Raw hemp continuous and automatic slivering process and continuous slivering production line

A production line and automatic technology, applied in textiles and papermaking, mechanical processing, fiber mechanical separation, etc., can solve the problems of high work intensity, harsh working environment, and low work efficiency, so as to improve the uniformity of dryness and reduce the workload of workers , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] DRAWINGS Specific embodiments and further detailed description of the present invention;

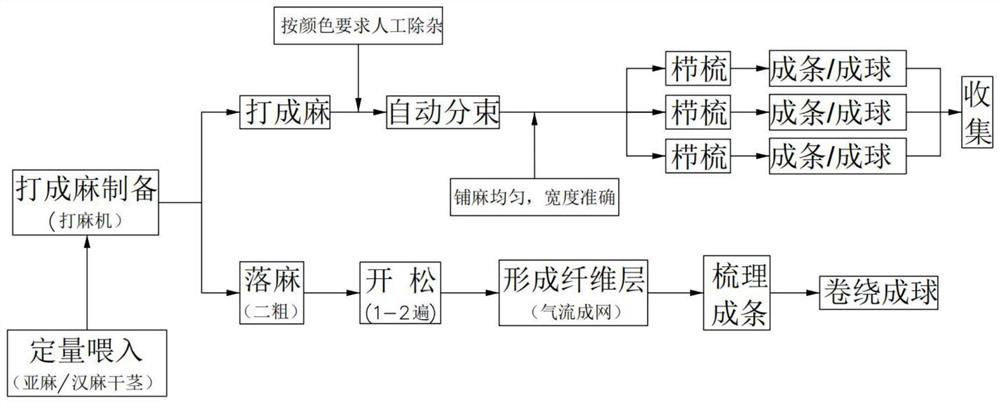

[0042] like figure 1 As shown in a continuous automatic raw jute strips process, comprising the steps of:

[0043] One, labeled Ma preparation:

[0044] (1), or flax stems by Han Asahara selected from the stem, bale, retting, drying, and other health treatment step to obtain dry flax or hemp stalks;

[0045] (2), the stems of flax or hemp artificially or mechanically fed quantitative scutching machines, flax or hemp stalk shredding stems of sequentially processed and scutching process, to obtain labeled flax or hemp and linen noil; scutching machine to the type B-800 scutching Association engine, 6BY-870 type joint scutching machine or other single or double stem broken scutching Association engine.

[0046] Second, automatic beam:

[0047] (3), flax scutching machine to obtain the labeled flax or hemp mechanically automatic beam treatment, flax hemp or hemp labeled in accordance with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com