A Method for Improving the Wettability of Metal Surfaces Using High Energy Beam Texturing

A technology of wettability and texture, which is applied in the field of metal surface treatment and surface treatment, and can solve the problems of increasing the effective contact area between glass and metal, poor wettability, and low connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The specific steps for improving the wettability of borosilicate glass on the surface of Kovar alloy by electron beam texturing are as follows:

[0051] (1) After the Kovar alloy plate is ground sequentially with 200# to 1200# metallographic sandpaper, it is ultrasonically cleaned with acetone and alcohol solution, dried and placed in a desiccator;

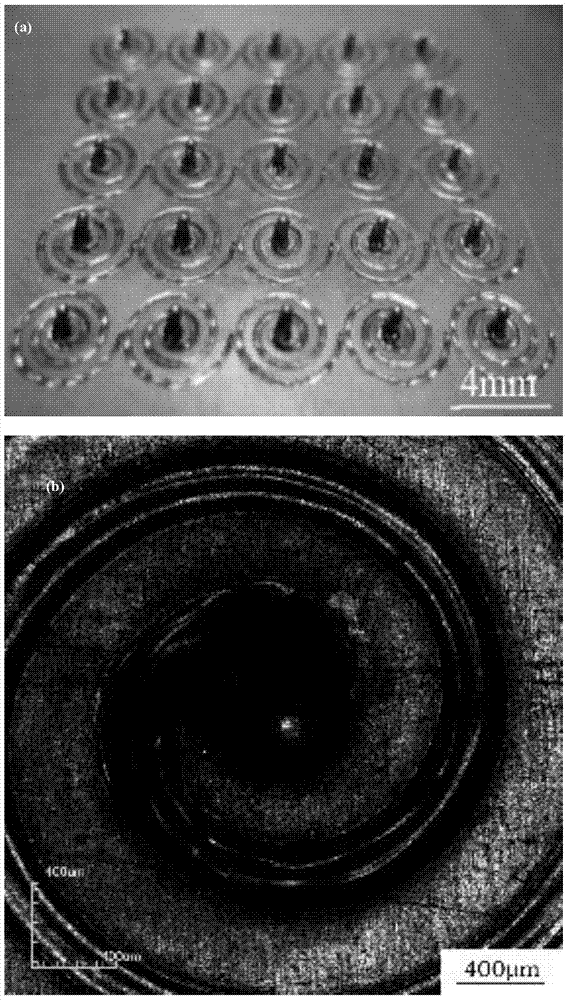

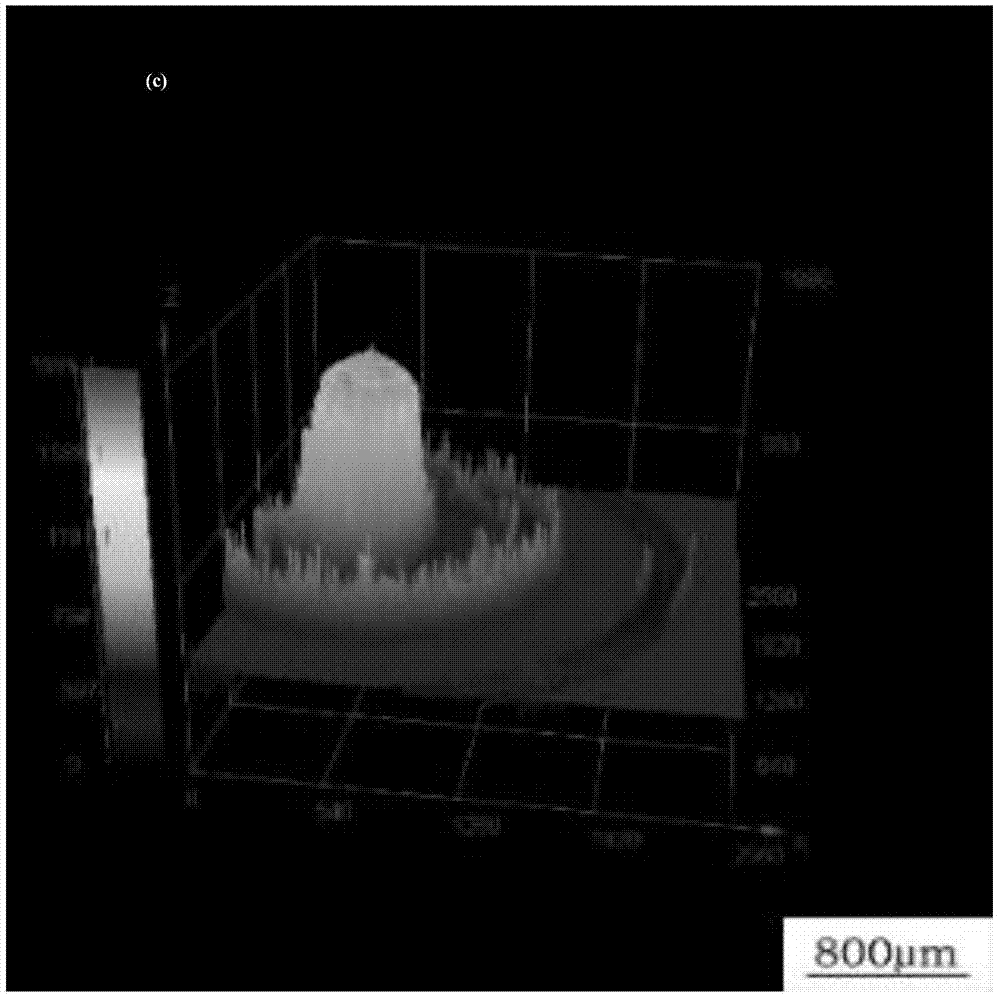

[0052] (2) Electron beam texturization: the Kovar alloy is texturized by electron beams, and two texturized shapes, helical and hexagonal, are obtained, such as figure 1 and figure 2 shown;

[0053] (3) In the atmospheric environment, the Kovar alloy sample is oxidized with a resistance furnace to obtain a composition of Fe 3 o 4 and Fe 2 o 3 oxide film;

[0054] (4) Heat borosilicate glass above the softening temperature, measure the wetting angle of borosilicate glass on the surface of Kovar alloy, and the relationship between the wetting angle of borosilicate glass on the surface of Kovar alloy with different surf...

Embodiment 2

[0056] (1) After the Kovar alloy plate is ground sequentially with 200# to 1200# metallographic sandpaper, it is ultrasonically cleaned with acetone and alcohol solution, dried and placed in a desiccator;

