Method for detecting content of effective rubber powder in rubber asphalt

A technology of rubber asphalt and detection method, which is applied in the direction of removing certain components, weighing, plastic recycling, recycling technology, etc., can solve the problem of reducing the performance of rubber asphalt, the content of effective rubber powder in rubber asphalt is not up to standard, adding rubber powder. low volume issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Three solvents (kerosene, trichlorethylene and n-heptane) were selected to dissolve rubber powder R (large vehicle tire rubber powder) and rubber asphalt AR respectively. Wherein, dissolving rubber powder R comprises the following steps:

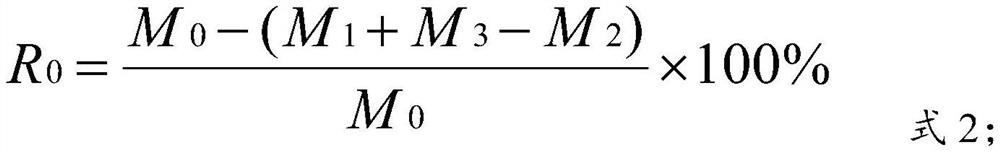

[0077] Mass is M 0 Mix the rubber powder with the solvent at 45°C, the mass ratio of the rubber powder to the solvent is 1:50, vibrate while mixing, the vibration speed is 400r / min, first pass through the centrifuge (speed 1500rpm) to preliminarily separate and precipitate the insoluble matter Drying quality M 1 , and then filtered through the precision filter equipment to obtain the total mass of the filter equipment M 2 , Filtration equipment and residue drying quality after filtration M 3 , the insoluble matter is considered as undissolved rubber powder.

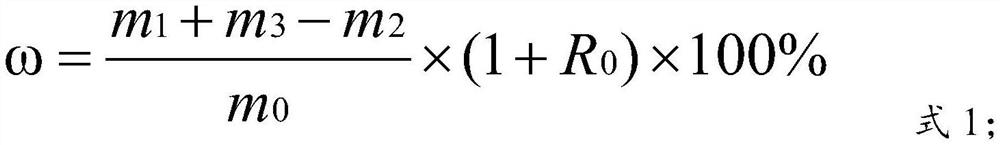

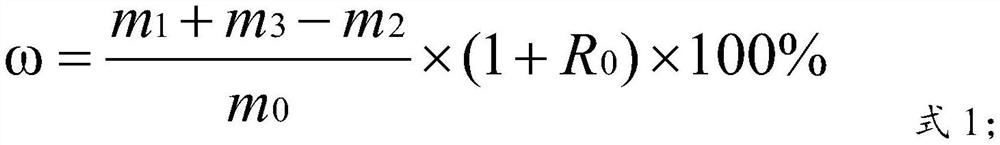

[0078] Calculate the solubility of rubber powder in rubber asphalt according to formula 2.

[0079]

[0080] The solubility of rubber powder in three different solvents i...

Embodiment 2

[0097] Trichlorethylene was selected as the solvent, and two groups of rubber asphalt samples from different projects were taken to test the amount of rubber powder. Calculation procedure is the same as example 1, wherein the solubility of rubber powder in trichlorethylene is taken as 4.87%, carries out parallel test respectively and obtains test result as follows:

[0098]

[0099] The results of the three groups of parallel tests were almost the same, and within the range of test error, the average value was taken as the final effective rubber powder content. Through the test method of the invention, the mixing amount of the main modifier rubber powder in the on-site rubber asphalt can be quickly and quantitatively detected, thereby evaluating the performance of the asphalt to a certain extent. The effective rubber powder content of sample B in Example 2 is low, which reminds users to pay attention to the performance of this kind of asphalt. Since the rubber powder of as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com