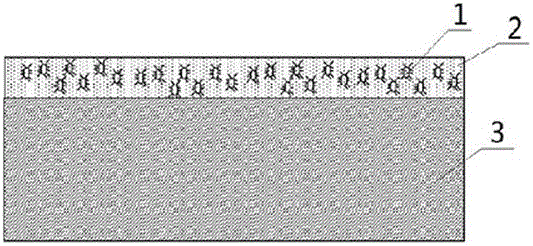

Phase change microcapsule self-regulating grc dry powder mortar surface layer material

A phase change microcapsule and dry powder mortar technology, which is applied in the field of dry powder mortar for construction, can solve the problems of affecting the mechanical properties and durability of GRC materials, being easy to break, and the effect of phase change capsule temperature regulation, etc., so as to avoid the problem of rupture and improve the Thermal conductivity, good effect of automatic temperature adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0033] (1) Put the commercially available phase-change microcapsules with a mass percentage of 77% into a vibrating mixer, spray water with a mass fraction of 5% under the condition of vibrating and stirring, so that the surface of the phase-change microcapsules is thoroughly wetted, and then add The mass fraction is 15% white cement and 3% carbon fiber, so that the surface of the phase change microcapsules is covered with a layer of white cement mixed with carbon fiber, shake and stir continuously at 25 °C for 24 hours, and dry at 50 °C to obtain the modified phase change microcapsules. capsule.

[0034] (2) Mix 35% white cement, 40% quartz sand, 1% redispersible latex powder, 0.5% powder polycarboxylate superplasticizer, 8% fly ash, 0.5% cellulose ether, 2% high dispersion Add permanent glass fiber, 2% inorganic toner, and 11% modified phase-change microcapsules into a stirrer and stir evenly to obtain phase-change microcapsule self-regulating GRC dry powder mortar surface m...

Embodiment example 2

[0036] (1) Put the commercially available phase-change microcapsules with a mass percentage of 88.5% into a vibrating mixer, spray water with a mass fraction of 3% under the condition of oscillating and stirring, so that the surface of the phase-change microcapsules is thoroughly wetted, and then add The mass fraction is 8% white cement and 0.5% carbon fiber, so that the surface of the phase change microcapsules is covered with a layer of white cement mixed with carbon fiber, shake and stir continuously at 20°C for 24 hours, and dry at 80°C to obtain the modified phase change microcapsules. capsule.

[0037] (2) Mix 40% white cement, 33% quartz sand, 0.2% redispersible latex powder, 0.1% powder melamine superplasticizer, 3% silica fume, 2% acicular wollastonite, 0.2% cellulose ether , 1.5% polypropylene fiber, 5% inorganic toner, and 15% modified phase-change microcapsules were added to the mixer and stirred evenly to obtain the phase-change microcapsule self-regulating temper...

Embodiment example 3

[0039] (1) Put commercially available phase-change microcapsules with a mass percentage of 80% into a vibrating mixer, and spray water with a mass fraction of 4% under the condition of oscillating and stirring, so that the surface of the phase-change microcapsules is thoroughly wetted, and then add The mass fraction is 14% white cement and 2% carbon fiber, so that the surface of the phase change microcapsules is covered with a layer of white cement mixed with carbon fiber, shake and stir continuously at 28°C for 20h, and dry at 60°C to obtain the modified phase change microcapsules. capsule.

[0040] (2) Mix 25% white cement, 45% quartz sand, 2% redispersible latex powder, 2% powder melamine superplasticizer, 5% silica fume, 2% wollastonite, 0.1% cellulose ether, Add 0.9% carbon fiber, 4% inorganic toner, and 14% modified phase-change microcapsules into the mixer and stir evenly to obtain the phase-change microcapsule self-regulating GRC dry powder mortar surface material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com