A heat-resistant material for high temperature measurement and its preparation method

A heat-resistant material and high-temperature technology, which is applied in the field of new materials for blast furnace temperature measurement, manufacturing, and production of new materials, can solve problems such as the inability to meet the needs of high-temperature measurement, and achieve a good market space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 (chemical composition 1):

[0028] 1. Process implementation

[0029] 1) Electric furnace smelting and casting

[0030] The specific implementation is as follows:

[0031] Add low-carbon steel scrap, ferro-tungsten, ferro-molybdenum, ferro-chromium, ferro-vanadium, and nickel plates into a 500KG medium-frequency induction furnace in order to melt;

[0032] Argon blowing in the furnace;

[0033] Adjust the chemical composition of the molten steel, and pass the chemical detection and analysis before the furnace. After the composition is qualified, add deoxidizer aluminum strips, and raise the temperature to 1600--1650 ° C to prepare for tapping;

[0034] Crush the rare earth to a size of 20mm, and put the rare earth baked at 280°Cx4H in the ladle after the steel is baked, and pour the ladle with molten steel at 1600--1650°C;

[0035] After calming down for 10-20 minutes, start casting when the steel temperature reaches 1500-1550°C.

[0036] 2) Annealing ...

Embodiment 2

[0051] Embodiment 2 (chemical composition 2):

[0052] 1. Process implementation

[0053] Process implementation is the same as that in Example 1.

[0054] 2. Test results

[0055] element

C

Si

mn

Cr

Ni

Re

Element

0.47

2.36

0.49

25.68

19.32

0.07

element

W

Mo

V

S

P

Fe

Element

3.69

1.83

0.79

0.020

0.018

the remaining

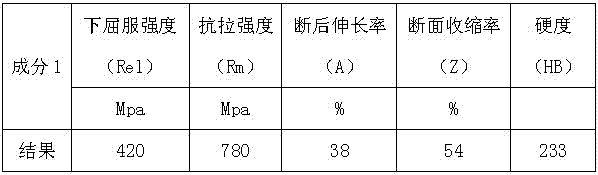

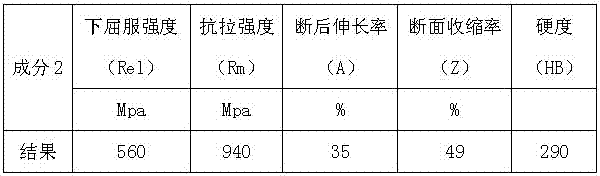

[0056] 2) Mechanical properties

[0057]

[0058] 3) High temperature performance test

[0059] The high-temperature performance test results show that the high-temperature performance index of this composition material is obviously better than that of 310S and 310S stainless steel, and the high-temperature resistance can reach 1150°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com