A soft package lithium battery packaging device

A soft-pack lithium battery and packaging device technology, which is applied in the manufacture of lithium batteries, non-aqueous electrolyte batteries, and electrolyte batteries, can solve the problems of manpower consumption, increased production costs, and low structural efficiency, so as to reduce production costs and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are preferred embodiments of the present invention.

[0024] Example.

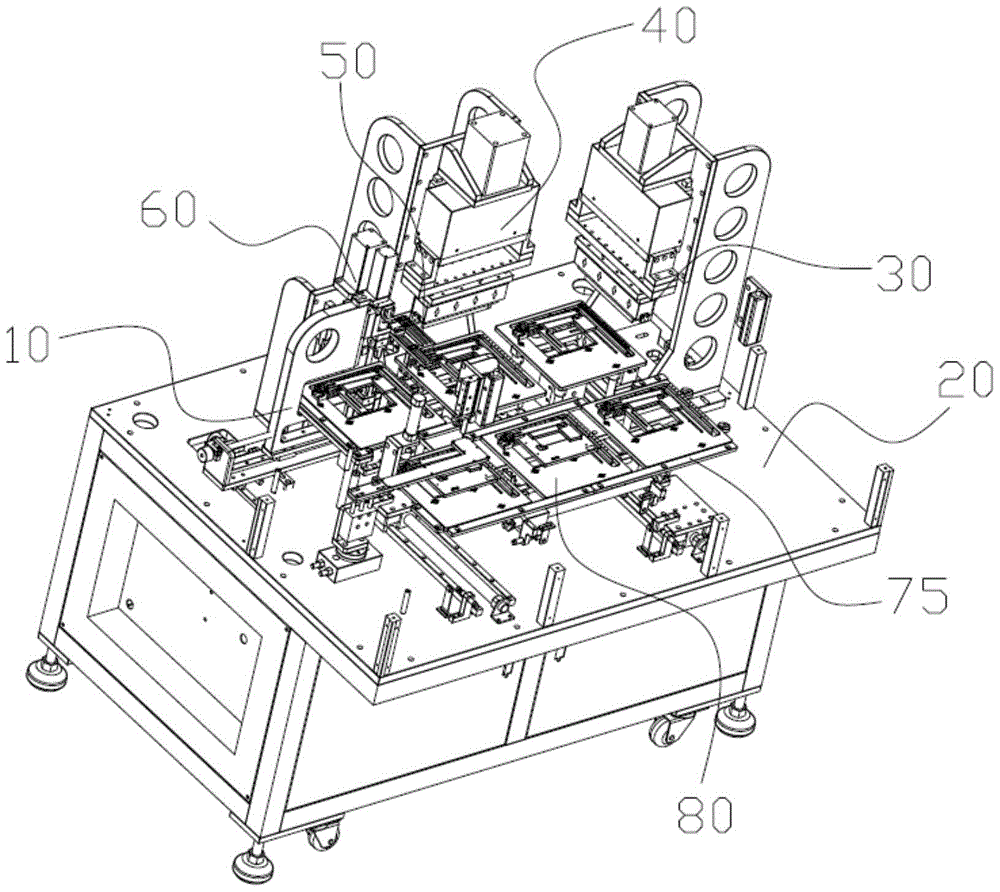

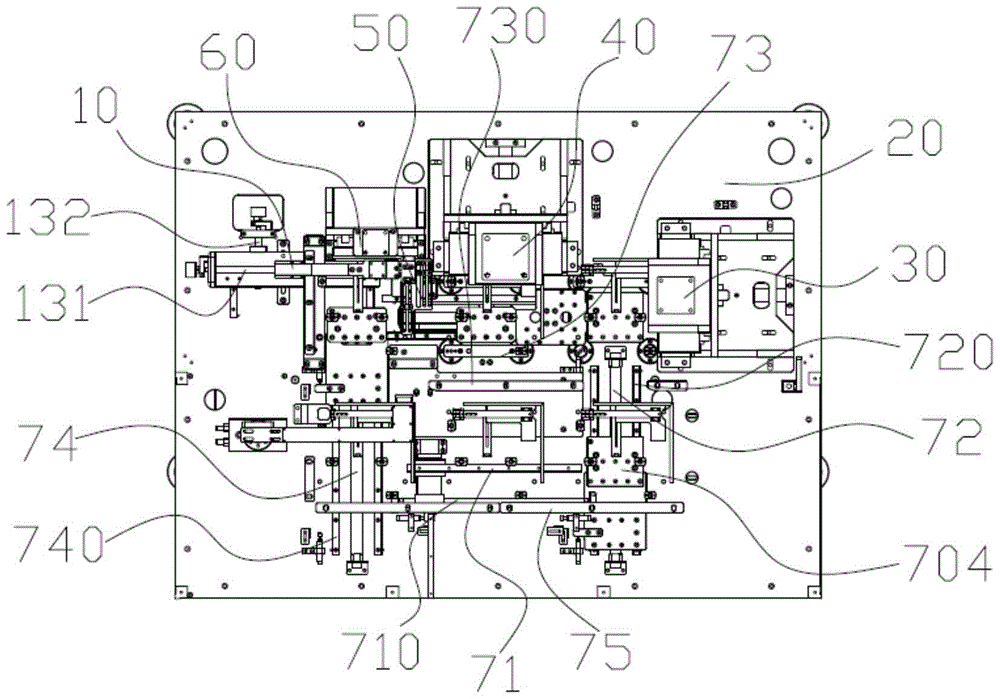

[0025] Such as figure 1 , figure 2 As shown, a kind of soft package lithium battery packaging device of the present invention comprises:

