Paint spraying shielding jig and paint spraying shielding method

A jig, non-painting technology, used in spraying devices, coatings, devices for coating liquids on surfaces, etc. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below with reference to the drawings and embodiments.

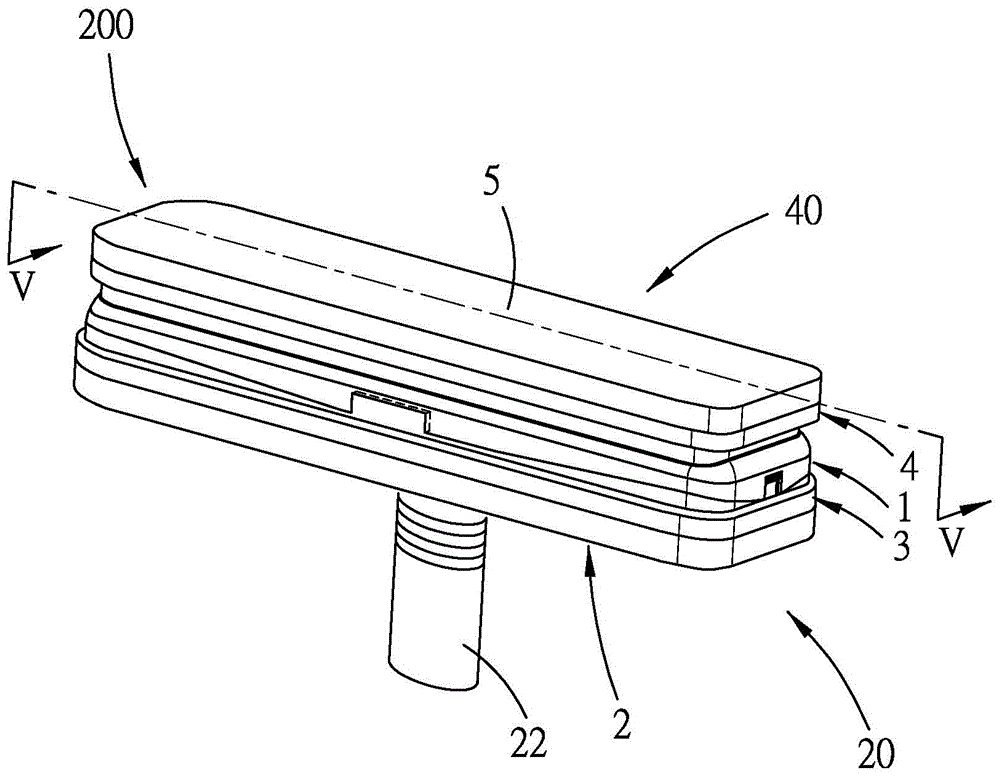

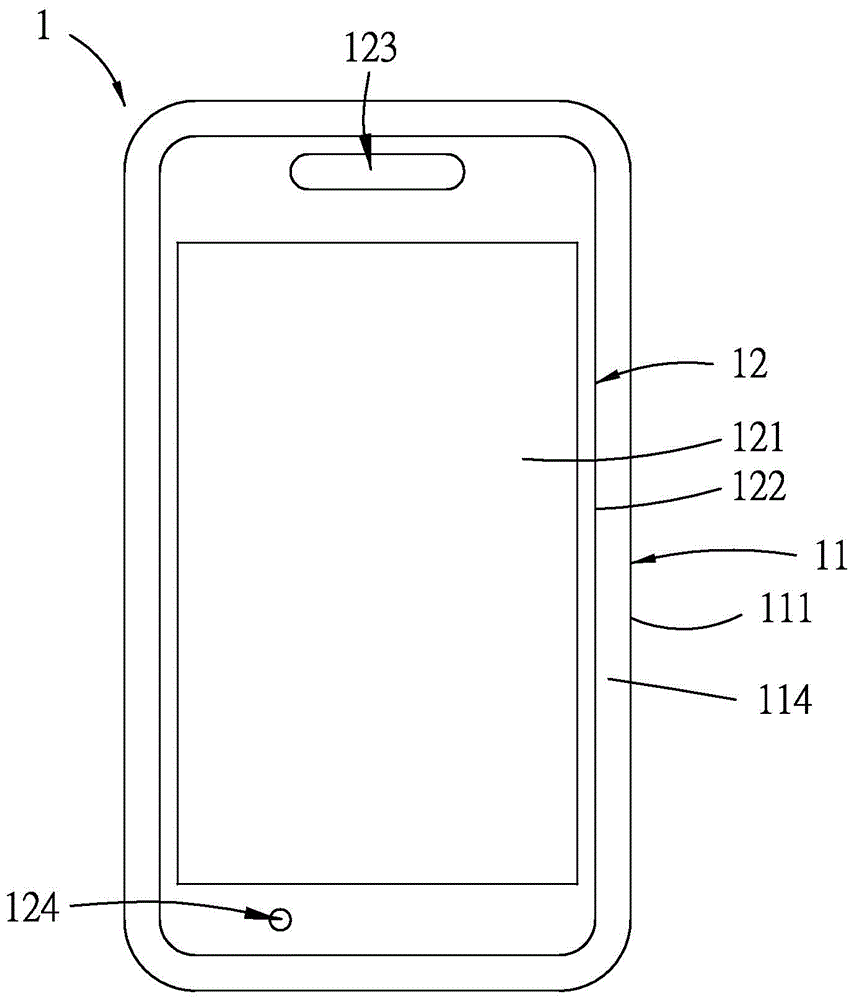

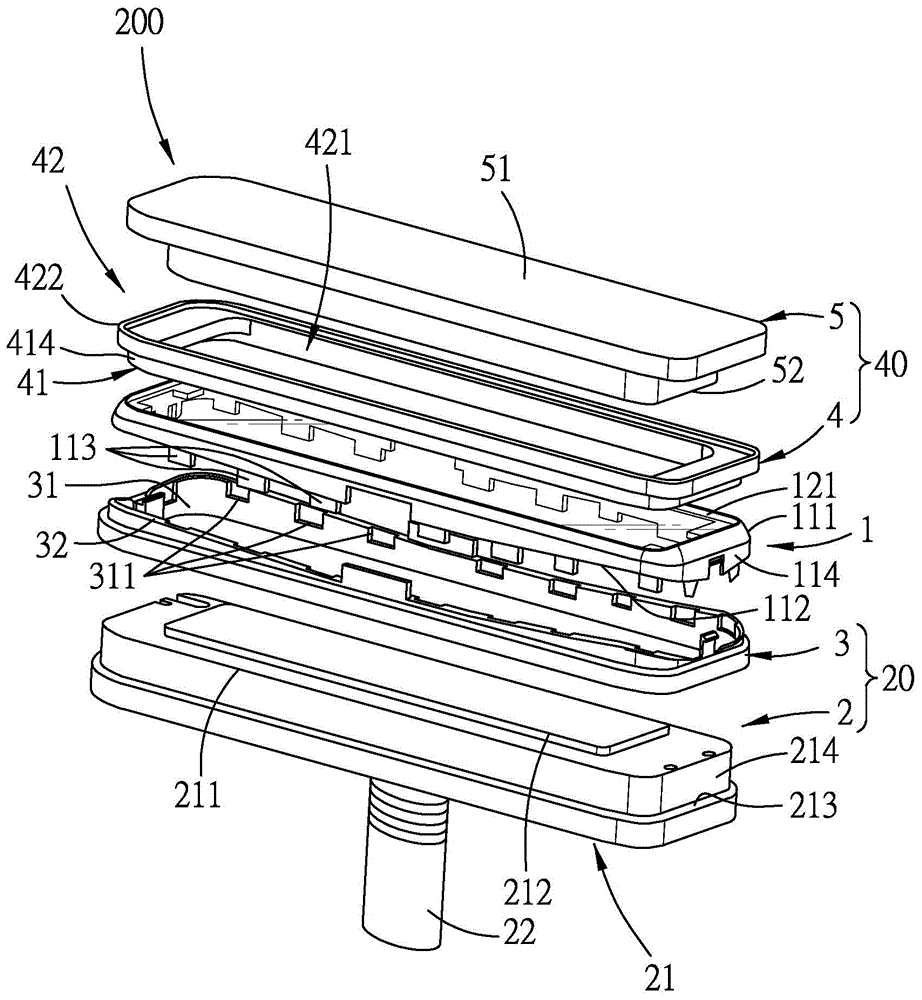

[0034] Refer to figure 1 , figure 2 and image 3 , Is an embodiment of the paint spray masking jig of the present invention, the paint spray masking jig 200 is suitable for holding a piece 1 to be painted for painting. The part to be painted 1 of this embodiment is illustrated by the front cover of, for example, a smart phone. The part to be painted 1 includes a housing 11 with a rectangular box shape and four corners with corners, and a glass plate integrated in the middle of the housing 11 12. The housing 11 includes a housing 111 and a plurality of clamping pieces 113 protruding from the end surface 112 of the rear end of the housing 111. The housing 11 is formed on the glass plate 12 by, for example, in-mold molding, and the housing 11 can be clamped and positioned on a back cover (not shown) through a clamping piece 113. The housing 11 includes a surface 114 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com