an oven at 90°C for 15 hours, and washed with deionized water 3 times.

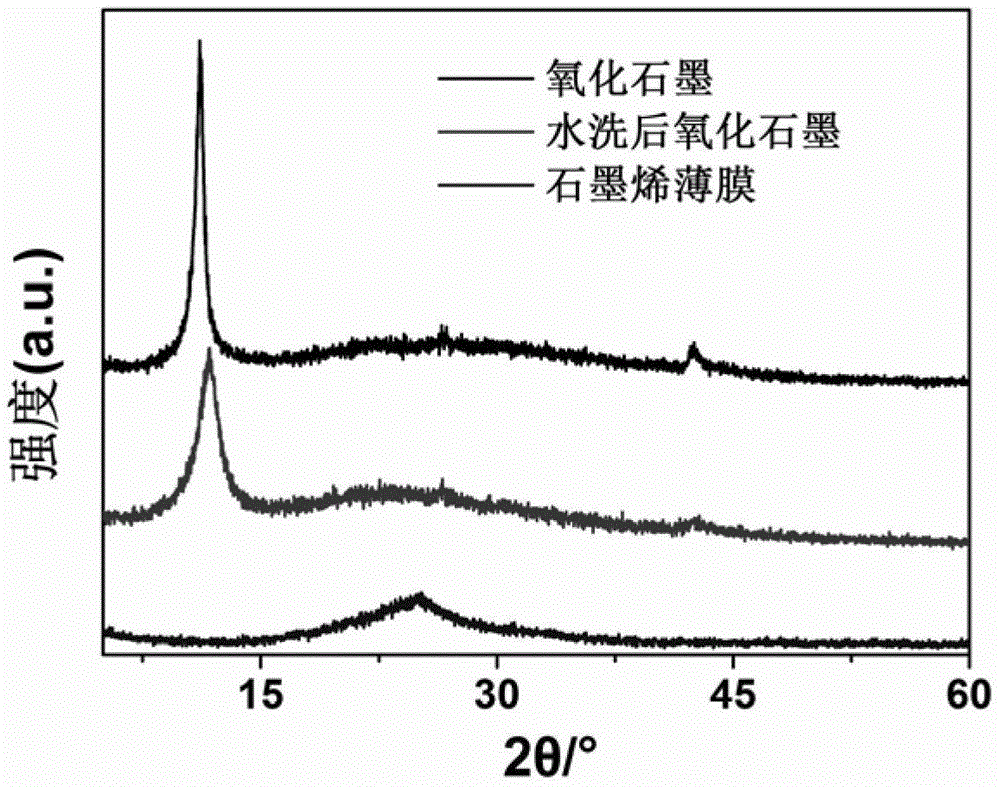

[0027] figure 1 In order to compare the X-ray diffraction patterns of graphite oxide, graphite oxide after washing, and graphene film in the process, the graphite oxide and graphite oxide after washing in the figure both show strong diffraction peaks at 2θ≈11°, but the after washing The peak intensity of graphite oxide decre...

Embodiment 2

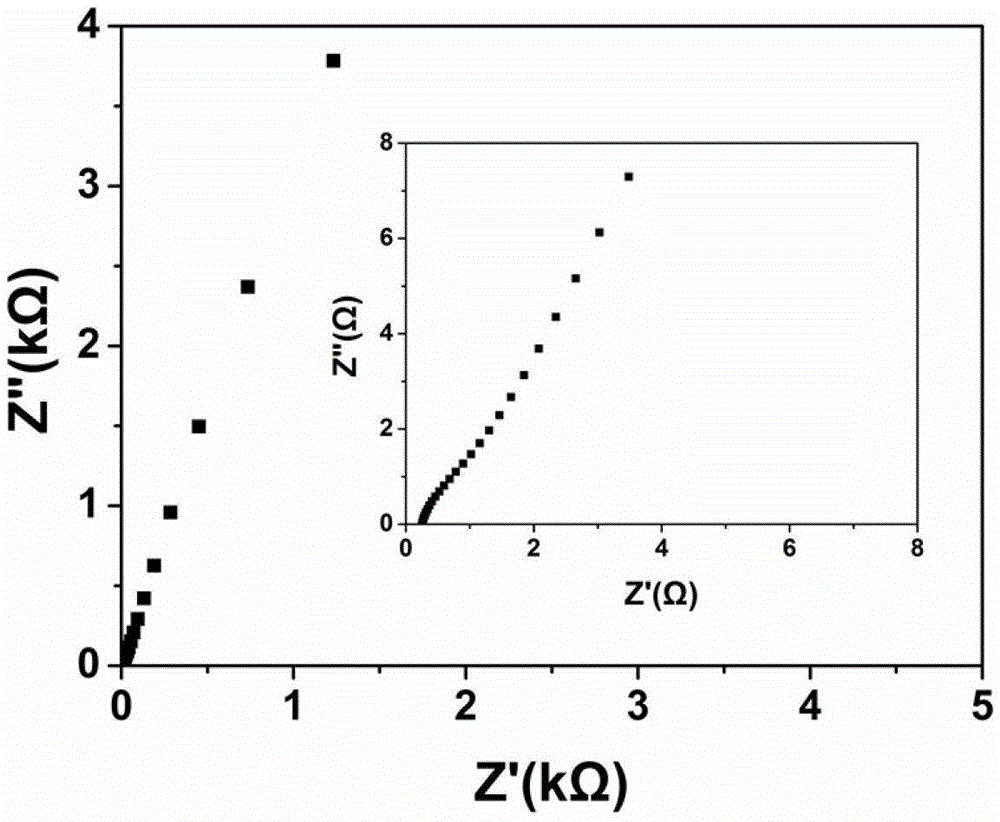

[0033] The graphite oxide prepared by the Hummer method was washed with deionized water for 6 times without drying, and then mixed with deionized water to form a suspension, ultrasonicated for 1h, and centrifuged at 2000r / min for 40min to remove the precipitate, and then the obtained graphite oxide dispersion was rotary evaporated at 45°C Until the formation of graphite oxide sol. The prepared graphite oxide sol was scraped on the surface of the titanium foil, 40μL of hydrazine hydrate was added dropwise to the inner tank of the reactor, and the scraped film was placed in the reactor, placed in an oven at 120°C for 4 hours, and washed with deionized water 8 times. X-ray diffraction analysis showed that for the preparation of graphene films, impedance analysis showed that the contact resistance and charge transfer resistance were low, the cyclic voltammetry curve analysis had higher specific capacitance, energy density and power density, and the constant current charge and disch...

Embodiment 3

[0035] The graphite oxide prepared by the Hummer method was not dried and washed with deionized water for 4 times, then mixed with deionized water to form a suspension, ultrasonicated for 2h, 3000r / min for 30min to remove the precipitate, and then the obtained graphite oxide dispersion was rotary evaporated at 45°C Until the formation of graphite oxide sol. The prepared graphite oxide sol was scraped on the surface of the titanium foil, 80μL of hydrazine hydrate was added dropwise to the inner tank of the reactor, and the scraped film was placed in the reactor, placed in an oven at 100°C for 12 hours, and washed with deionized water 5 times. X-ray diffraction analysis showed that for the preparation of graphene films, impedance analysis showed that the contact resistance and charge transfer resistance were low, the cyclic voltammetry curve analysis had higher specific capacitance, energy density and power density, and the constant current charge and discharge analysis had bette...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com