Water-cooling electrode ring protection device for electric arc melting furnace

A technology of water-cooled electrodes and protection devices, which is applied in the field of water-cooled electrode ring protection devices and water-cooled electrode ring protection devices in the smelting process of electric arc furnaces for metallurgy and foundry. It can solve problems such as explosions, achieve direct economic benefits, save funds, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

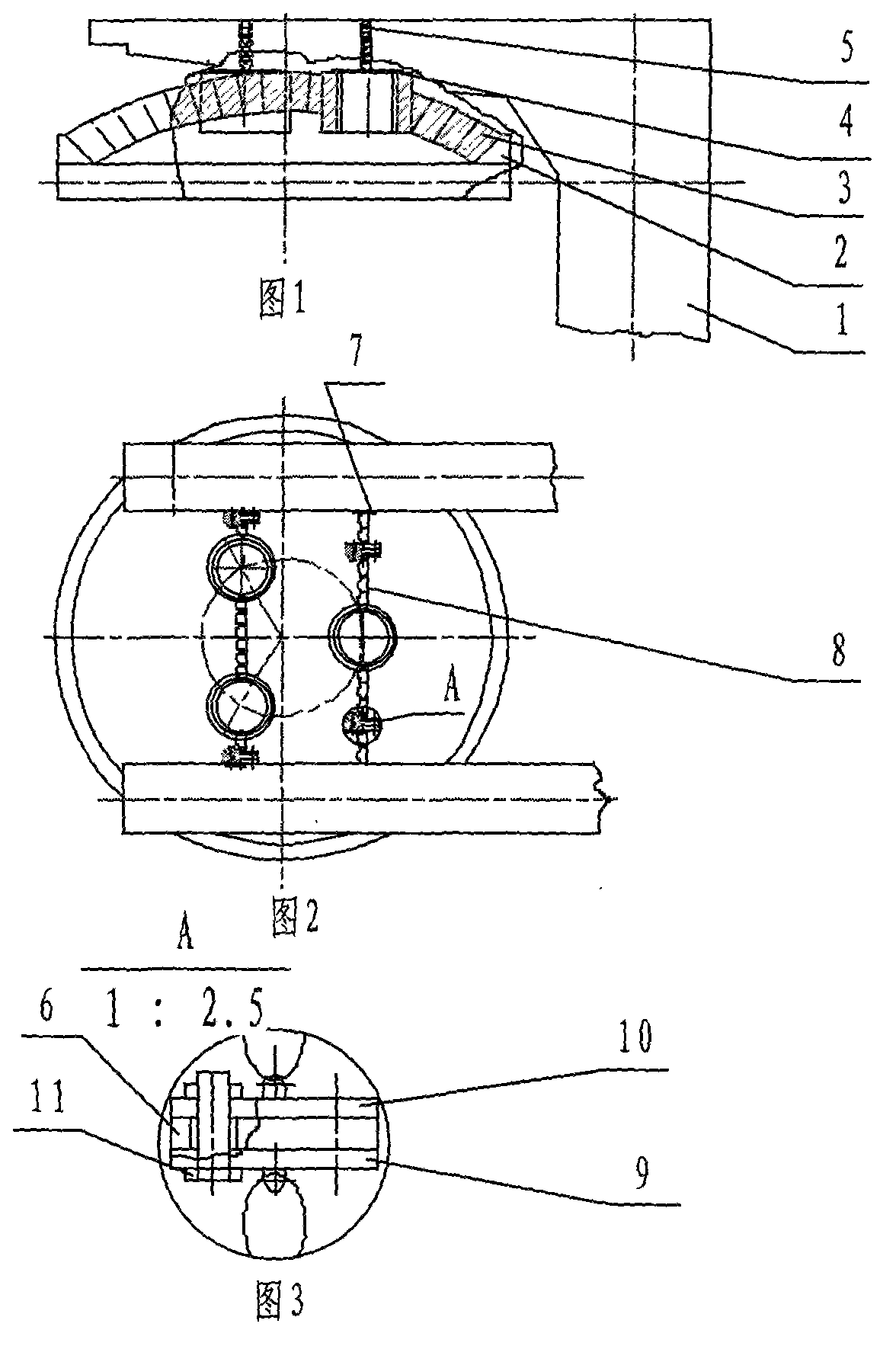

[0013] As shown in the figure: fix the fixed support (7) on the cross arm of the electric arc furnace support arm (1), one end of the safety fastening chain I (5) is connected to the fixed support (7), and the other end is connected to the fixed support (7). The plates II (10) are connected, and the connecting plates I (9) / connecting plates II (10) on both sides of the high-voltage insulator (6) are fastened together with bolts and nuts, and one end of the chain II (8) is securely fastened to the connecting plates I (9) is connected, and the other section is connected to the water-cooled electrode ring (4), so that the electric arc furnace water-cooled electrode ring (4) is connected and fastened with the cross arm part of the electric arc furnace support arm (1), and is used as a brick of the furnace cover. When falling, the water-cooled electrode ring (4) of the electric arc furnace is prevented from falling into the high-temperature molten steel along with the furnace cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com