Surgical instrument cleaning machine

A technology for surgical instruments and cleaning machines, applied in the field of medical instruments, can solve the problem of wasting the working time of medical staff, and achieve the effects of complete functions, convenient use, and ease of work difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

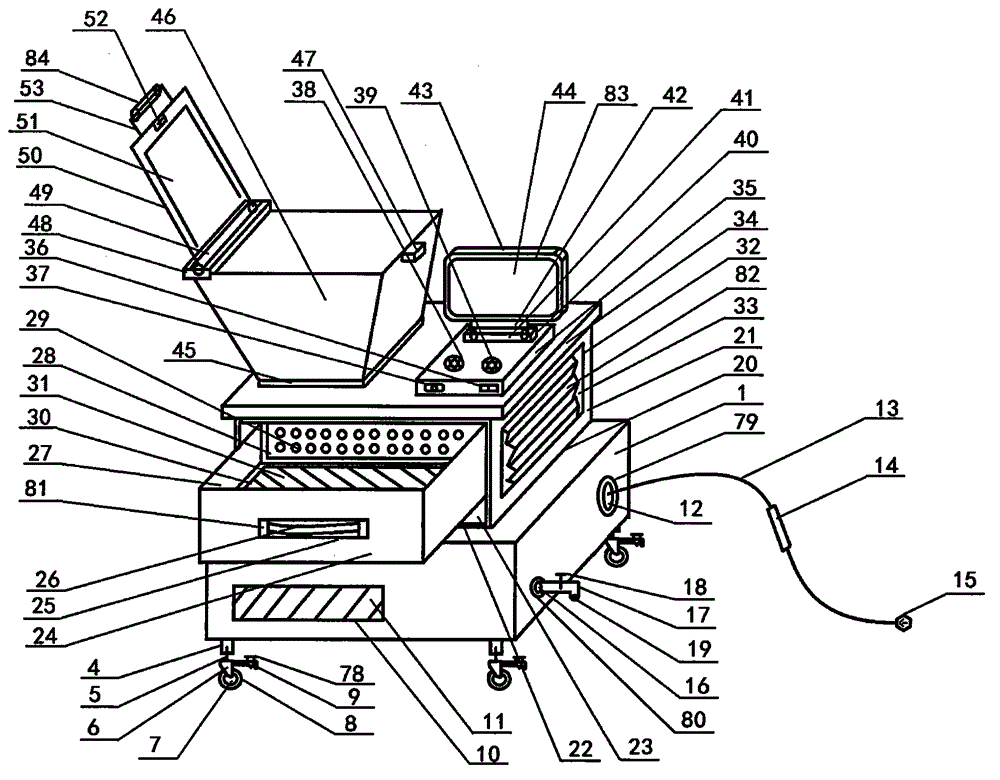

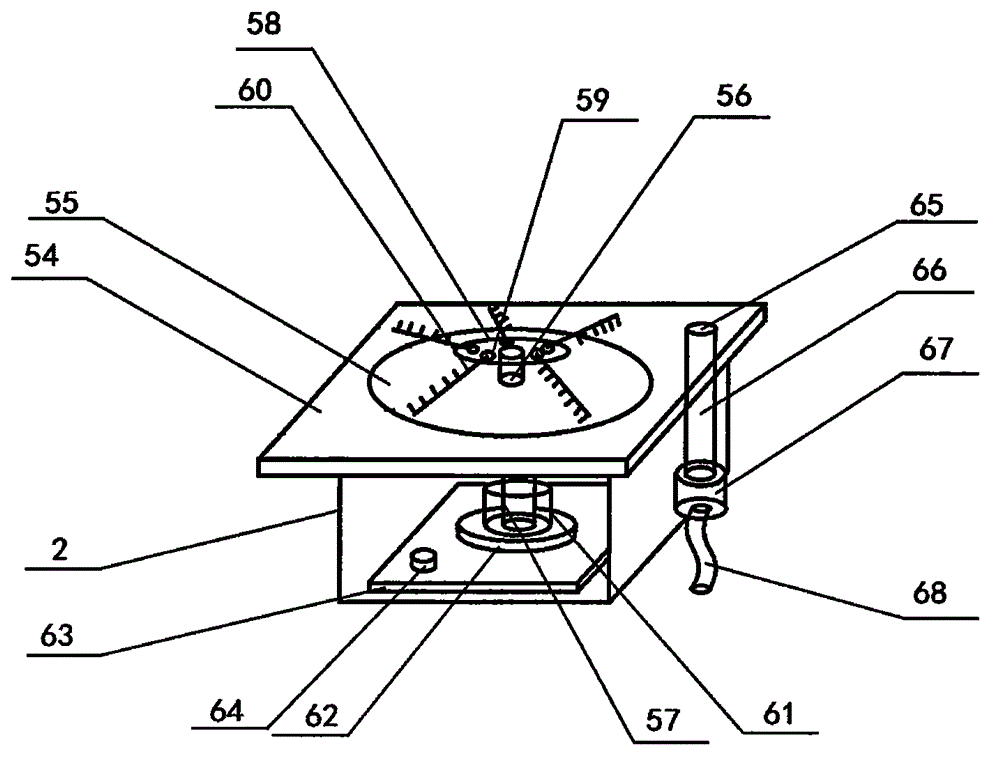

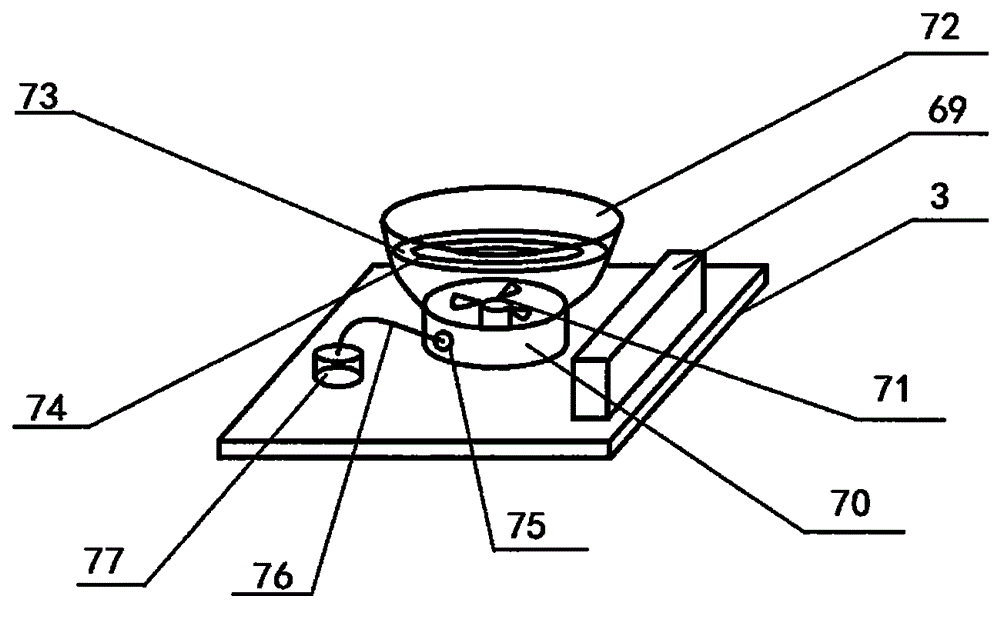

[0023] The surgical instrument cleaning machine of the present invention will be described in detail below with reference to the drawings.

[0024] Such as figure 1 As shown, the surgical instrument washing machine of the present invention includes a washing machine main body 1, a disinfection and cleaning device 2 and a heating and drying device 3. A support leg 4 is provided on the lower side of the washing machine main body 1, and an intermediate connection is provided on the lower side of the support leg 4 Rod 5, the lower side of the middle connecting rod 5 is provided with a roller guard 6, the lower side of the roller guard 6 is provided with a universal wheel fixing device 7, and the outer side of the universal wheel fixing device 7 is provided with a universal moving wheel 8, a roller guard 6 The right side is provided with a stepping brake lever 9, the front end of the washing machine body 1 is provided with a heat insulation plate fixing frame 10, and the heat insulatio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap