A rapid separation and detection method for whey protein components in dairy products

A whey protein and detection method technology, which is applied in the direction of material separation, measuring devices, and analysis materials, can solve the problems of inability to separate and measure, and achieve the effects of rapid detection, good reproducibility, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

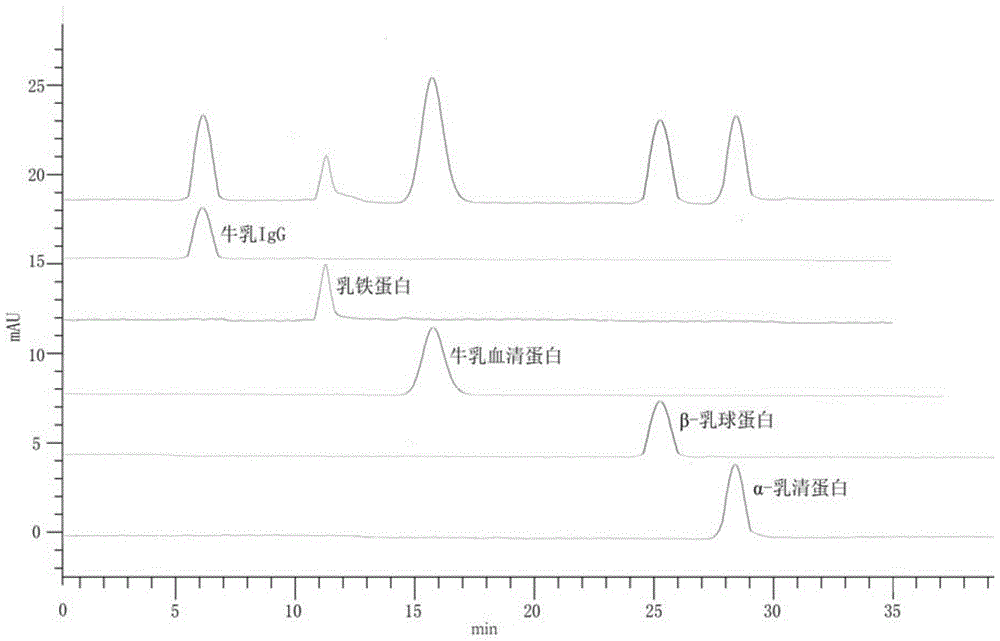

[0030] (1) Standard solution preparation

[0031] Weigh 25 mg of bovine milk IgG, 50 mg of α-lactalbumin, 50 mg of bovine serum albumin, 100 mg of β-lactoglobulin, and 2.5 mg of lactoferrin and dissolve them in 500 ml of phosphate buffer. Divide the standard sample into Eppendorph test tubes, freeze and store between -25°C and -18°C, the shelf life can be kept for 3 months, and thaw on the day of use.

[0032] (2) Sample processing

[0033] When the sample is powder, dissolve 100-1000mg powder in 100ml phosphate buffer; when the sample is liquid, dilute the sample with phosphate buffer until the protein content is about 0.1%. If the protein content in the sample is lower than 0.1%, no dilution is required .

[0034] All samples were filtered with a 0.22 μm filter and then determined by high performance liquid chromatography.

[0035] (3) HPLC experimental conditions

[0036] Chromatographic column: 2 TSK G3000PW Xl Gel column series, with pre-column PW Xl (6mm×4cm),

[...

Embodiment 2

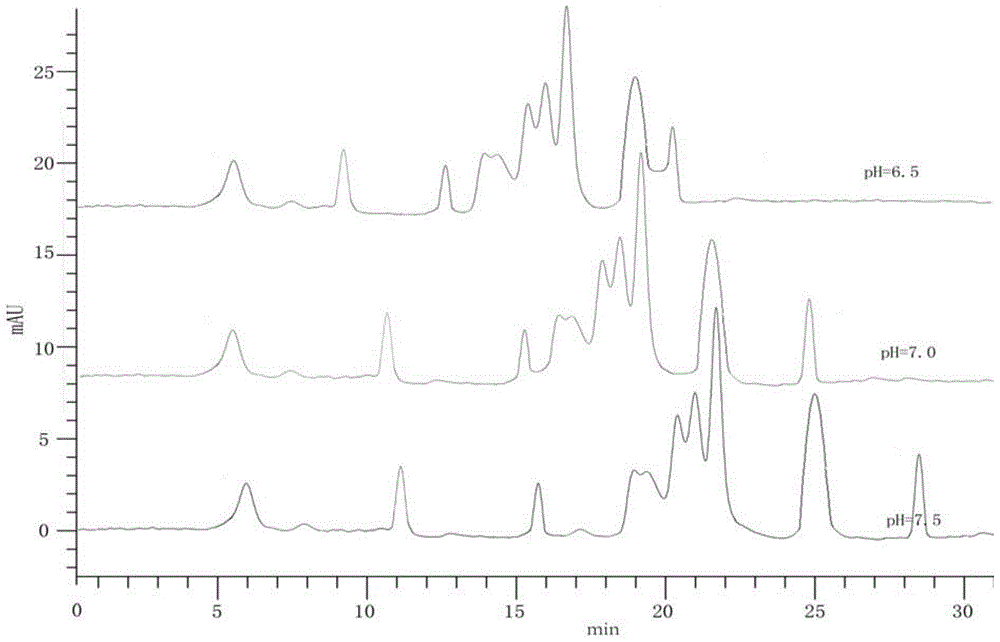

[0051] Buffer pH selection: by figure 2 It can be seen that the use of phosphate buffers with different pH values has an impact on component separation and peak eluting time. Through a series of pH gradient experiments, the optimal pH of phosphate buffer was finally determined to be 7.5.

Embodiment 3

[0053] This example uses the method of the present invention to detect whey protein components in a certain infant formula milk powder.

[0054] Reagent and material preparation:

[0055] Mobile phase preparation: add 470.0g deionized water, 413.4g acetonitrile, and 1.0ml trifluoroacetic acid below the liquid level of the chromatographic column.

[0056] The standard solutions were mixed in capped reagent bottles and filtered through a 0.22 μm membrane.

[0057] Sample treatment: Weigh 0.500g sample, dissolve it in phosphate buffer, and dilute to 100ml;

[0058] Preparation and detection of the measurement solution: take the treatment solution and pass it through a 0.22 μm filter membrane, and then use a high-performance liquid chromatograph for measurement.

[0059] The content of each component was calculated according to the announcement, and the results are shown in Table 1.

[0060] Table 1

[0061] component name retention time (min) content Milk I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com