One-way valve hydraulic glass cleaner

A glass cleaning and one-way valve technology, which is applied to cleaning equipment, window cleaning, household appliances, etc., can solve the problems of high labor intensity, low cleaning efficiency, and large labor consumption, and achieves the goal of reducing labor intensity and improving work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be further described below through the accompanying drawings and embodiments.

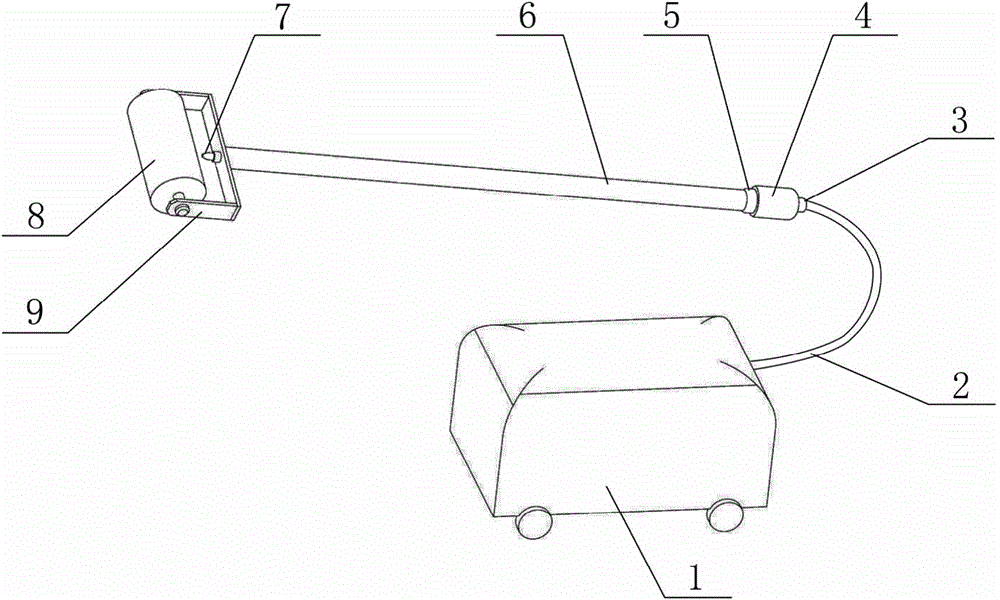

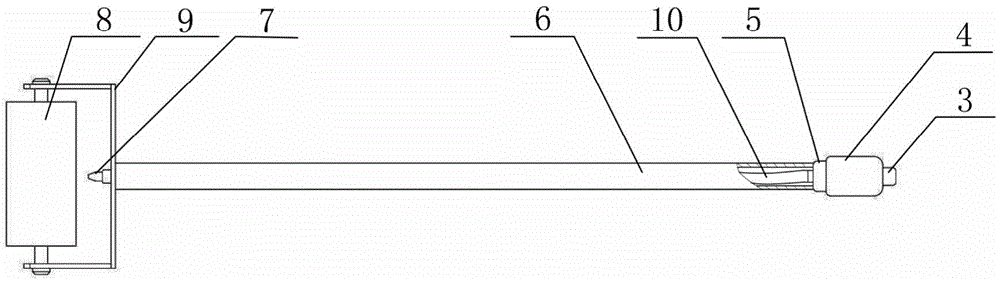

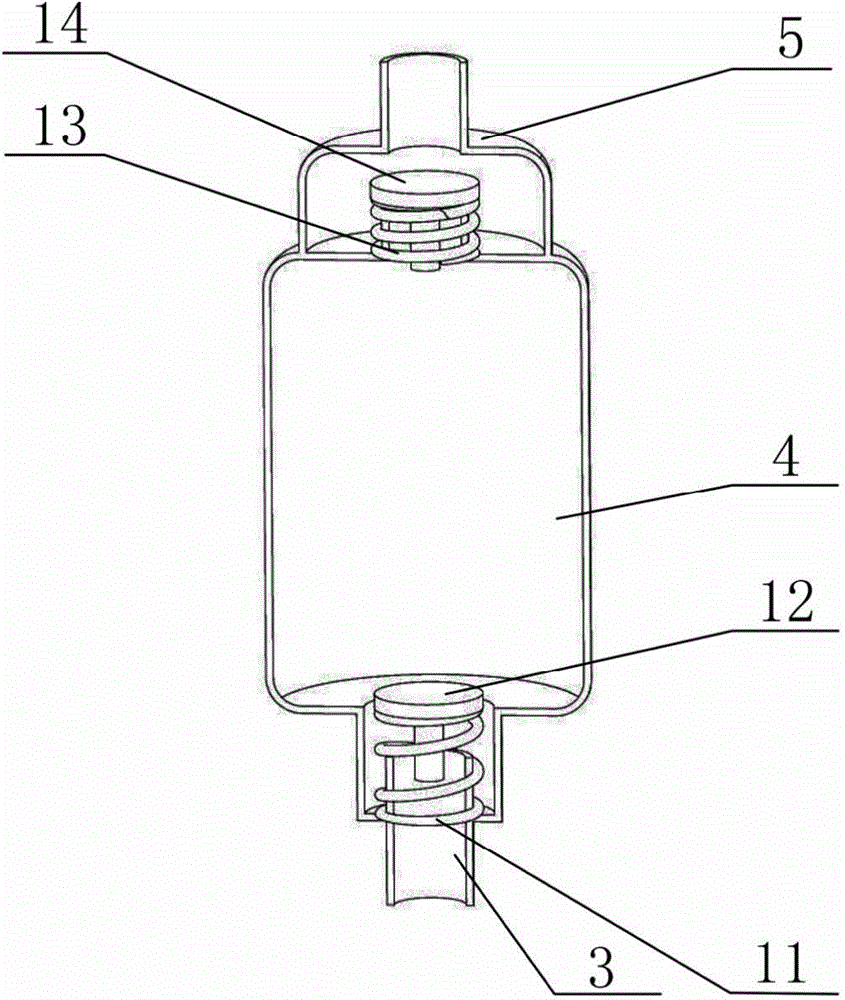

[0014] Such as Figure 1 to Figure 3 As shown, the one-way valve drum type glass washer of the present invention includes a water tank 1, a water inlet pipe 2, a rubber drum liquid bladder member, a water outlet pipe 10, a support rod 6, a nozzle 7, a rolling brush 8 and a support frame 9 . One end of the water inlet pipe 2 is inserted into the bottom of the water tank 1, and the other end is connected with the water inlet pipe joint 3. The water inlet pipe joint 3 and the water outlet pipe joint 5 are respectively connected and sealed with the openings at both ends of the rubber drum liquid bag 4. One end of the support rod 6 is connected with the water outlet pipe. The outer wall of the joint 5 is welded, the other end is welded with the support frame 9, the outlet pipe 10 is placed in the support rod 6, one end of the outlet pipe 10 i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap