A banner detection device

A detection device and banner technology, used in conveyor control devices, transportation and packaging, conveyor objects, etc., can solve the problems of high manual inspection intensity, deformation of the frame, stuck in the middle of the frame, etc., to solve the problem of manual inspection intensity Large, avoid the effect of quality accident or equipment accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

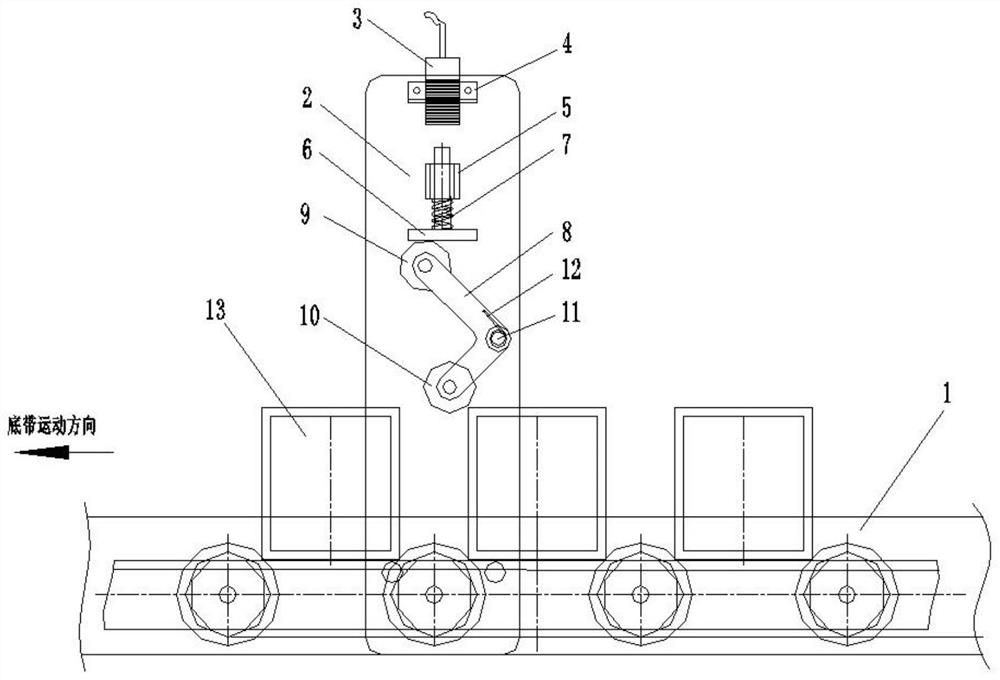

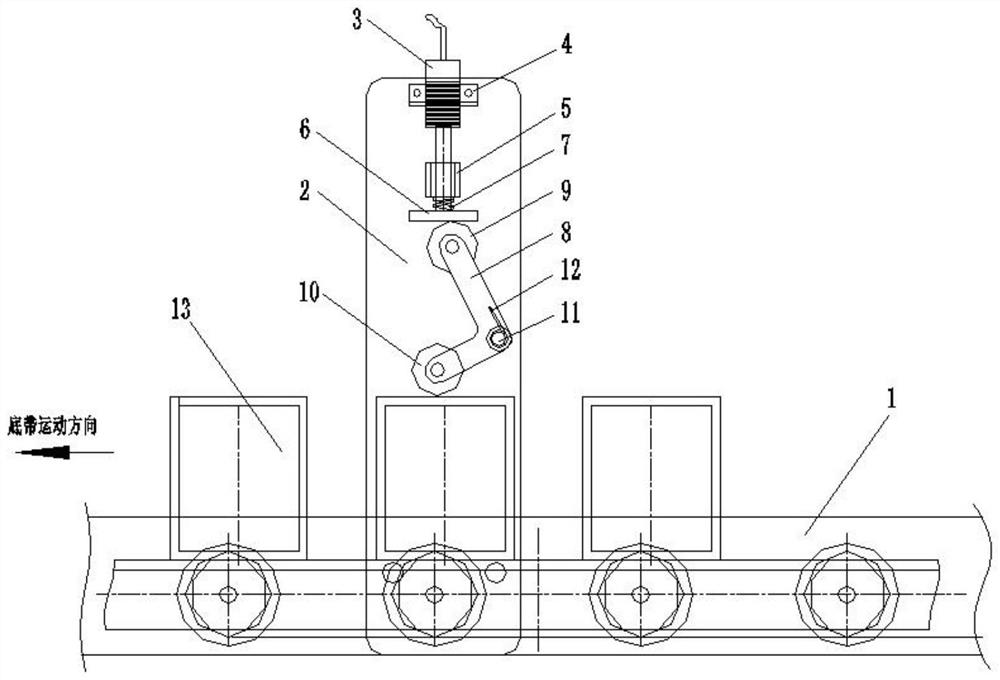

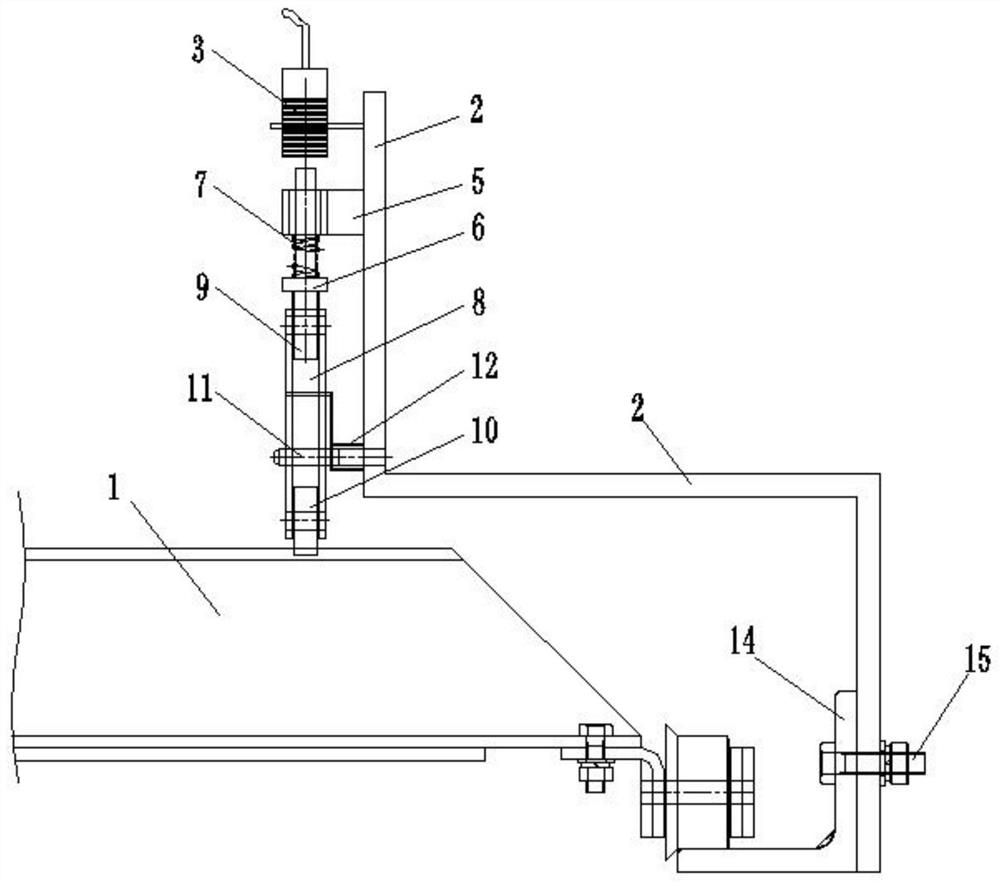

[0021] Such as figure 1 As shown, a banner detection device includes a T-shaped guide rod 6, a controller, a bracket 2 installed on the side of the storage cabinet chain, a proximity switch 3 arranged at the top of the bracket 2, and a positive switch 3 arranged on the proximity switch 3. The fixed seat 5 below, after the spring 7 is sleeved on the T-shaped guide rod 6, passes through the fixed seat 5 from bottom to top, and can move up and down in the fixed seat 5. The T-shaped guide rod 6 The bottom is provided with a pushing device that can periodically push the bottom of the T-shaped guide rod 6 with the movement of the banner 13, and the pushing device can make the top of the T-shaped guide rod 6 touch the proximity switch 3 , thereby triggering the corresponding signal, the controller receives and processes the signal of the proximity switch 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com