Mechanical emergency shut-off valve

A cut-off valve, mechanical technology, applied in the direction of mechanical equipment, valve details, valve devices, etc., can solve the problems of mechanical emergency cut-off valve installation, inconvenient debugging, complex structure, etc., to achieve simple and convenient debugging, simple and reliable cooperation, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to have a clearer understanding of the technical solutions, objectives and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

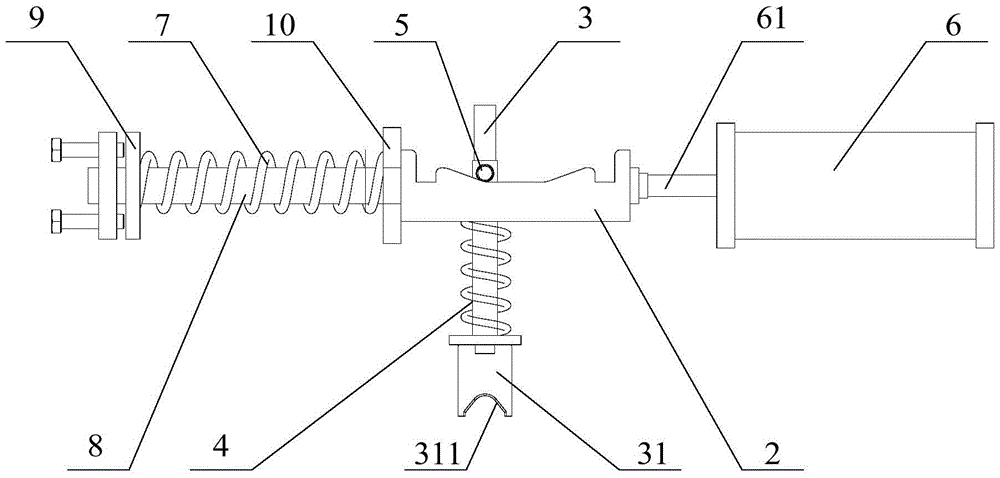

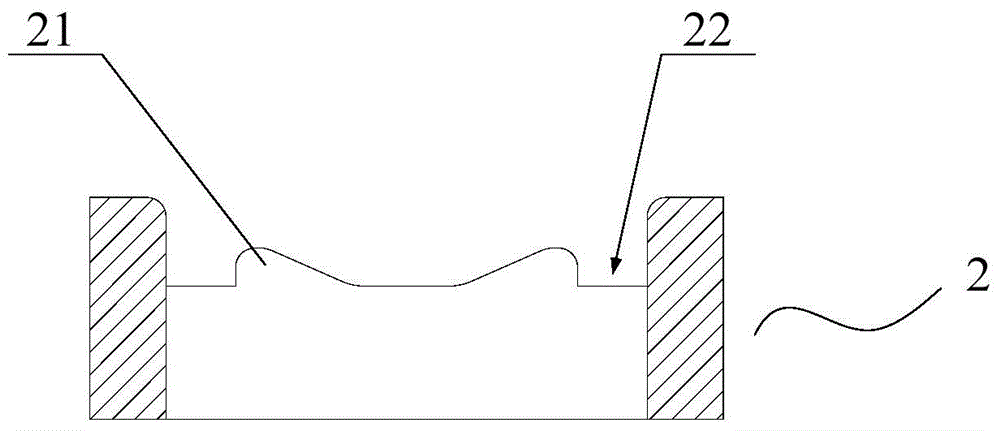

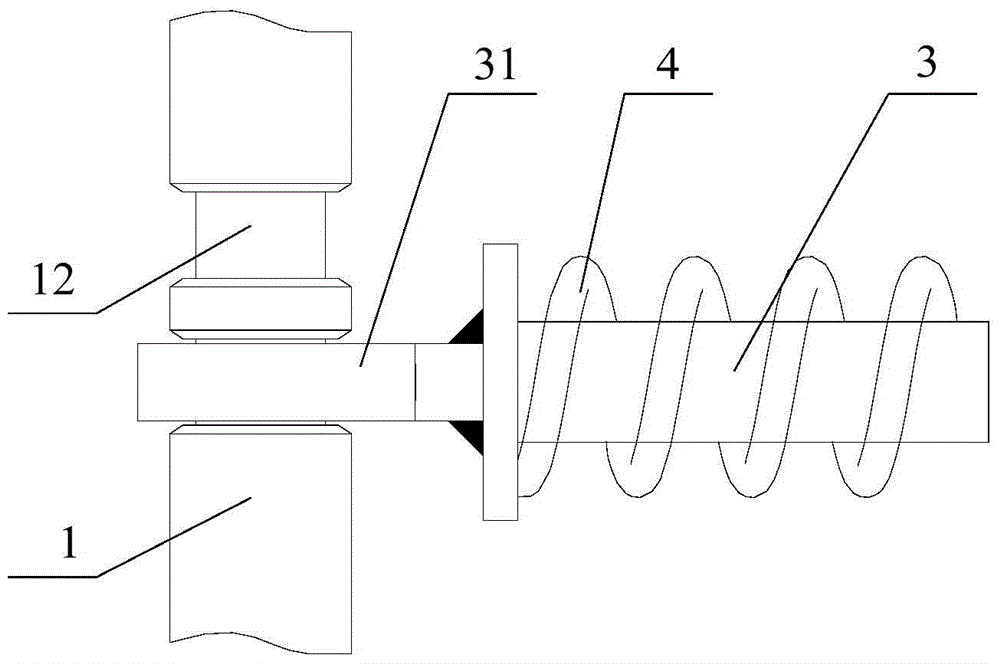

[0021] Such as figure 1 As shown, the present invention provides a mechanical emergency shut-off valve, including: a valve core 1, an adjustment mechanism and a self-locking plunger 3, wherein the valve core 1 is provided with an annular opening self-locking slot 11 and a closing Self-locking slot 12; the adjustment mechanism includes two lateral drive parts and an adjustment bracket 2 clamped between the two lateral drive parts, and the adjustment bracket 2 is provided with guide rails 21 that are high on both sides and low in the middle and concave in the lateral direction , and the two ends of the guide rail 21 are provided with a concave limit card slot 22; the self-locking plunger 3 can move longitudinally through the adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com