[0057] (2) Fiber laser texturization: use PLY-20M SCANLAB 10 fiber laser to texturize Kovar alloy, and obtain lattice texturization morphology with hole spacing of 0.3mm, 0.4mm, 0.5mm, 0.6mm and 0.7mm , polishing the textured Kovar alloy, the textured appearance is as follows image 3 shown;

[0058] (3) In the atmospheric environment, the Kovar alloy sample is oxidized with a resistance furnace to obtain a composition of Fe 3 o 4 and Fe 2 o 3 oxide film;

[0059] (4) After heating the borosilicate glass from room temperature to 1000°C and keeping it warm for 20 minutes, cool it to room temperature with the furnace, and measure the wetting angle of the borosilicate glass on the surface of the Kovar alloy. The relationship curve between the wetting angle of the surface...

Embodiment 3

[0061] (1) After the Kovar alloy plate is ground sequentially with 200# to 1200# metallographic sandpaper, it is ultrasonically cleaned with acetone and alcohol solution, dried and placed in a desiccator;

[0062] (2) Femtosecond laser texturing: After polishing the Kovar alloy plate in step (1), adopt TC-22A type yttrium-doped fiber femtosecond laser to texturize the Kovar alloy, and the obtained hole spacing is respectively 0.05mm, 0.10mm, 0.15mm, 0.20mm and 0.25mm lattice roughening morphology, the textured Kovar alloy is polished, the textured appearance is as follows Figure 4 shown;

[0063] (3) In the atmospheric environment, the Kovar alloy sample is oxidized with a resistance furnace to obtain a composition of Fe 3 o 4 and Fe 2 o 3 oxide film;

[0064] (4) Heat the borosilicate glass from room temperature to 1000°C for 20 minutes, then cool it to room temperature with the furnace, and measure the wetting angle of the borosilicate glass on the surface of the Kovar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com