Cleaning device for steel structure building

A technology for cleaning devices and buildings, applied in snow traps and other directions, can solve the problems of large energy consumption, weight-heavy steel structure buildings collapse, collapse, etc., and achieve the effect of avoiding excessive resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further elaborated below with reference to the accompanying drawings and specific embodiments.

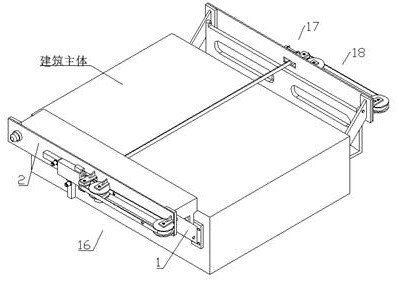

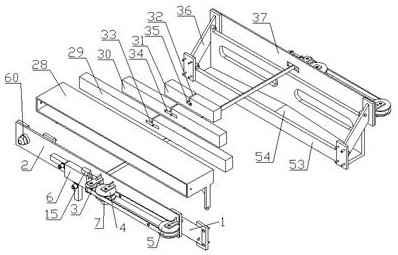

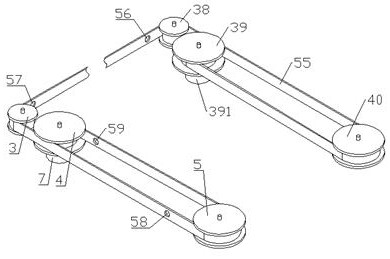

[0019] like Figure 1-6As shown, a cleaning device for a steel structure building includes a front support frame 1, a front support base 2, a No. 1 pulley 3, a No. 2 pulley 4, a No. 3 pulley 5, a front storage box 6, a front brake motor 7, a front push-pull Slot 8, front storage slot 9, No. 1 push rod motor 10, No. 2 push rod motor 11, front push-pull column 12, front column electromagnet 13, front permanent magnet column 14, front identification camera 15, cleaning part 16, auxiliary part 17. The dragging part 18, the left and right parts of the front end of the main body of the building are respectively fixed with a front support frame 1, the front ends of the two front support frames 1 are jointly installed with a horizontal front support seat 2, and the front end of the front support seat 2 is from the left. The horizontal No. 1 pulley 3, N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com