Heating tube with descaling device

A heating tube and electric heating tube technology, applied in the field of heating tubes, can solve the problems of difficulty in cleaning, no dirt, short service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

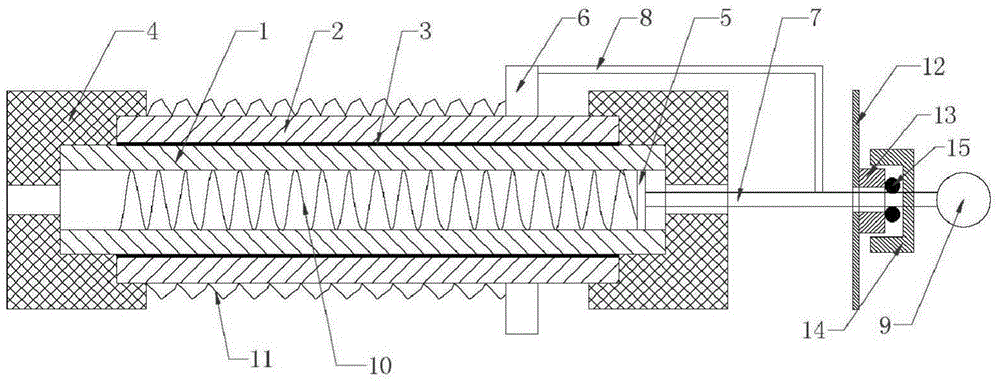

[0020] Such as figure 1 As shown, the electric pipe with descaling device of the present invention includes a pipe body 1, and a heating element 3 is arranged outside the pipe body 1, and the heating element 3 is an external burner or electrothermal coating; said pipe body 1 is a No. 1 glass tube, No. 1 glass tube and the electrothermal coating on the outside of No. 1 glass tube 1 form the main body of the electrothermal tube. An internal scraper 5 is placed in the inner cavity of the tube body 1. The internal scraper 5 is a hollow scraper. 5 is driven by a reciprocating driving part to move along a straight line, and the lower end of the internal scraper 5 is fixedly connected with an internal descaling spring 10 whose outer diameter is compatible with the inner cavity of the tube body 1; the main body of the electric heating tube is installed in a housing 12 Inside, a guide block 13 with external thread is fixedly installed on the outer wall of the housing 12, and a nut 14 i...

Embodiment 2

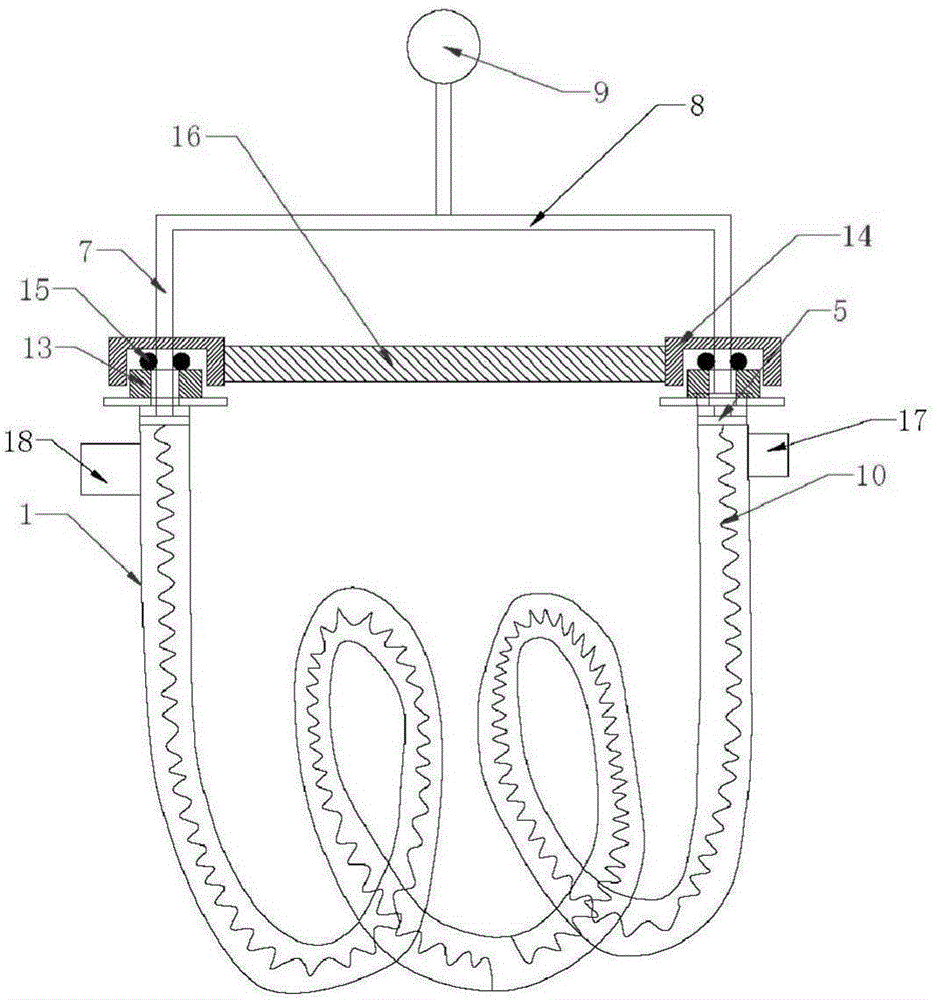

[0023] Such as figure 2 As shown, the electric heating tube with descaling device of the present invention includes a No. 1 glass tube and a coating 3 outside the No. 1 glass tube. An internal scraper 5 is arranged in the inner cavity of the No. 1 glass tube. The reciprocating driving part drives it to move in a straight line; said driving part is a pull rod 7 connected to the upper end of the internal scraper 5, and the pull rod 7 extends out of the No. 1 glass tube. The upper end of the pull rod 7 has an operating end 9, and the operating end 9 It can be operated manually or driven by a power device; the said pipe body 1 is a U-shaped pipe or a coiled pipe, and the first and last ends of the pipe body 1 are respectively fixed and installed through the installation ends, and a piece with a Outer threaded guide block 13, a nut 14 is installed outside each guide block 13, sealing ring 15 is all pressed between the upper end surface of each block guide block 13 and the inner en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com