System for dividing and transforming torque for vehicle operation and vehicle including same

A torque and vehicle technology, applied to the sealing of the engine, the transmission device, the fluid transmission device, etc., can solve the problems of low torque converter efficiency, increased production costs, and large torque transfer of the torque converter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

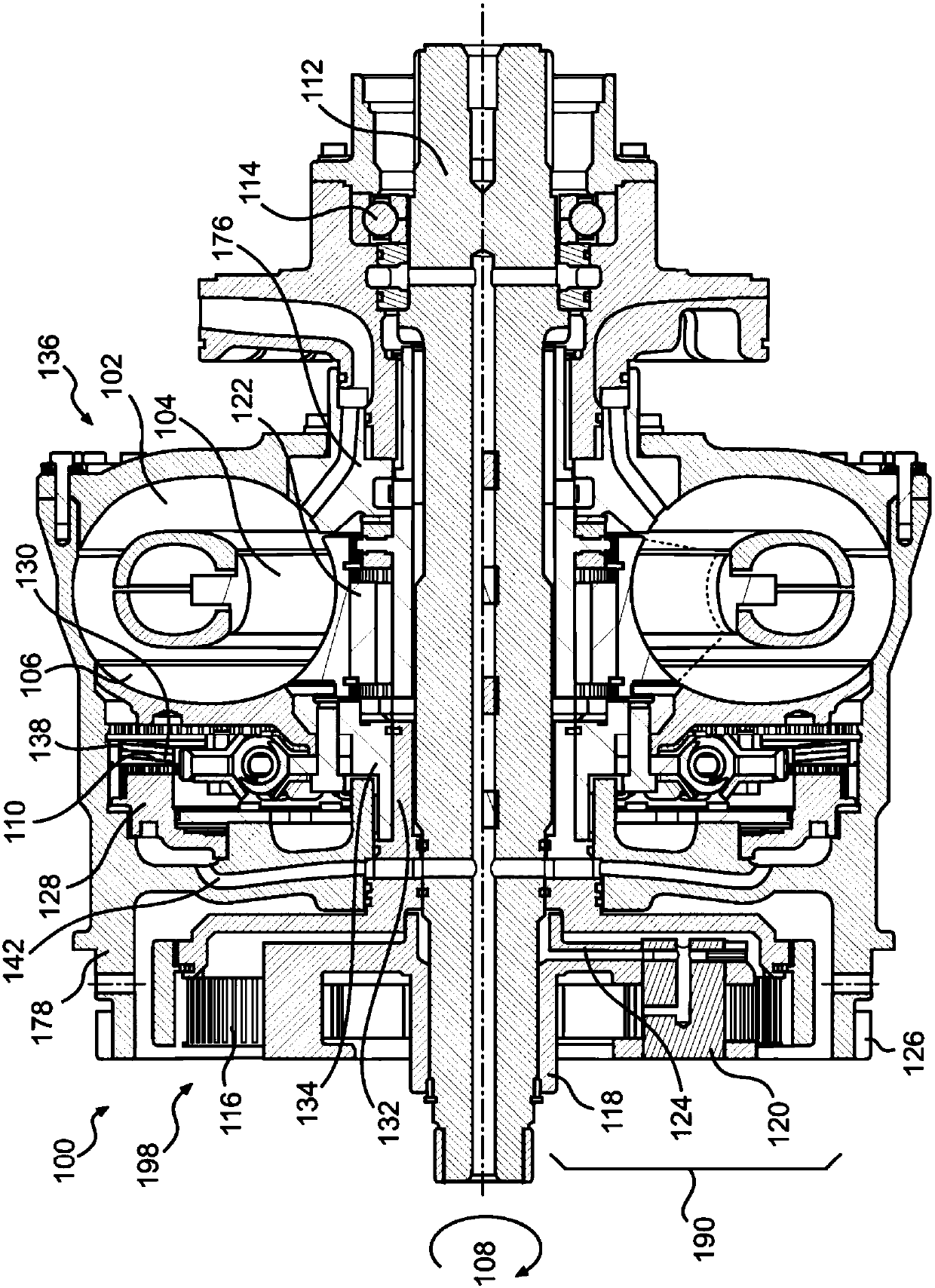

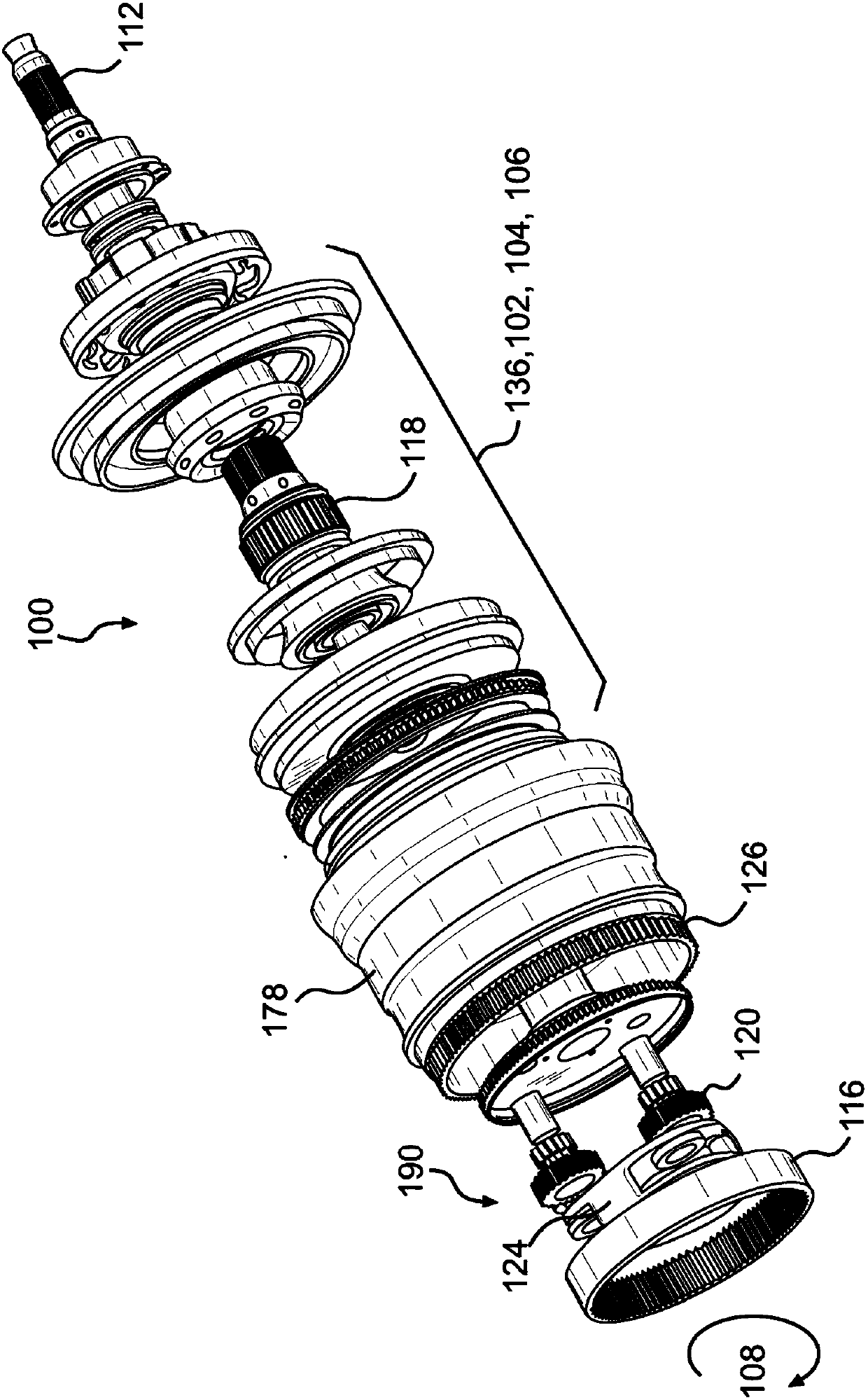

[0016] The invention will now be described with reference to the drawings, wherein like reference numerals refer to like parts throughout. Embodiments of the present invention advantageously provide a torque converter having a torque divider with a lock-up clutch that improves efficiency, improves fuel economy, and reduces hydraulic losses. Furthermore, a torque converter having a torque divider with a lock-up clutch reduces the overall size of the components and also reduces production costs. Finally, the torque converter and torque divider with lock-up clutch of the present invention are suitable for use with a vehicle.

