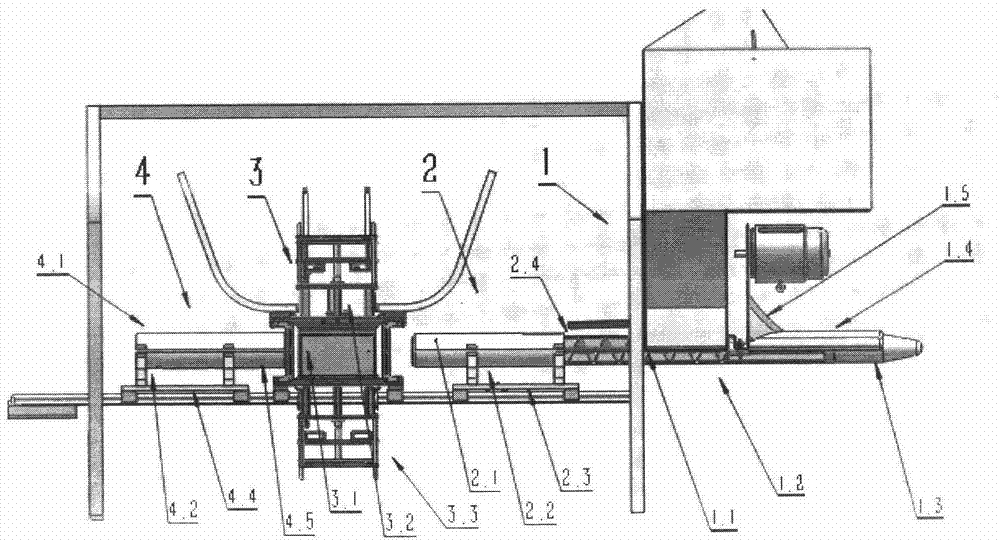

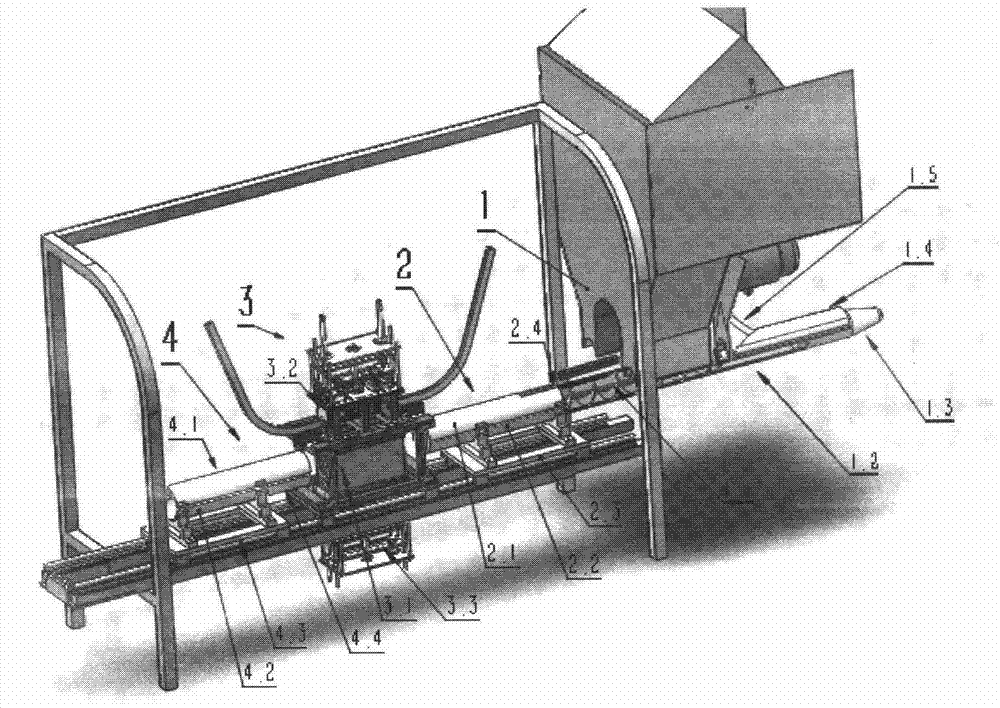

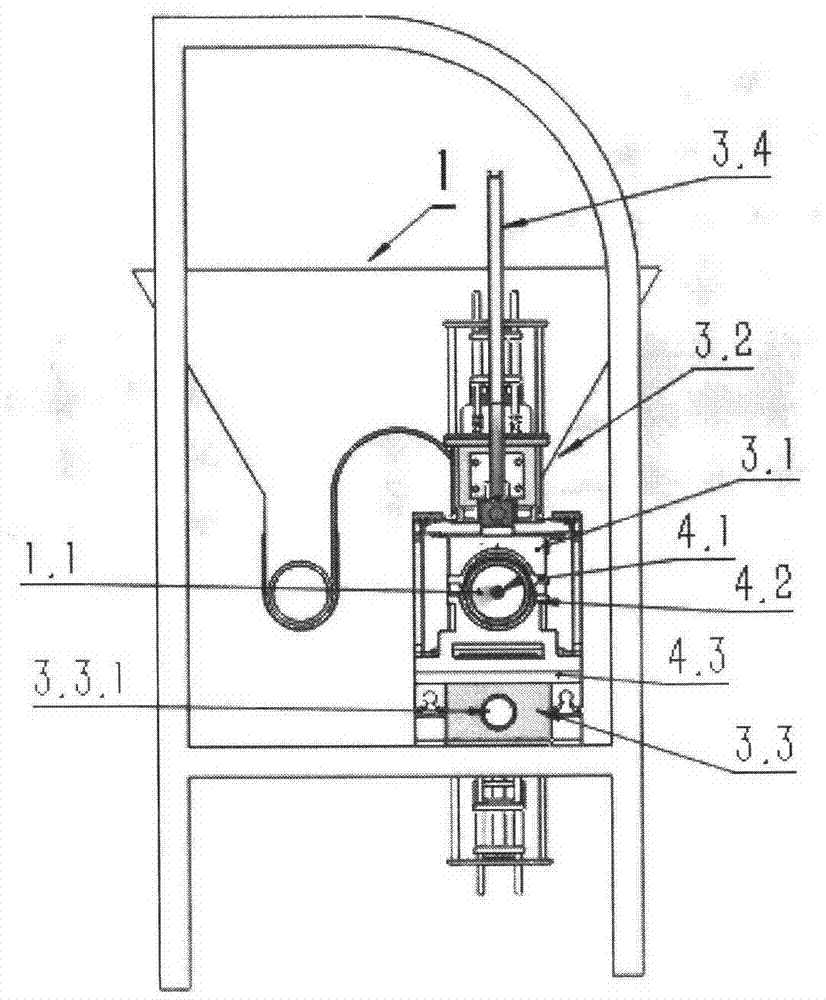

Full-automatic fungus manufacturing machine

A technology of sports board and plastic film, which is applied in the fields of horticulture, application, and botany equipment and methods, can solve the problems such as the inability to realize continuous production, and achieve the effect of continuous production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] 1.1 Filling and heat sealing mechanism;

[0083] The medium enters the entrance of (1.1) "screw" and (1.2) "screw tube" from the supply hopper, and at this time, the circular barrel or strip-shaped plastic film is conveyed from (1.3) "plastic film guide tube" and (1.4) The front end of "plastic film guide tightening part" enters, passes through (1.2) "screw tube" periphery, to (1.5) "plastic film incision knife" (circular barrel-shaped plastic film is promptly cut). Run smoothly until (2.1) "semi-circular pipe A" (2.2) "semi-circular pipe B" passes through, and at the same time at 2.4 "plastic film stacking and heat sealing place", the plastic film has been superimposed and heat-sealed into a drum shape. In the middle (1.1) the "screw" continuously transports the medium, fills it into the middle of the bonded round film bag, and forms a round cylinder. Completed the first process: filling and heat sealing.

[0084] 2.2 Quantitative and fixed shape;

[0085] (2.1) "Se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com