Continuous Felt Rolling Machine

A felt rolling machine and core technology, which is applied in the direction of winding strips, thin material processing, transportation and packaging, can solve the problems of high manufacturing cost, high energy consumption, and increase the production cost of coiled materials, and can reduce energy consumption. The effect of reducing consumption and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with accompanying drawing and embodiment:

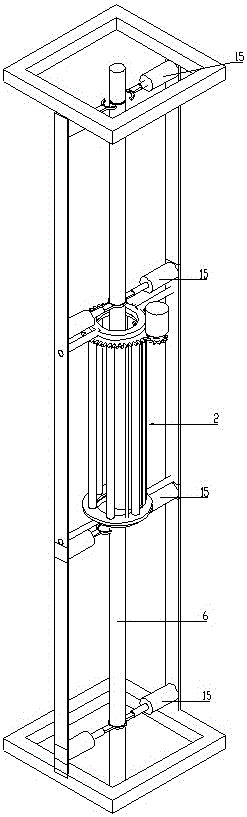

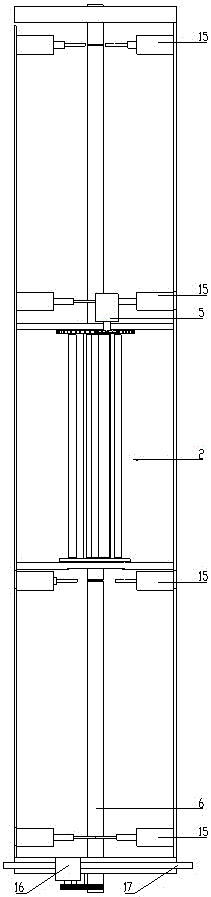

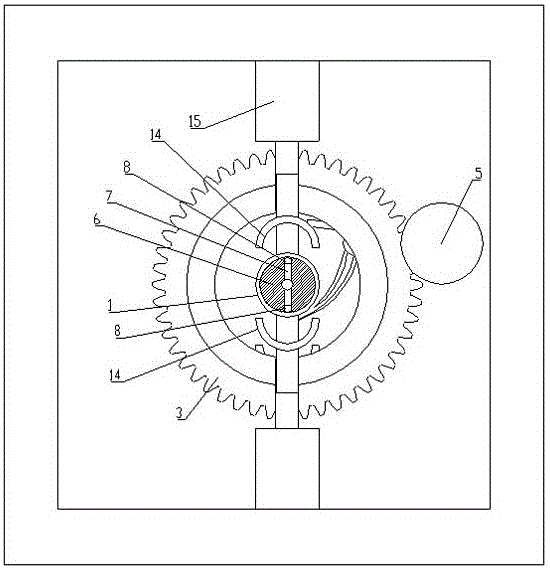

[0020] Such as Figures 1 to 4 Shown: The continuous felt rolling machine in this embodiment includes a winding core 1, an outer layer rolling device and an inner layer rolling device, and the inner layer rolling device includes an axially passing through the middle of the frame The polished rod 6 and the driving mechanism that drives the polished rod 6 to rotate, such as a motor and a reducer, the polished rod 6 is provided with a radially extending hole 7, and the hole 7 is provided with a support pin 8 that is slidably matched with the hole. The core 1 can be sleeved on the polished rod 6, and the support pin 8 is used to fix the core to prevent relative rotation between the core and the polished rod; the outer layer rolling device includes a prismatic frame 2 and a driving device A frame driving device for the rotation of the prismatic frame 2, the fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com