Rotavator with gear exchange unit

A technology of exchange device and rotary tiller, applied in the direction of gear transmission device, transmission device, belt/chain/gear, etc., can solve the problems of unresolved, unresolved soil state, addition and subtraction of power, etc., to improve the convenience of parts storage performance, improve work adaptability, and effectively cultivate the effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0023] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings. Moreover, in the description of the present invention, when detailed descriptions of related well-known functions or structures may unnecessarily obscure the gist of the present invention, detailed descriptions thereof will be omitted.

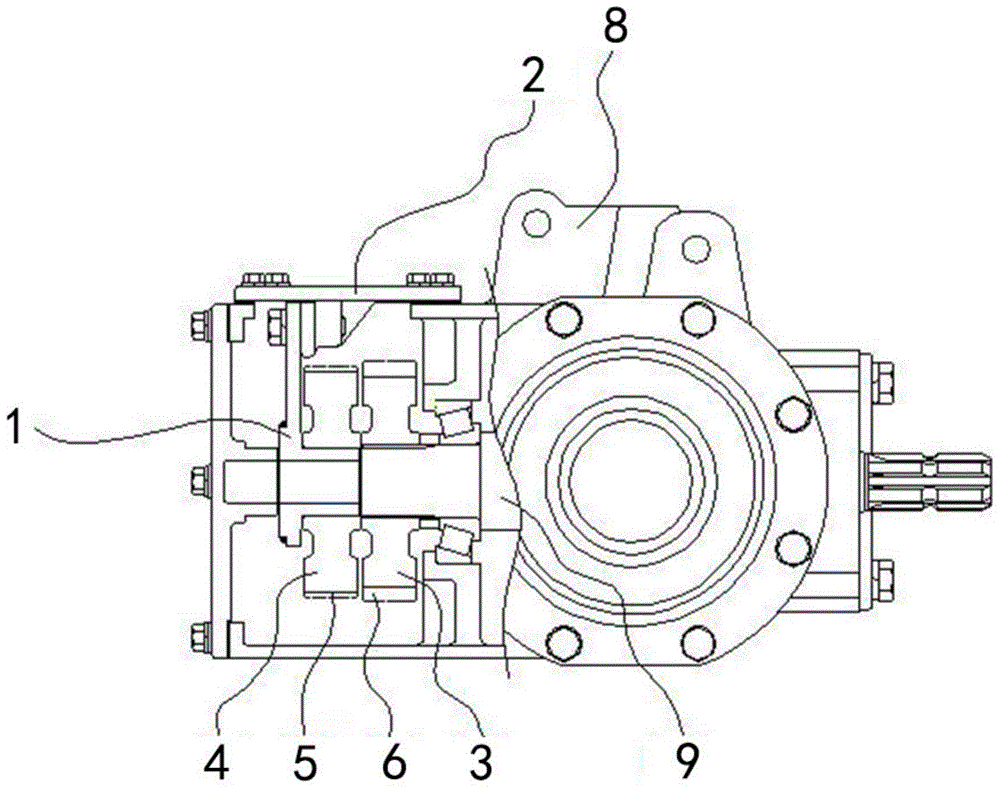

