A dust jacket iron positioning device

A technology of positioning device and dust cover, which is applied in the direction of positioning device, feeding device, storage device, etc., and can solve the problems that iron parts are easy to run away from the original position and products are scrapped.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

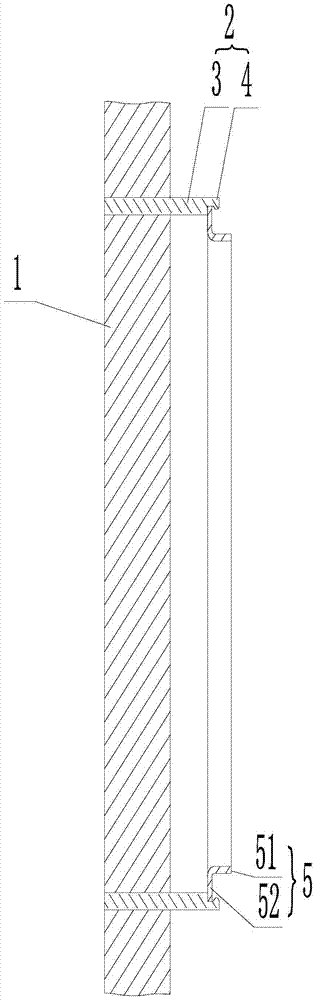

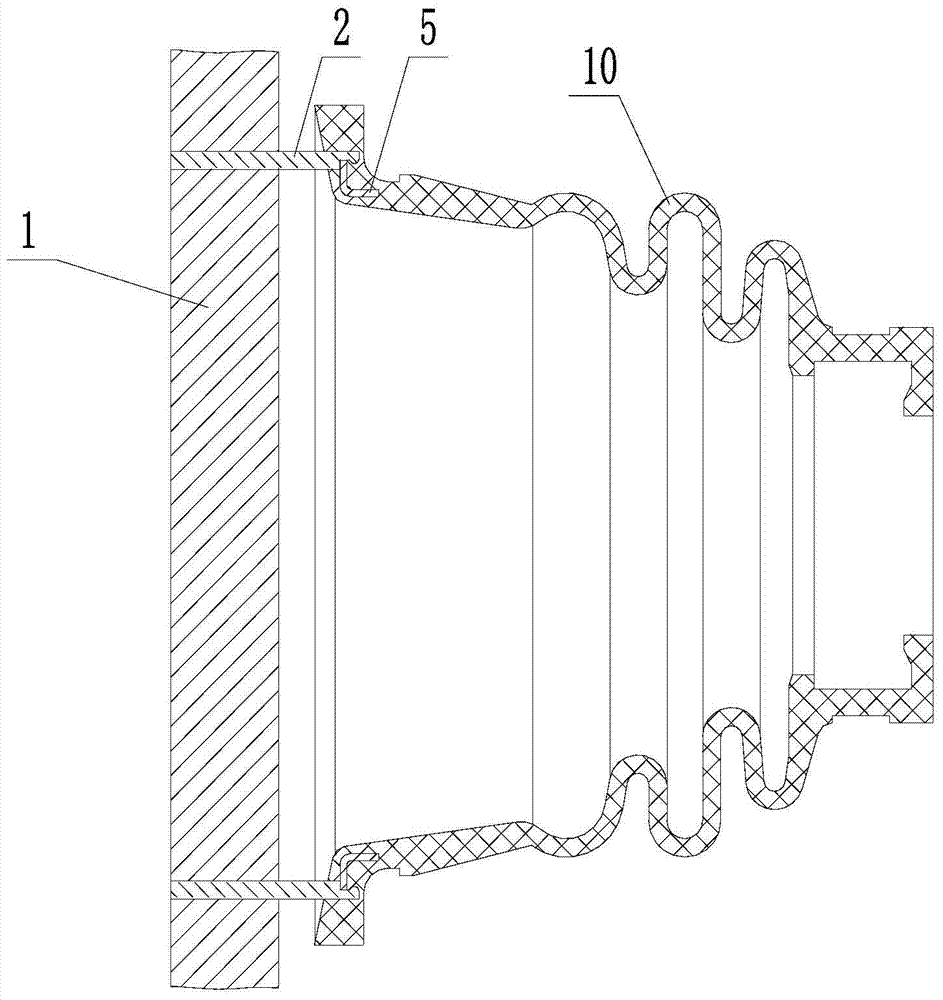

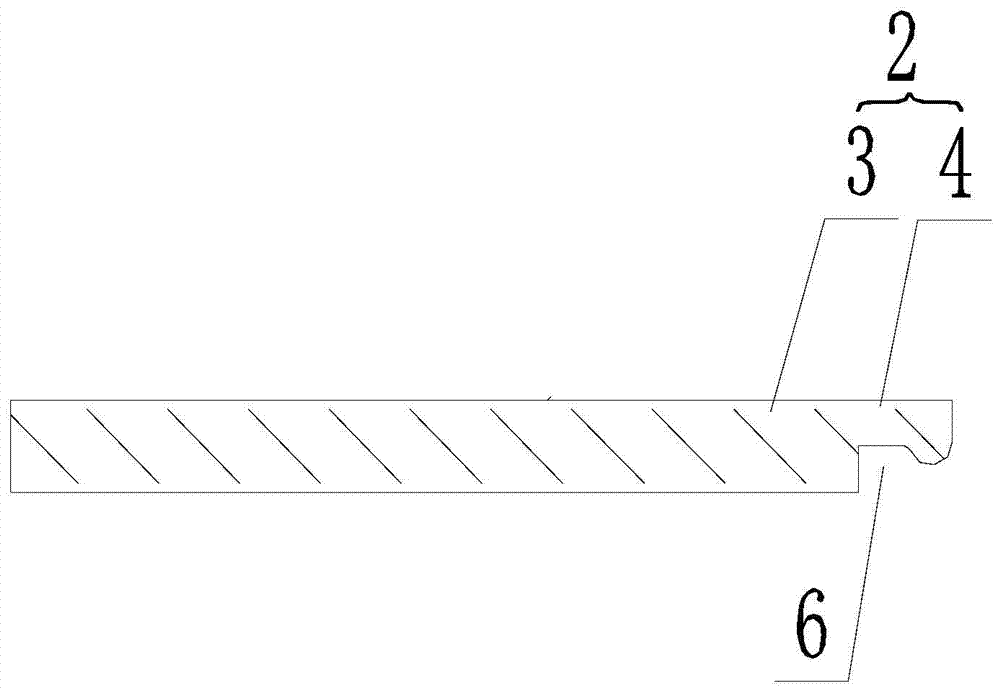

[0018] refer to figure 1 , figure 2 and image 3 , a dust-proof jacket iron parts positioning device, the dust-proof jacket iron parts 5 are composed of a round tube 51 and a convex eaves 52 surrounding one end of the outer wall of the round tube 51, including a vulcanization mold 1, four fixedly connected on the vulcanization mold 1 And the elastic hooks 2 evenly distributed on the same circumference, each elastic hook 2 is composed of a support rod 3 fixedly connected to the vulcanization mold 1, and an elastic pull hook 4 arranged on the support rod 3. A slot 6 for clamping the protruding eaves 52 is provided. The drag hook 4 is integrally arranged with the pole 3 .

[0019] The elastic hook 2 is made of spring steel. The bottom surface of the slot 6 is an arc-shaped surface matched with the protruding eaves 52 . Dustproof cover iron part 5 is set in the dustproof cover 10.

[0020] During installation, the four elastic hooks 2 are bent, and the dust-proof jacket iro...

Embodiment 2

[0022] refer to Figure 4 and Figure 5 , the difference from the first embodiment is that the pull hook 4 is detachably arranged on the pole 3 . The drag hook 4 is cylindrical, and the side wall of the drag hook 4 is provided with a slider 9; the inside of the pole 3 is provided with a blind hole 7 matched with the drag hook 4, and the inner wall of the blind hole 7 is provided with a slider 9 The matching chute 8, the chute 8 is composed of a straight groove 81 parallel to the axis of the blind hole 7 and having an outer end for the slider 9 to enter, and an arc-shaped groove 82 communicating with the straight groove 81 and used to lock the slider 9 constitute. The outer end of the straight groove 81 communicates with the outside, and the arc groove 82 is arranged in the circumferential direction of the blind hole 7;

[0023] The slider 9 on the side wall of the hook 4 reaches the bottom of the blind hole 7 along the straight groove 81, and the hook 4 is inserted into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com