Rack mounting method for pile legs and rack mounting device

The technology of an installation device and installation method, which is applied to water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of too many hoisting times of pile leg racks, save equipment and labor costs, shorten operation cycles, and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention can have various changes in different embodiments without departing from the scope of the present invention, and that the descriptions and illustrations therein are illustrative in nature and not intended to limit the present invention. invention.

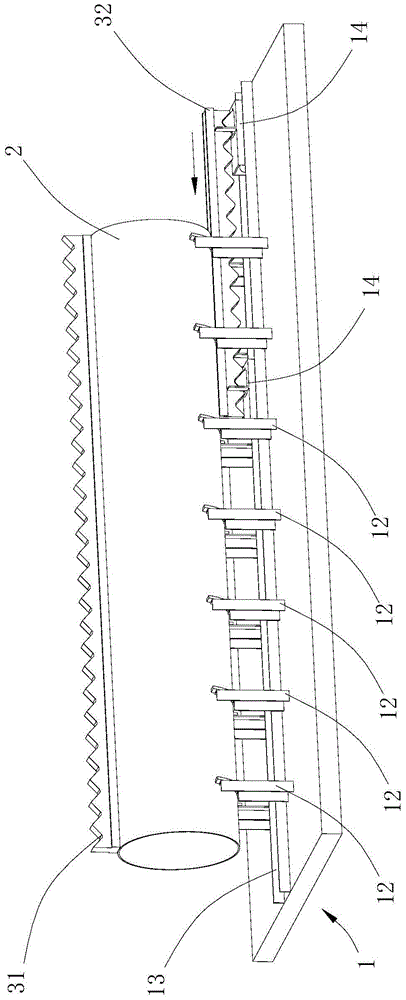

[0023] Implementation of the rack installation device

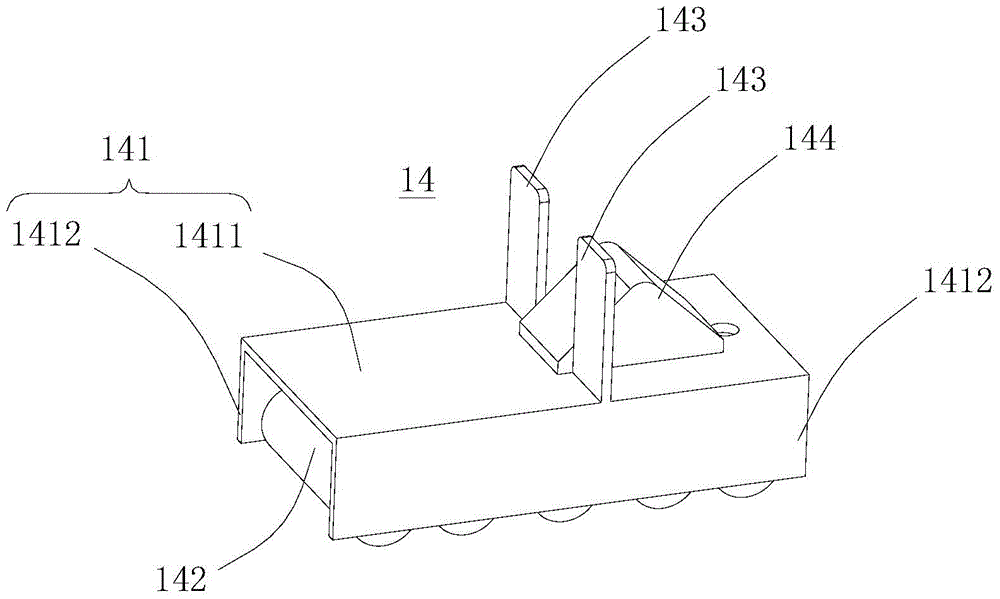

[0024] Such as figure 1 Shown is an embodiment of the rack installation device 1 of the present invention. In this embodiment, the rack installation device 1 mainly includes a base 11 , a plurality of tire frames, a track 13 and two carrying blocks 14 .

[0025] Such as figure 1 As shown, in this embodiment, multiple tire frames are longitudinally arranged on the base 11, and each tire frame includes legs 12 arranged opposite to each other with a certain gap, and multiple gaps ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com