Method for processing artificial Indian handmade chenille ground mat

A processing method, chenille technology, applied to carpets, devices for coating liquid on the surface, textiles, etc., can solve the problems of hindering popularization, high price, and unsatisfactory, and achieve the effect of rough style and strong air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

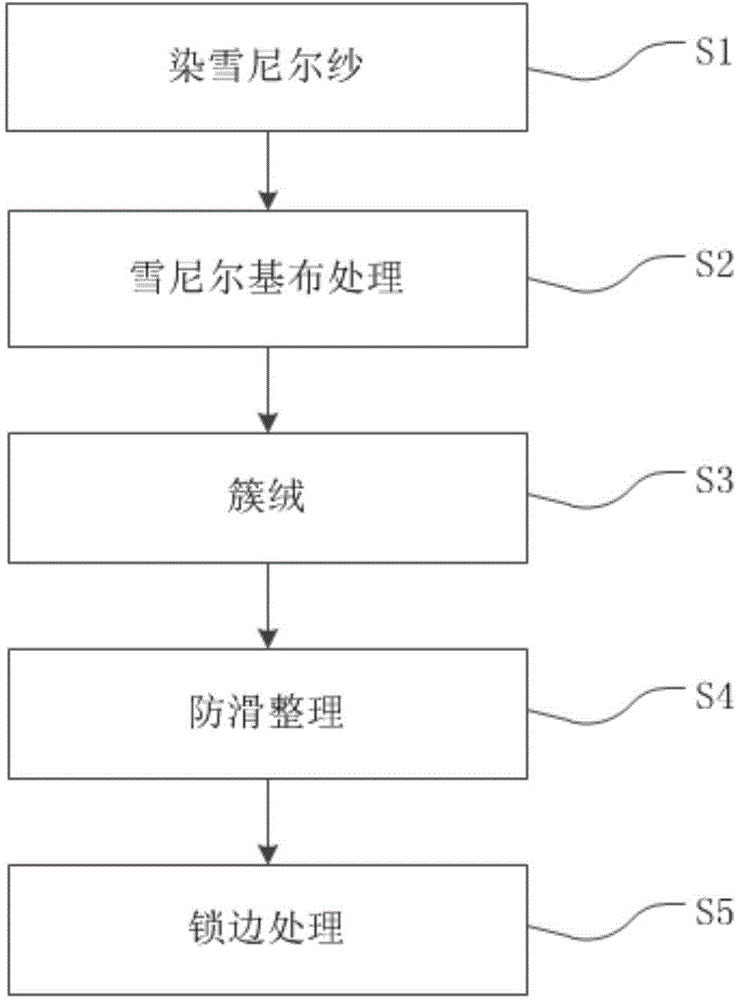

Image

Examples

Embodiment 1

[0028] The concrete steps of embodiment one are as follows:

[0029] Step 1. Dye 0.2 300D / 360F chenille yarn and 2.5 chenille yarn hank, color number Y00024.

[0030] Step 2. The dyed 2.5 chenille yarns are woven into the base fabric through a rapier loom; the woven base fabric is loosened into a pre-shrinking machine at 170° C. to complete the pre-shrinking treatment of the base fabric.

[0031] Step 3. Adjust the needle distance of the tufting machine to 1.6cm. The tufting needle needs to consider making the needle dry and the needle hole larger. The model used in this example is φ4.7×115×110×105 Yarn→rewinding yarn→hanging yarn→threading yarn, tufting, the process parameters are set to 6 stitches / 10cm, wool height 14mm, gram weight 1000g / m 2 .

[0032] Step 4. Carry out anti-skid finishing on the woven blanket, using environmentally friendly hot sol, the back glue temperature is 130 ° C, and the glue amount is 30 g / m 2 .

[0033] Step 5. Overlock the adhesive-backed bla...

Embodiment 2

[0034] The concrete steps of embodiment two are as follows:

[0035] Step 1. Dye 0.2 300D / 360F chenille yarn and 2.5 chenille yarn hank, the color number is Y00001.

[0036] Step 2. The dyed 2.5 chenille yarns are woven into the base fabric through a rapier loom; the woven base fabric is loosened into a pre-shrinking machine at 190° C. to complete the pre-shrinking treatment of the base fabric.

[0037] Step 3. Adjust the needle distance of the tufting machine to 1.6cm. The tufting needle needs to consider making the needle dry and the needle hole larger. The model used in this example is φ4.7×115×110×105 Yarn→rewinding yarn→hanging yarn→threading yarn, tufting, the process parameters are set to 8 stitches / 10cm, wool height 16mm, gram weight 1300g / m 2 .

[0038] Step 4. Carry out anti-skid finishing on the woven blanket, using environmentally friendly hot sol, the back glue temperature is 140 ° C, and the glue amount is 40 g / m 2 .

[0039] Step 5. Overlock the adhesive-bac...

Embodiment 3

[0040] The concrete steps of embodiment three are as follows:

[0041] Step 1. Dye 0.2 300D / 360F chenille yarn and 2.5 chenille yarn hank, the color number is Y00036.

[0042] Step 2. The dyed 2.5 chenille yarns are woven into the base fabric through a rapier loom; the woven base fabric is loosened into a pre-shrinking machine at 180° C. to complete the pre-shrinking treatment of the base fabric.

[0043] Step 3. Adjust the needle distance of the tufting machine to 1.6cm. The tufting needle needs to consider making the needle dry and the needle hole larger. The model used in this example is φ4.7×115×110×105 Yarn→rewinding yarn→hanging yarn→threading yarn, tufting, the process parameters are set to 7 stitches / 10cm, wool height 15mm, gram weight 1150g / m 2 .

[0044] Step 4. Carry out anti-skid finishing on the woven blanket, using environmentally friendly hot sol, the back glue temperature is 135 ° C, and the glue amount is 35 g / m 2 .

[0045] Step 5. Overlock the adhesive-b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com