Low-frequency cyclic loading test device

A low-cycle repetitive load and test device technology, which is applied in the direction of measuring devices, vibration tests, and machine/structural component tests, can solve the waste of manpower, material resources, financial resources and time, and the non-reusable use of ground beams and distribution beams. Implementation inconvenience and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical content of the present invention will be further described below, but it is not intended to limit the essence of the present invention.

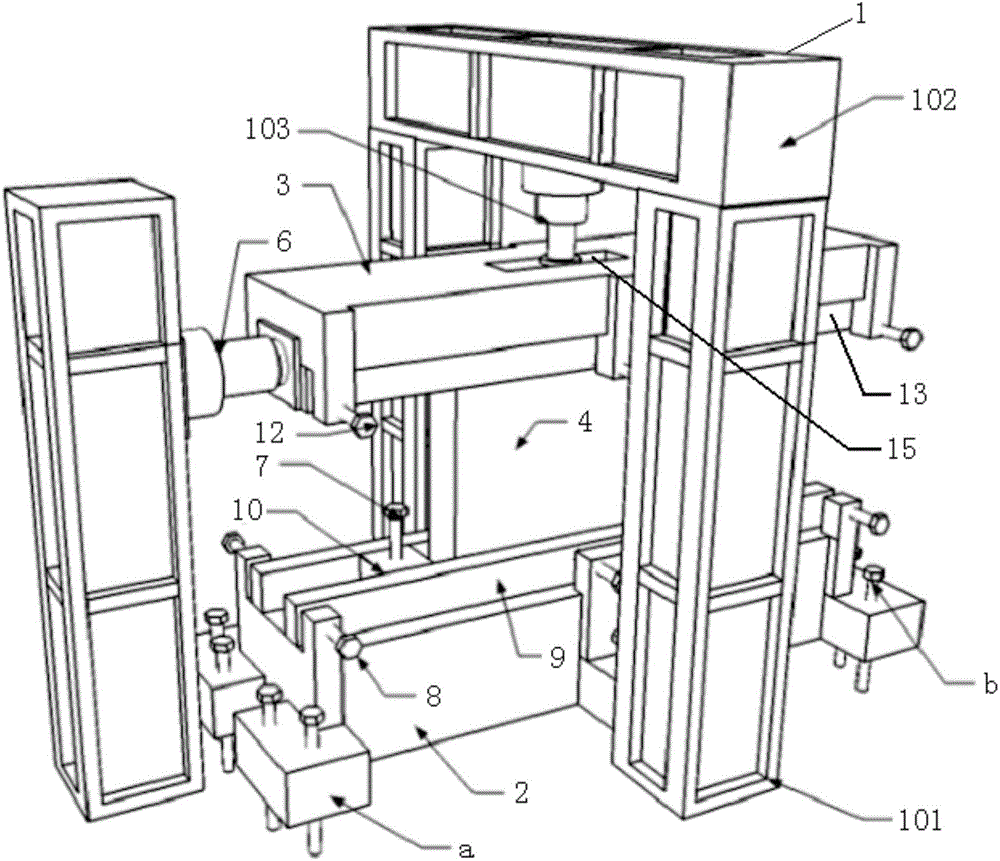

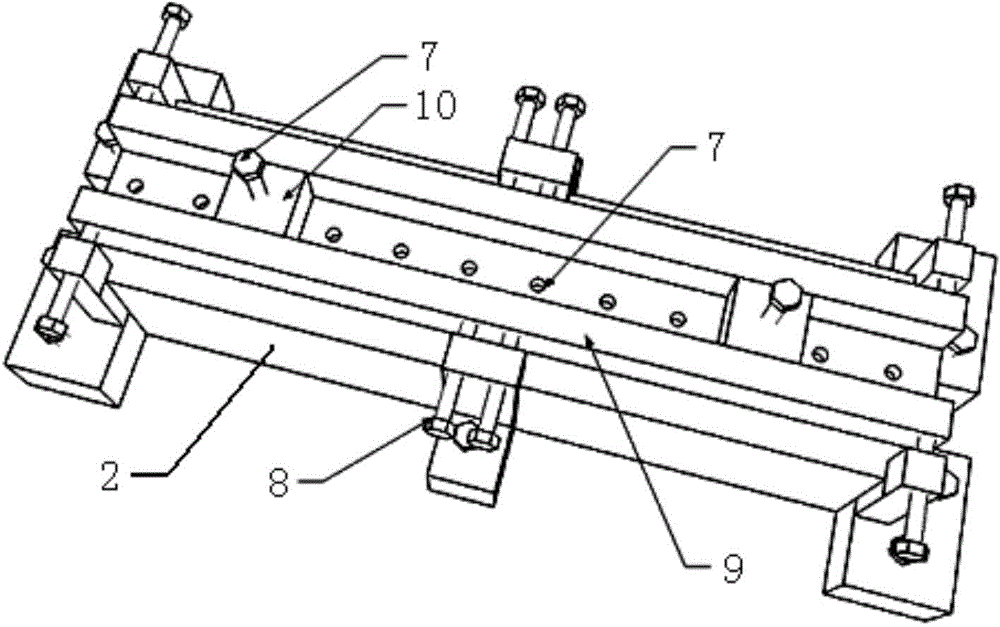

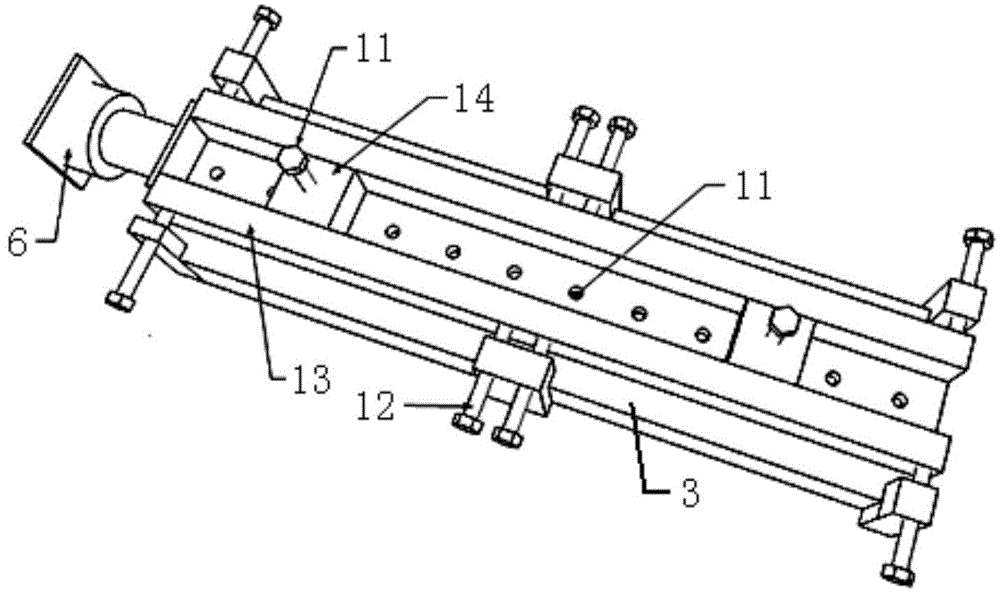

[0027] figure 1 It is a structural schematic diagram of the low cycle repeated load test device of the embodiment of the present invention; figure 2 is a structural schematic diagram of the ground beam of the embodiment of the present invention; image 3 is a schematic structural view of the distribution beam of the embodiment of the present invention; Figure 4 is a structural schematic diagram of an axial pressure jack according to an embodiment of the present invention; Figure 5 is a schematic diagram of the fixed structure of the test piece to be tested in the embodiment of the present invention; Image 6 It is a structural schematic diagram of the first longitudinal limit slider and the second longitudinal limit slider according to the embodiment of the present invention.

[0028] like figure 1 As shown, a ki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com