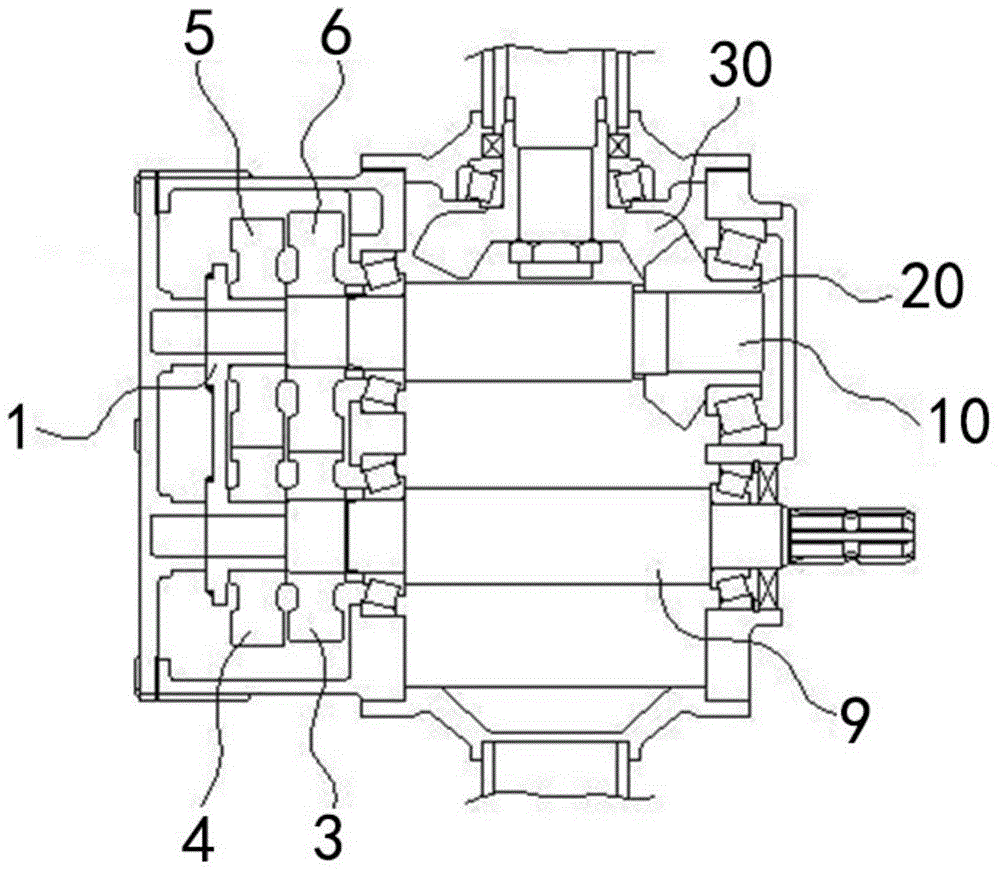

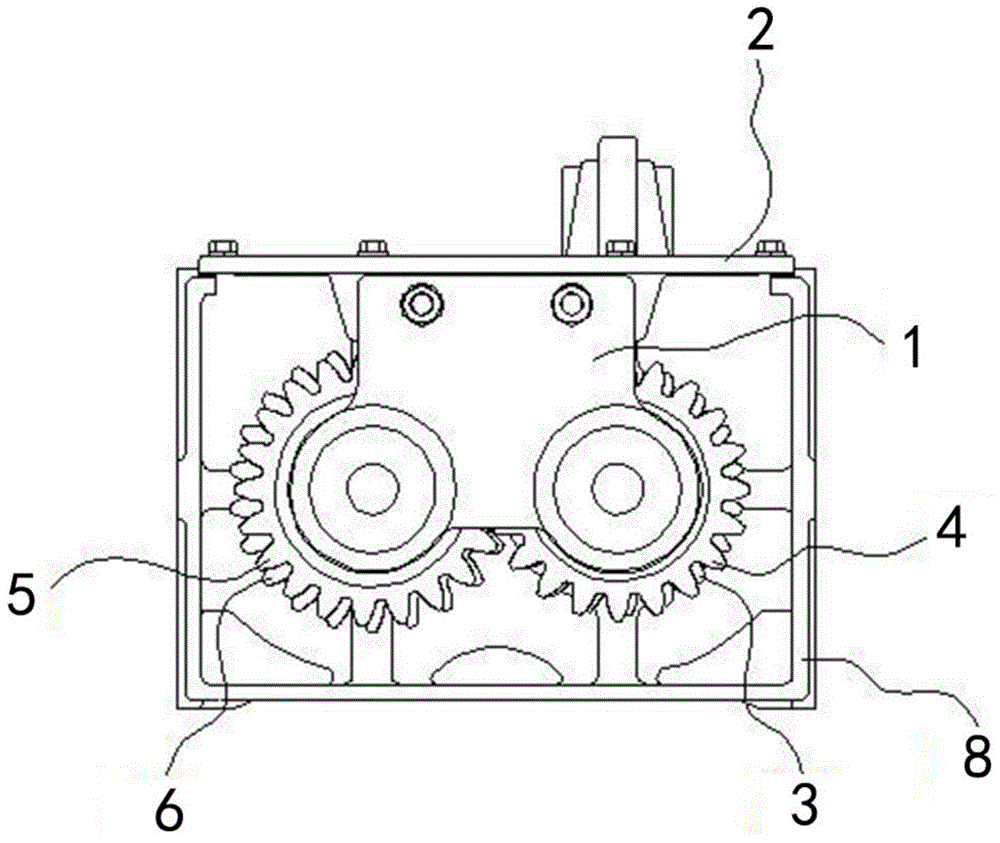

[0024] Figure 1 to Figure 5 The rotary cultivator with a gear exchange device of the present invention shown includes a PTO shaft 9 that outputs the power of the tractor, and receives power through the connection of the input shaft 10 and the PTO shaft 9. The rotary cultivator is characterized in that: The PTO shaft 9 and the input shaft 10 are arranged in parallel in the gear box 8. The PTO shaft 9 is equipped with a first conversion gear 3, and the input shaft 10 is equipped with a first driven gear 6, two The second gear 4 is mounted on the side of the first gear 3, and the second gear 5 is mounted on the side of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap