Horizontal processing machine

A processing machine, horizontal technology, applied in the direction of metal processing machine parts, metal processing, metal processing equipment, etc., can solve the problems of twisting and deformation of the machine base 11, troublesome operation, insufficient rigidity of the machine base 11, etc., and achieve lowering of the center of gravity position, Increase stability, improve machining accuracy and machining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to enable your examiner to have a further understanding of the present invention, the preferred embodiments are hereby given together with the accompanying drawings, and are described in detail as follows:

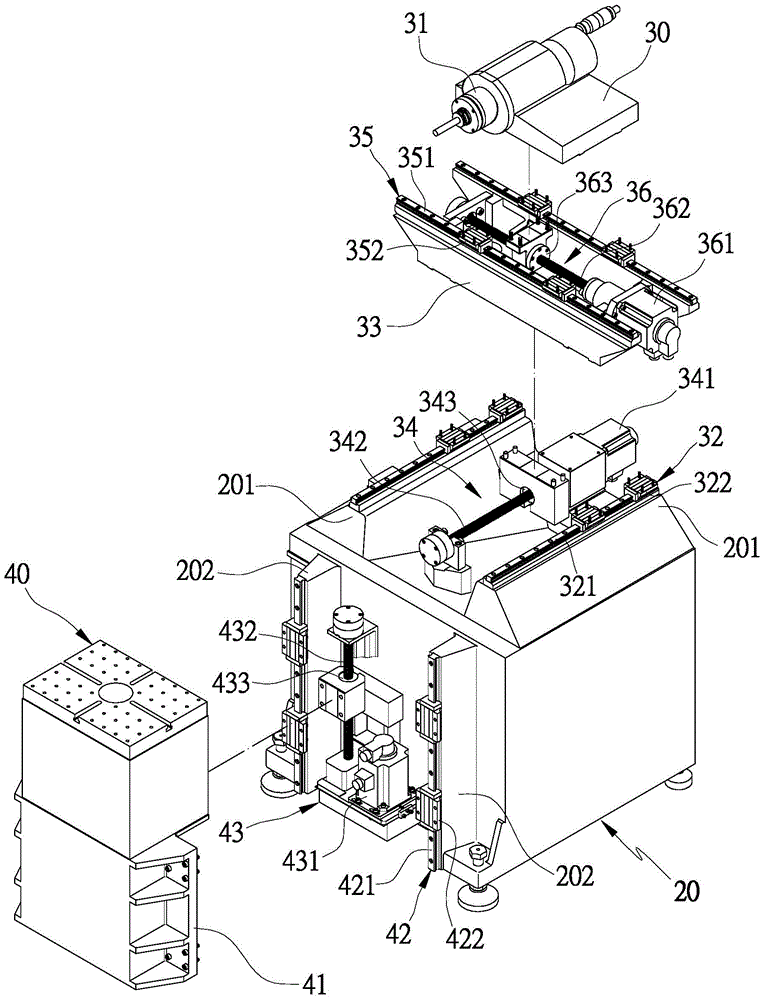

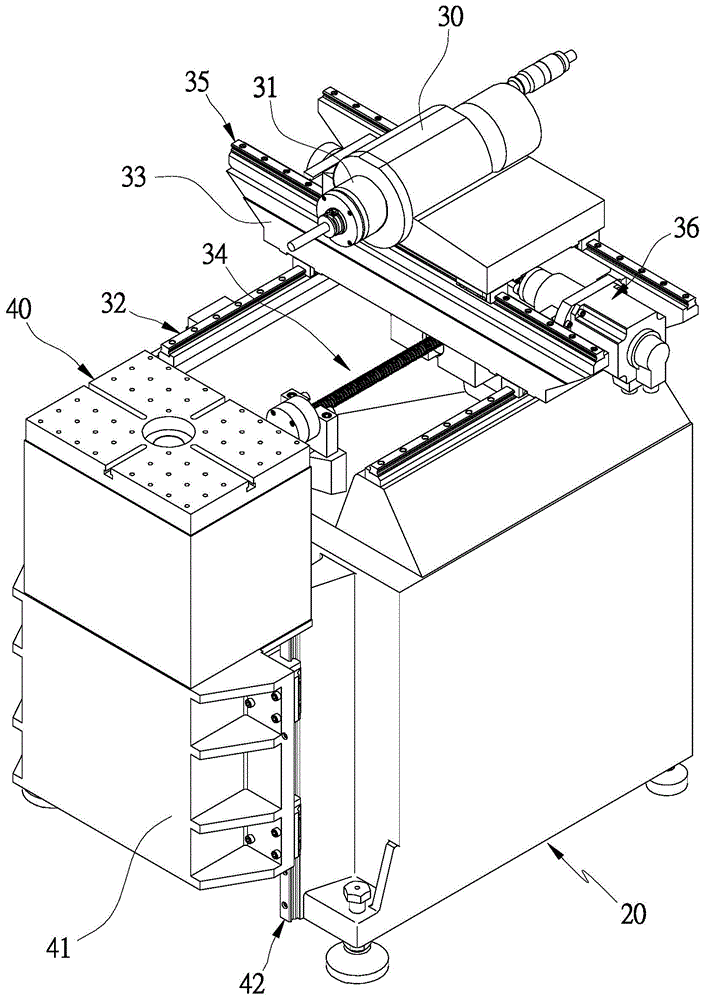

[0038] see figure 2 , image 3 , Figure 4 As shown, the horizontal processing machine of the present invention is provided with a top surface and side surfaces on a machine base 20, and a spindle base 30 is set up on the top surface of the machine base 20 for installing a horizontal machining spindle 31, and Use at least one displacement mechanism to drive the spindle seat 30 and the processing spindle 31 to perform at least one horizontal displacement; The first mounting portion 201 is provided with a first slide rail group 32 configured with a first slide rail 321 and a first slide block 322 in a first horizontal direction for erecting a moving seat 33, and a first displacement mechanism 34 Drive the moving base 33 to move back and forth in the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com