Automatic conveying device

A conveying device and conveying belt technology, applied in the field of automated conveying devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention in conjunction with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

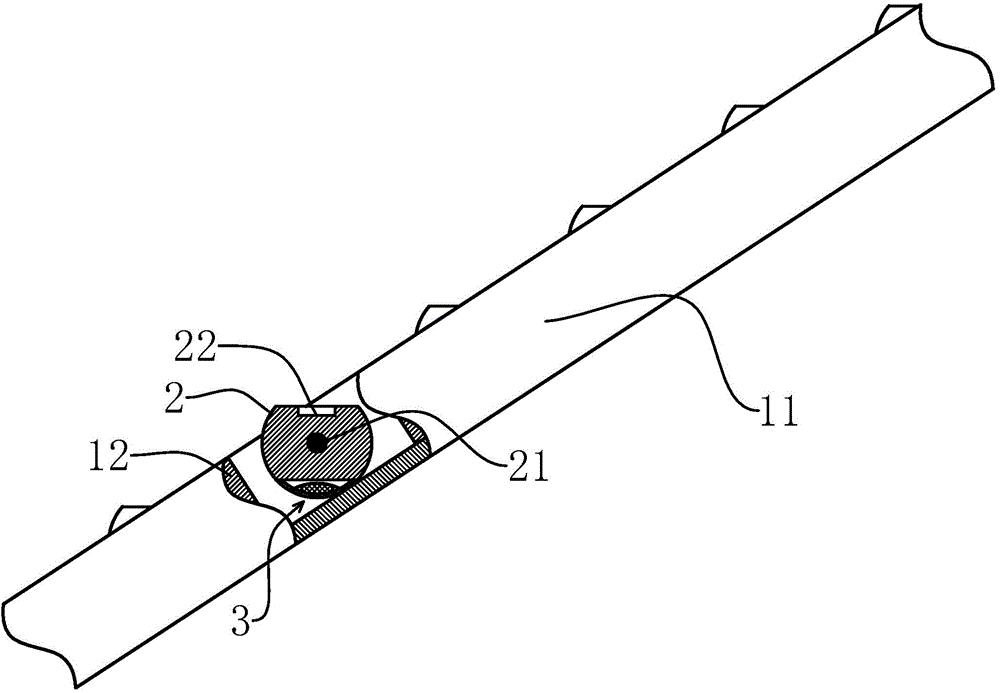

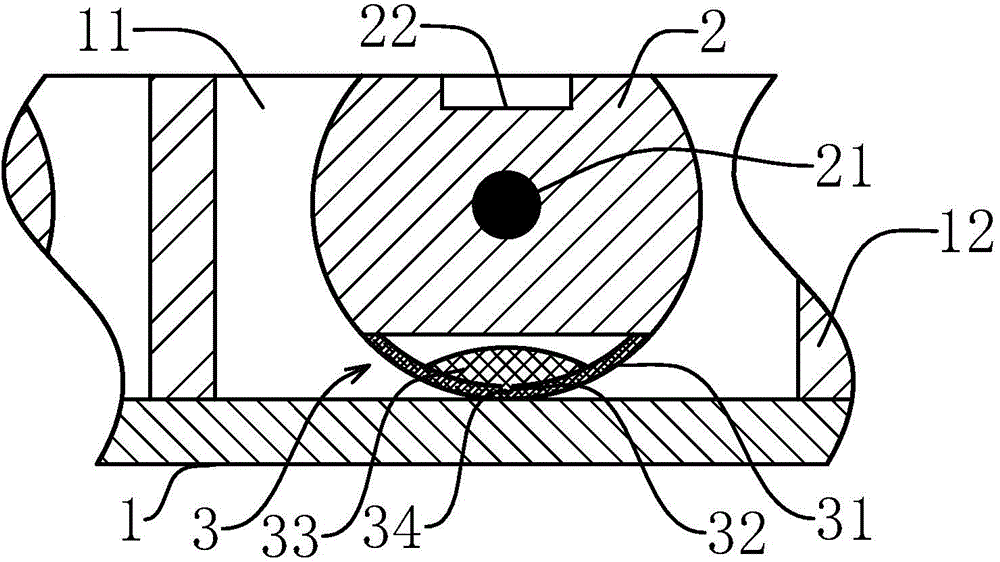

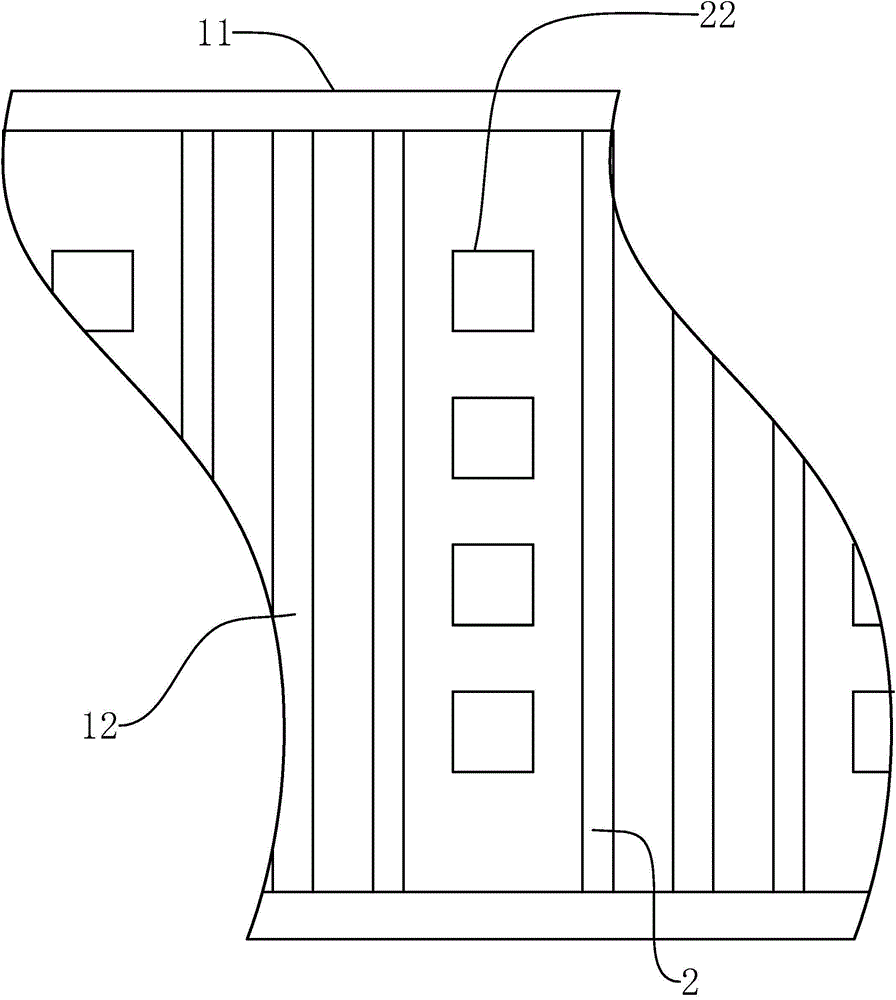

[0024] Such as Figure 1-3 As shown, an automated conveying device of the present invention includes a conveyor belt 1, and also includes two ribs 11, the two ribs 11 are arranged parallel to each other on the conveying surface of the conveyor belt 1, and the ribs 11 are along the conveyor belt 1 The conveying direction is set, and it also includes a carrier plate 2. The carrier plate 2 is arranged between the two ribs 11 through a rotating shaft 21, and the rotating shaft 21 is perpendicular to the rib 11, and the top of the carrier plate 2 has a loading slot 22, A counterweight device 3 is detachably connected to the bottom of the plate 2, and the direction of the slot of the loading slot 22 can be adjusted by adjusting the counte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com