Coil forming apparatus and method

一种线圈、线圈板的技术,应用在线圈形成装置以及领域,能够解决昂贵、系统复杂等问题,达到易于操作和控制、实施方式便宜的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The components described below as constituting the respective embodiments are intended to be illustrative and not restrictive. Many suitable components and materials described herein that can perform the same or a similar function are intended to be within the scope of embodiments of the invention.

[0019] Embodiments of the present invention will now be described in detail with reference to the accompanying drawings, in which like reference numerals refer to like parts.

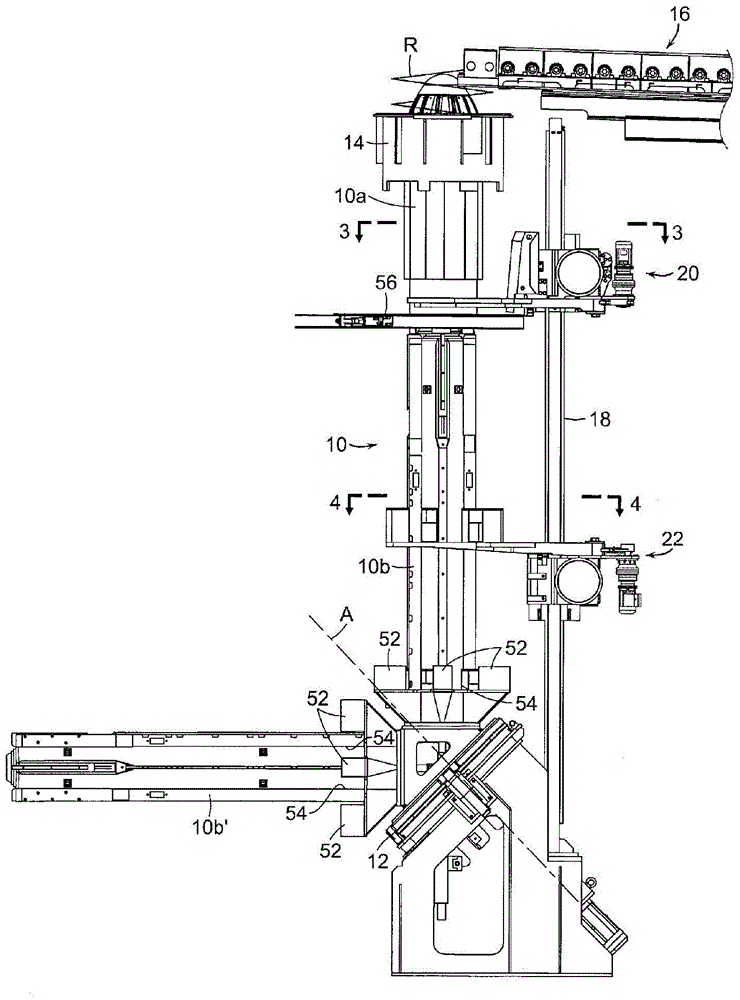

