Over-temperature protection method, circuit and linear drive circuit with the circuit

An over-temperature protection circuit and over-temperature protection technology, applied in the field of electronics, can solve the problems of cumbersome operation, inaccurate temperature detection, inability to realize self-starting of power tubes, etc., and achieve the effect of timely protection and reducing inherent errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

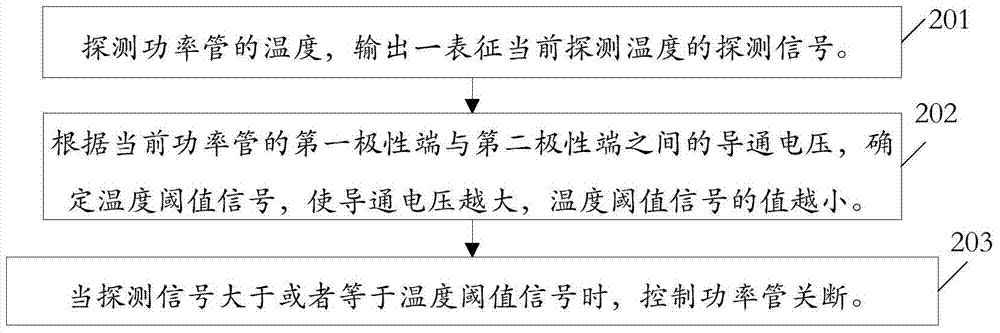

[0054] figure 2 For a schematic flow chart of a power tube over-temperature protection method provided in this embodiment, see figure 2 As shown, the method mainly includes the following steps:

[0055] Step 201: Detect the temperature of the power tube, and output a detection signal representing the currently detected temperature.

[0056] In this embodiment, the temperature of the power tube is detected to obtain a detection temperature (denoted as T sens ), and according to the detection temperature T sens Output one represents the current detection temperature T sens The probe signal S temp , so that the detection temperature T sens The higher the corresponding detection signal S temp higher.

[0057] As an illustration of this embodiment, the temperature of the power tube can be detected by the temperature sensing unit, and the detected temperature T sens The probe signal S temp It can be a voltage signal, that is, the temperature detected by the sensor in the ...

Embodiment 2

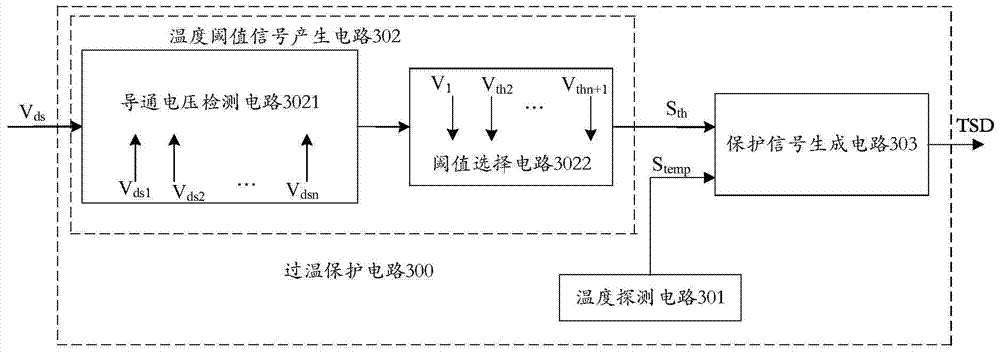

[0077] image 3 , 4 For the schematic diagram of the circuit principle of a power tube over-temperature protection circuit provided in Embodiment 1, see image 3 As shown, it mainly includes: a temperature detection circuit 301 , a temperature threshold signal generation circuit 302 and a protection signal generation circuit 303 . Its connection relationship and working principle are as follows:

[0078] Wherein, the temperature detecting circuit 301 detects the temperature of the power tube, and outputs a signal representing the detected temperature T sens The probe signal S temp . As an illustration of this embodiment, the temperature detection circuit 301 may include a temperature sensing unit to detect the temperature of the protected power tube.

[0079] The temperature threshold signal generating circuit 302 is based on the conduction voltage V between the first polarity terminal and the second polarity terminal of the power tube ds , the output temperature thresho...

Embodiment 3

[0099] In this embodiment, the Figure 5 The power tube over-temperature protection circuit 300 is used as an example in the linear drive circuit shown, and the implementation of the power tube over-temperature protection circuit is further described.

[0100] see Figure 5 As shown, the linear drive circuit of this embodiment mainly includes a main power stage circuit, and the main power stage circuit includes a power transistor M5 and an over-temperature protection circuit 300 disposed in the main power circuit.

[0101] see Figure 5 As shown, the first polarity terminal of the power tube M5 is coupled to the DC voltage input terminal Vout of the linear drive circuit through the load, and the second polarity terminal is coupled to the ground terminal through the detection resistor Rs, so that the first polarity of the power tube M5 flows through the power tube M5. The currents at the polarity terminal and the second polarity terminal are output currents of the linear driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com