Stamping mold and workpiece positioning device thereof

A technology of positioning device and stamping die, which is applied in the field of stamping dies, can solve the problems of low return and avoidance accuracy of the positioning device, increase production cost, waste mold space, etc., and achieve the effects of improving the timeliness of avoidance, avoiding space waste, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

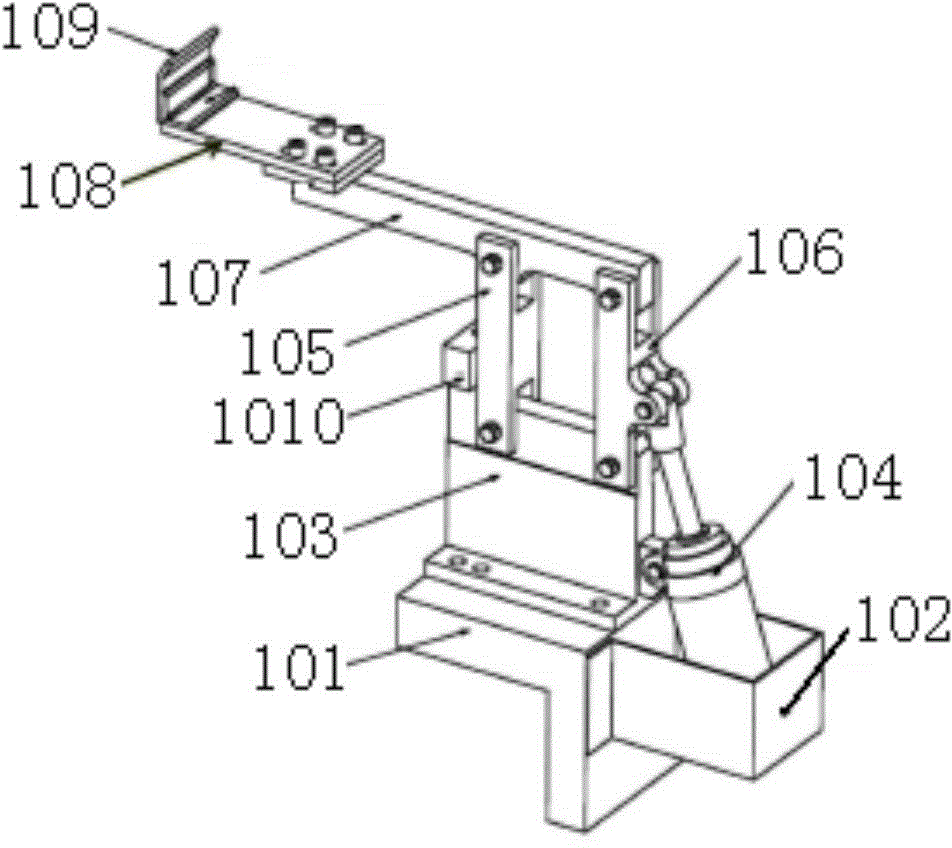

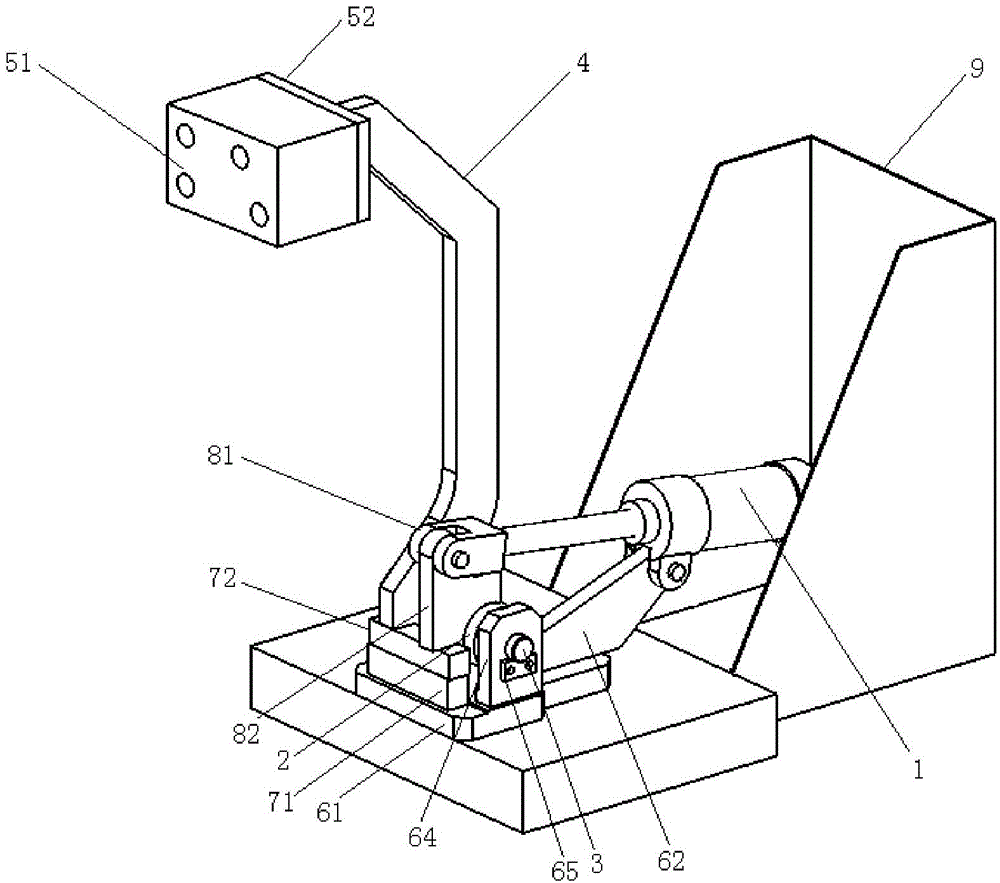

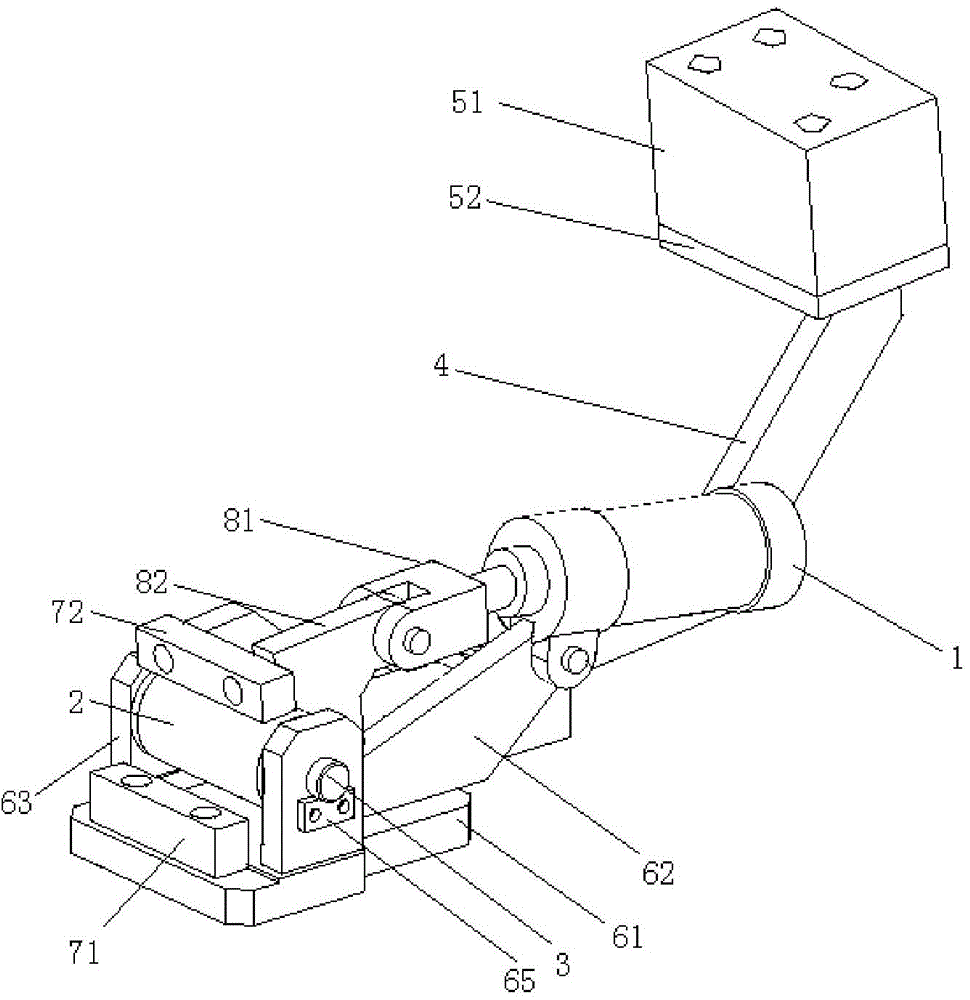

[0042] The core of the present invention is to provide a workpiece positioning device for a stamping die, which is expected to have a relatively simple structure and a small volume, thereby reducing production costs and avoiding waste of die space. Another core of the present invention is to provide a stamping die including the above workpiece positioning device.

[0043] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0044] Please refer to Figure 2-5 , in a specific embodiment, the workpiece positioning device provided by the present invention is used for stamping dies, the workpiece positioning device includes a mounting assembly fixed to the lower mold base, the fixed end of the telescopic cylinder 1 is fixedly connected to the mounting assembly, And its telescoping end is installed with guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com