An automatic mixing and adjusting feeding system for aquaculture feed

A technology of mixed adjustment and aquaculture, which is applied in the fields of fish farming, application, climate change adaptation, etc., can solve the problems of inaccuracy, unevenness, labor consumption, etc., and achieve the improvement of uniformity of feeding, high degree of automation, and feeding capacity strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

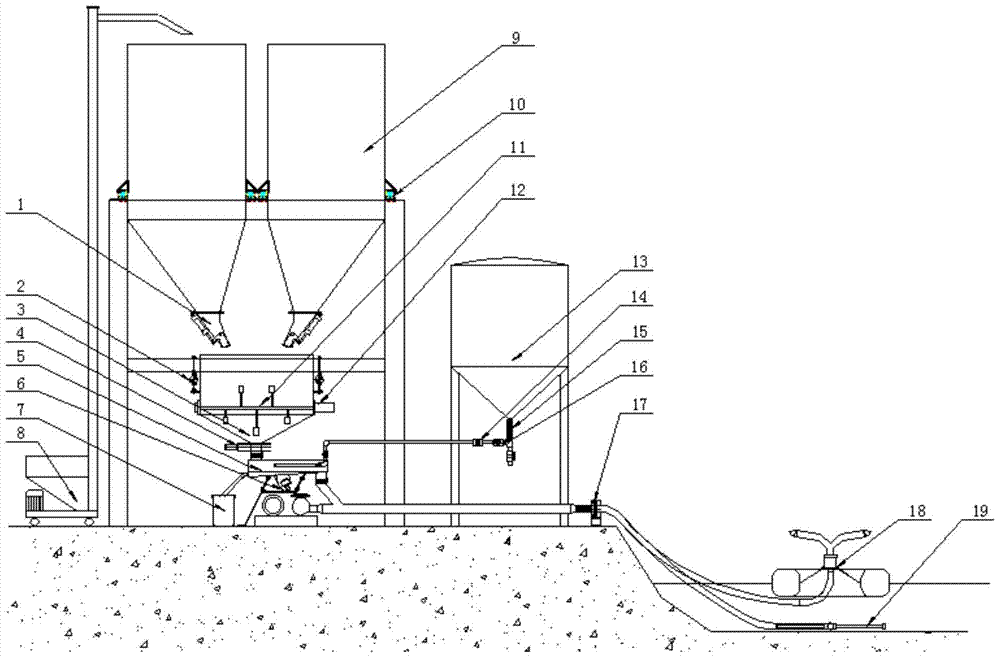

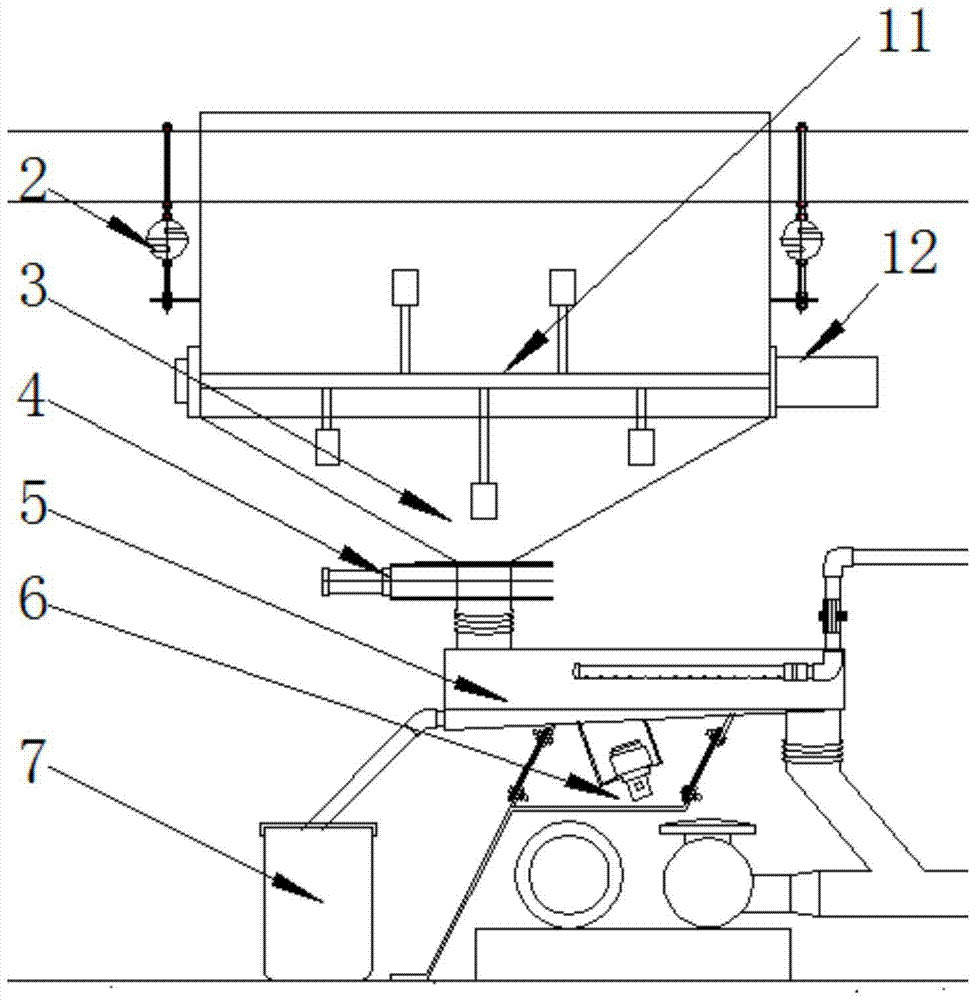

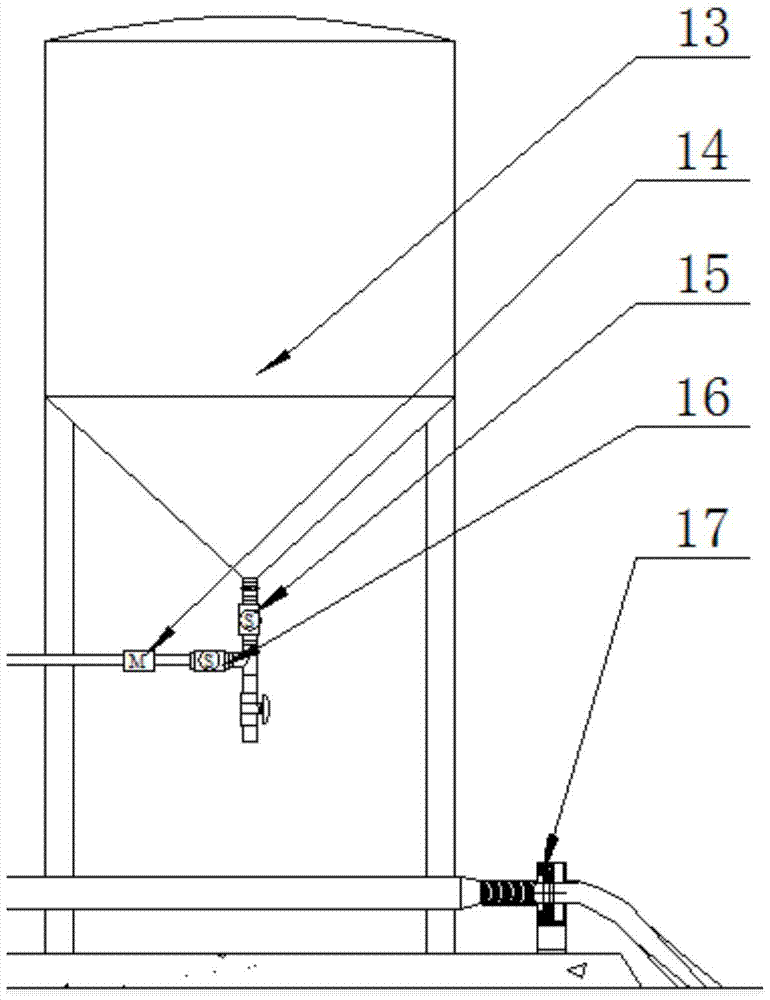

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0034] see Figure 1-Figure 3 , an aquaculture feed automatic mixing and adjusting feeding system, in the group of standardized aquaculture ponds, a plurality of adjacent ponds are correspondingly provided with a feed feeding station, and the feed feeding station includes a combination feed bin 9, a feed bin 3, a mobile Loading machine 8, bacteria liquid adding mechanism; the combined silo 9 is provided with a silo weighing module 10, and the silo weighing module 10 automatically feeds back and controls the weight of the feeding material and the weight of the unloading material; the bottom of the combined silo 8 A pneumatic valve 1 is provided, and the pneumatic valve 1 is aligned with the batching bin 3 below. 5 is provided with a vibrating feeder 6, and the vibrating feeder 6 filters the powdered feed into the powder collection tube 7; the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com