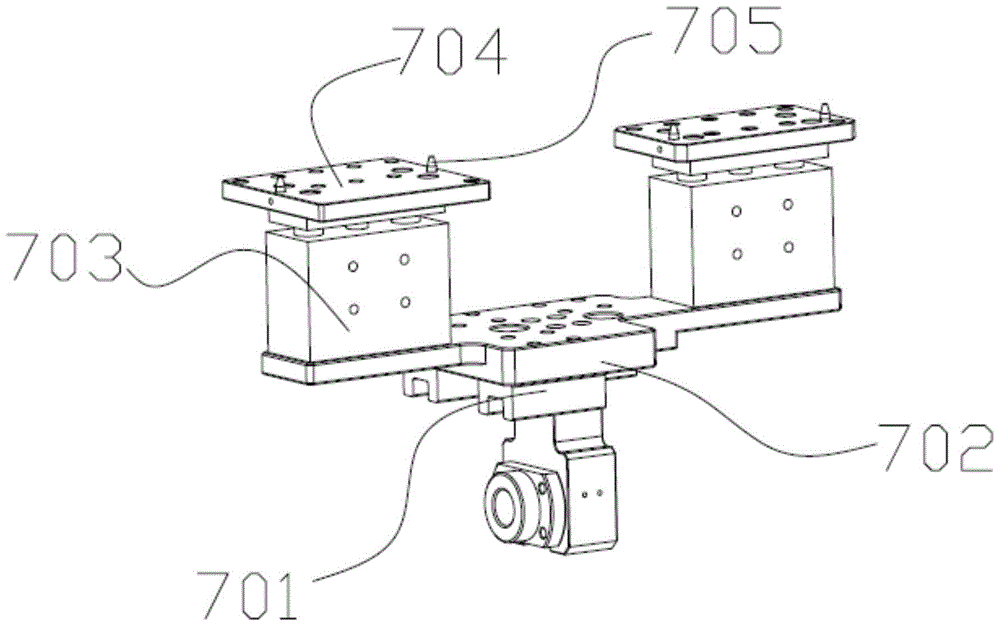

[0026] The workbench 20 is provided with a first transverse mechanism 71, a first longitudinal mechanism 72, a second transverse mechanism 73 and a second longitudinal mechanism 74, the first transverse mechanism 71, the first longitudinal mechanism 72, The second transverse mechanism 73 and the second longitudinal mechanism 74 are connected end to end in sequence and form a "mouth" connection, and the sides of the first transverse mechanism 71, the first longitudinal mechanism 72, the second transverse mechanism 73 and the second longitudinal mechanism 74 are sequentially A top sealing mechanism 30, a side sealing mechanism 40, a detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com