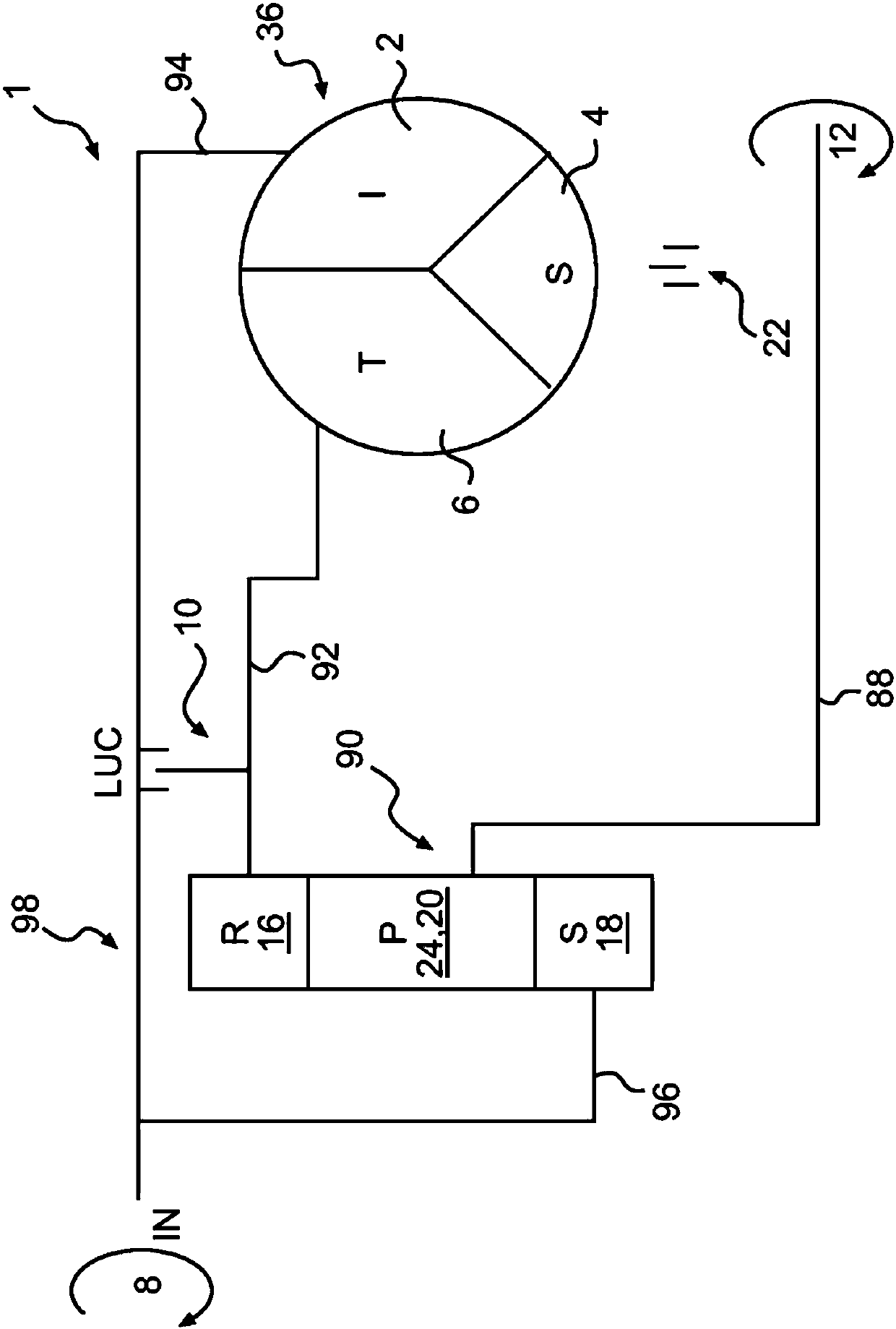

[0017] figure 1 A torque converter and torque divider according to an aspect of the invention are shown. specifically, figure 1 A torque converter and torque divider 1 including a prime mover input 8 and a torque converter output 12 is shown. The torque converter and torque divider 1 also includes a torque divider 98 that divides the torque from the pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com