Guide mechanism of full-automatic optical fiber winding machine

The technology of a guiding mechanism and a winding machine is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., which can solve the problems of affecting the quality of optical fibers, unable to lift the optical fibers, and not tight enough between the optical fibers. To achieve the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

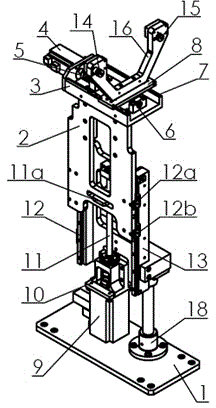

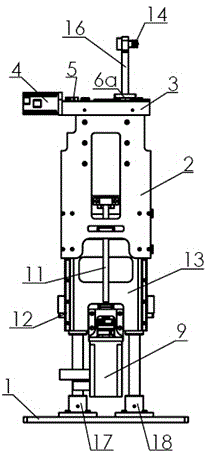

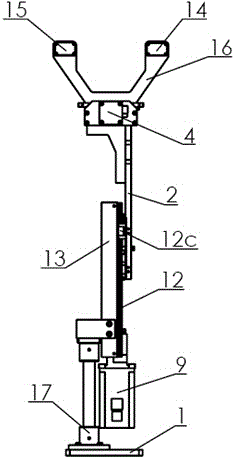

[0028] Such as Figure 1-Figure 4 A fully automatic optical fiber winding machine guide mechanism shown, the x-axis moving mechanism guided by the optical fiber winding machine, the z-axis moving mechanism used for guiding the optical fiber winding machine, the optical fiber winding guide wheel, and the installation part of the x-axis moving mechanism , z-axis moving mechanism installation part and guide wheel installation part. The z-axis moving mechanism is used to drive the optical fiber winding guide wheel to move up and down, and to lift the optical fiber when the optical fiber winding guide wheel moves upward. The x-axis moving mechanism is used to drive the optical fiber winding guide wheel to move to the left or right, so that the optical fiber winding guide wheel drives the optical fiber to start winding.

[0029] Specifically, the x-axis moving mechanism include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com