Helical gear transmission 360-degree dual-axis synchronous damping shaft

A technology for damping shafts and helical gears, which is applied to pivot connections, structural components of portable computers, instruments, etc., can solve the problems of imperfect operation, cumbersome installation and disassembly operations, and restricting the thinning development of electronic equipment such as notebooks. Perfect connection and smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

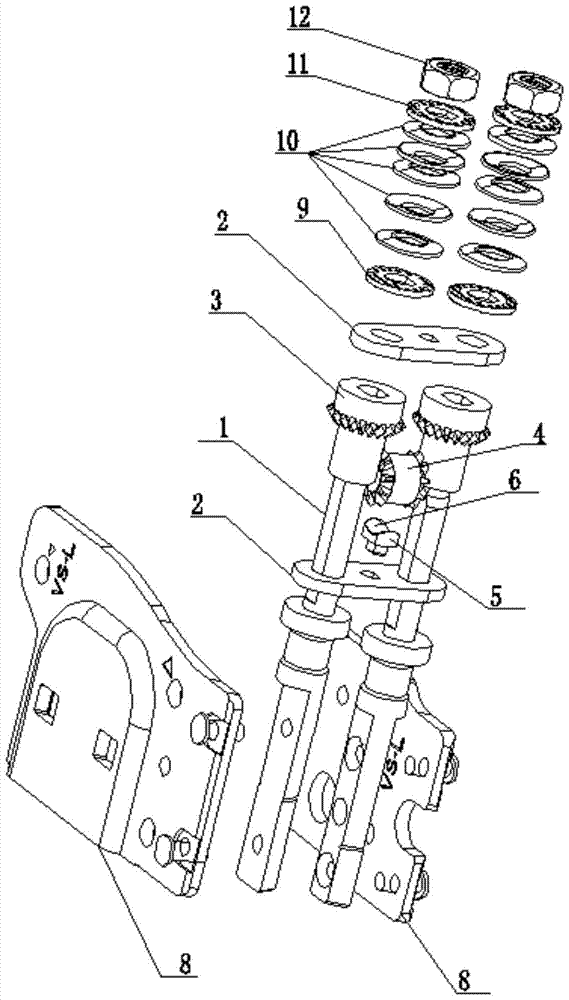

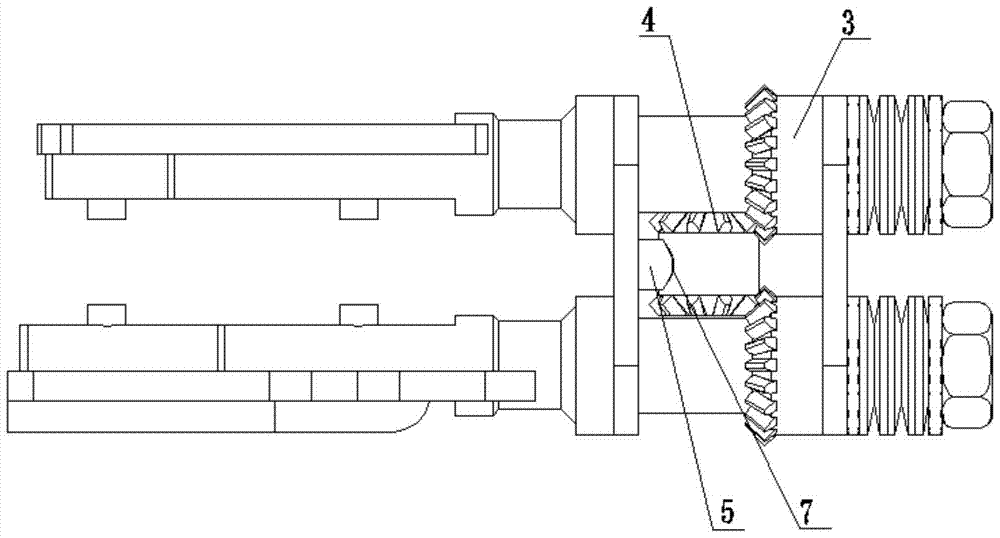

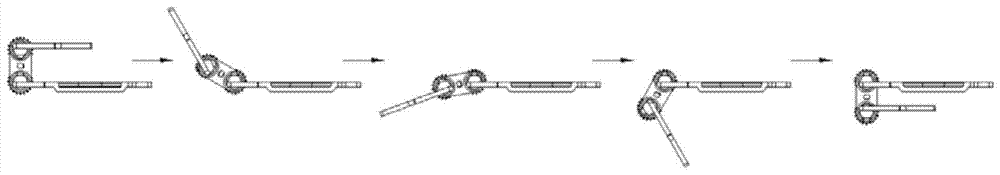

[0022] Such as figure 1 , figure 2 and image 3 As shown, a helical gear transmission type 360-degree dual-axis synchronous damping shaft, including two shaft cores 1 and at least two connecting plates 2, corresponding to each shaft core is provided with a driving helical gear 3, each driving helical gear sleeve fixed on the corresponding shaft cores, wherein the two connecting plates are positioned on both sides of the two said driving helical gears, and sleeved on the two said shaft cores, so that the radial distance between the two said shaft cores is set distance, and the two shaft cores can axially stop and rotate freely in the circumferential direction relative to the two connecting plates; in addition, a transmission helical gear 4 is provided, and the transmission helical gear is positioned on the two connecting plates and the two connecting plates. In the accommodation space surrounded by two driving helical gears, both ends of the driving helical gear mesh with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com