Detection method and detection device for traction of point switch between turnout point rail and stock rail

A basic rail and switch machine technology, applied in the direction of measuring devices, force/torque/power measuring instruments, instruments, etc., can solve problems such as large impact on transportation, inconvenient testing, large traction force, and inability to grasp small changes. Achieve the effects of preventing equipment accidents, accurate and reliable test results, and convenient testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

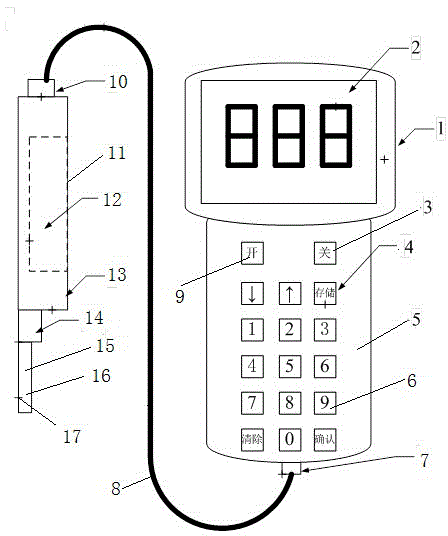

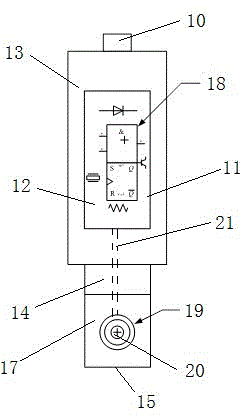

[0030] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

[0031] A method for detecting the traction force of a switch machine between a switch point rail and a basic rail, characterized by:

[0032] A. The first signal maintenance personnel holds the handle of the iron plate, and inserts the 4mm thick test iron plate with the pressure sensor between the tip rail and the basic rail at the first connecting rod of the turnout, and the test surface of the test iron plate is close to the turnout basic Between the rail and the tip rail;

[0033] B. The maintenance personnel of the second signal operate the electric (hydraulic) switch machine, so that the switch machine pushes (pulls) the point rail of the switch to move closer to the basic rail, until the point rail of the switch presses the test iron plate, and the test iron plate is on the turnout. The tip rail and the basic rail are very close, and the 4mm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com