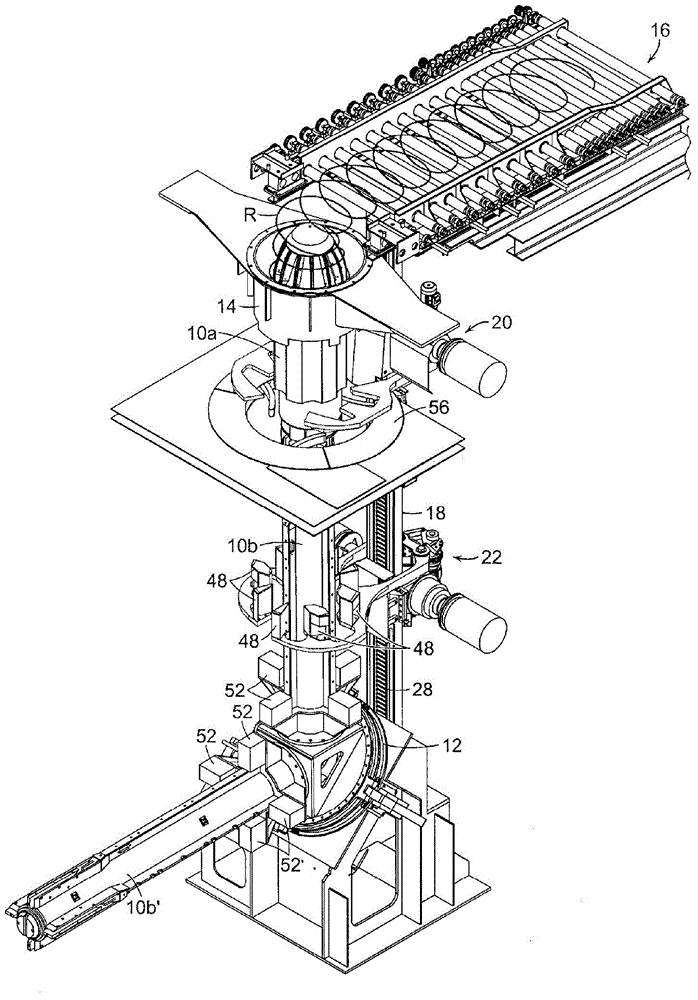

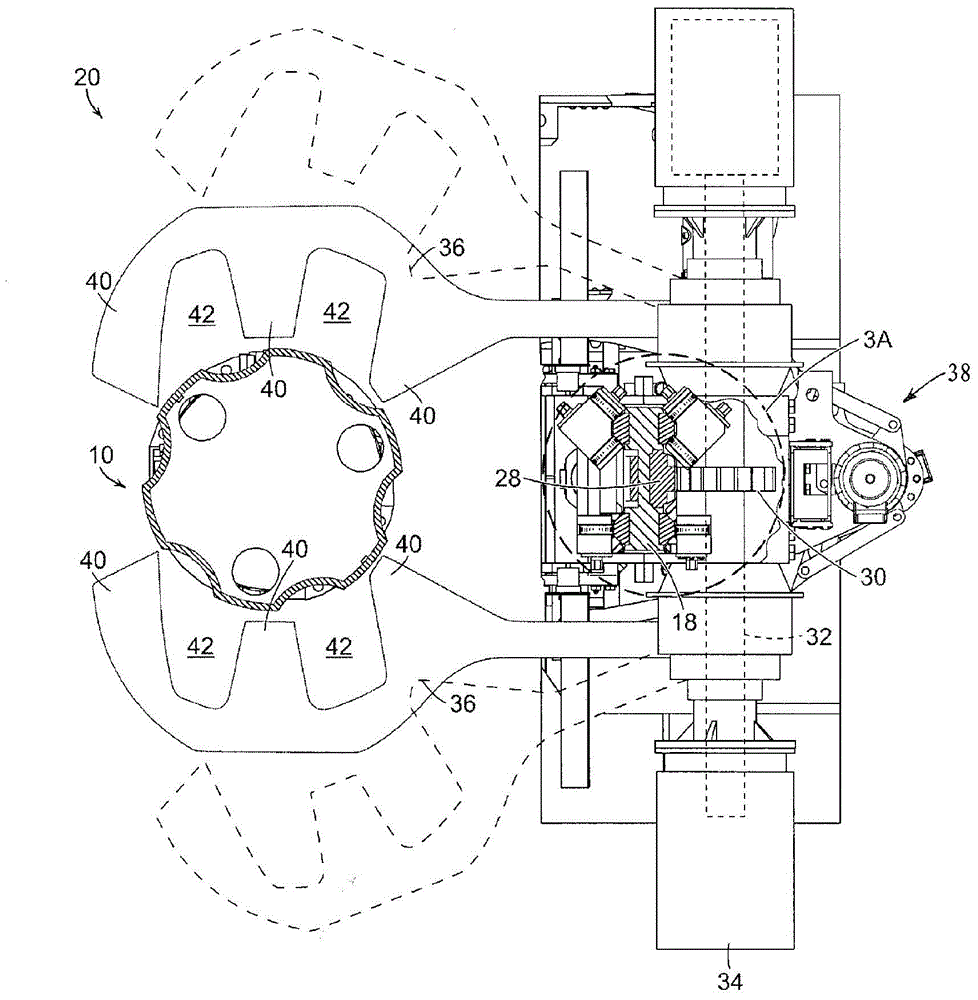

[0020] First refer to figure 1 and figure 2 , a device according to an exemplary embodiment of the invention is shown comprising a vertically arranged mandrel 10 having an upper end 10a (commonly referred to as a "nose cone") detachable from a bottom bar 10b. The mandrel rod 10b and the counter-mandrel rod 10b' are arranged on the base 12 orthogonally. The base is rotatable about axis "A".

[0021] The upper end 10a of the mandrel 10 protrudes upwards into the reforming chamber 14 and is po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com