A Friction Welding Control System

A control system and friction welding technology, applied in the field of friction welding, can solve the problems of high energy consumption, high contact resistance and high labor cost in electrolytic aluminum production, and achieve the effect of reducing labor cost, simplifying welding process and reducing the number of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Such as image 3 As shown, the friction welding control system includes a control unit 20 , a speed regulating unit 22 , a spindle motor 21 , a soft starter 24 and a power unit 23 . The speed regulation unit 22 is respectively connected with the control unit 20 and the spindle motor 21 , and the speed regulation unit 22 is used for receiving the speed regulation instruction sent by the control unit 20 and adjusting the rotation speed of the spindle motor according to the speed regulation instruction. The soft starter 24 is connected with the control unit 20 and the power unit 23 respectively, and the soft starter 24 is used for receiving the starting command sent by the control unit 20 and starting the power unit 23 according to the starting command. Wherein, the control unit 20 is a programmable logic controller (ProgrammableLogic Controller, hereinafter referred to as PLC), and the speed regulating unit 22 is a frequency converter.

[0030] The workflow of the fricti...

Embodiment 2

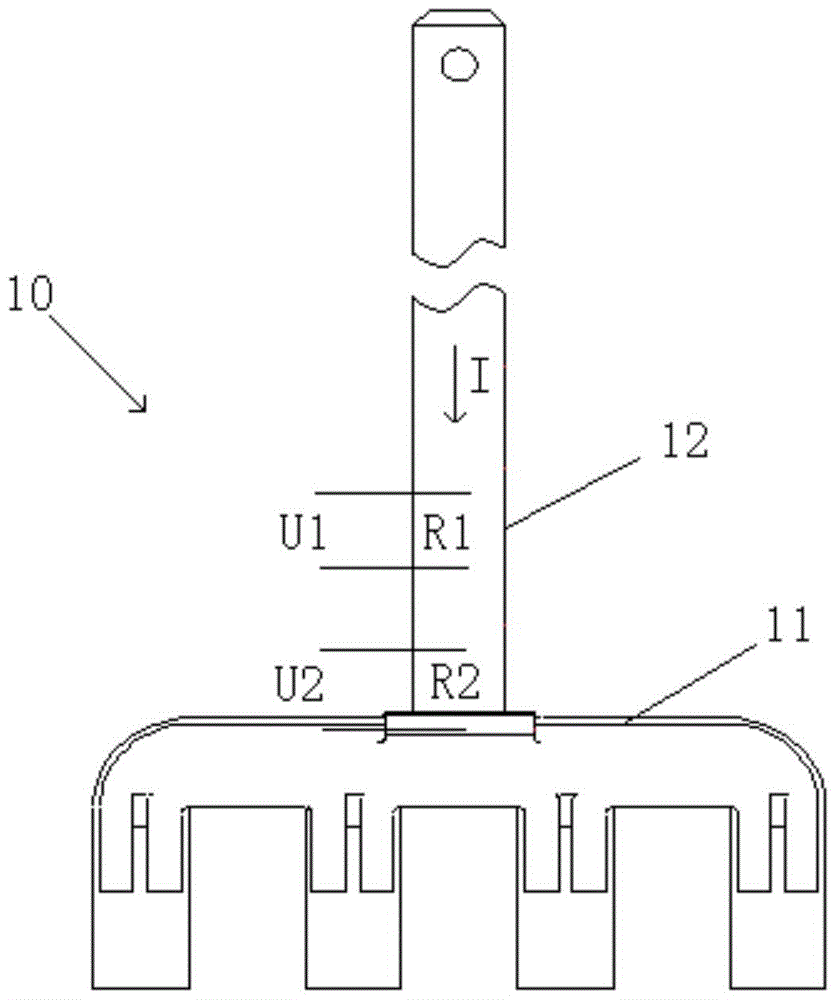

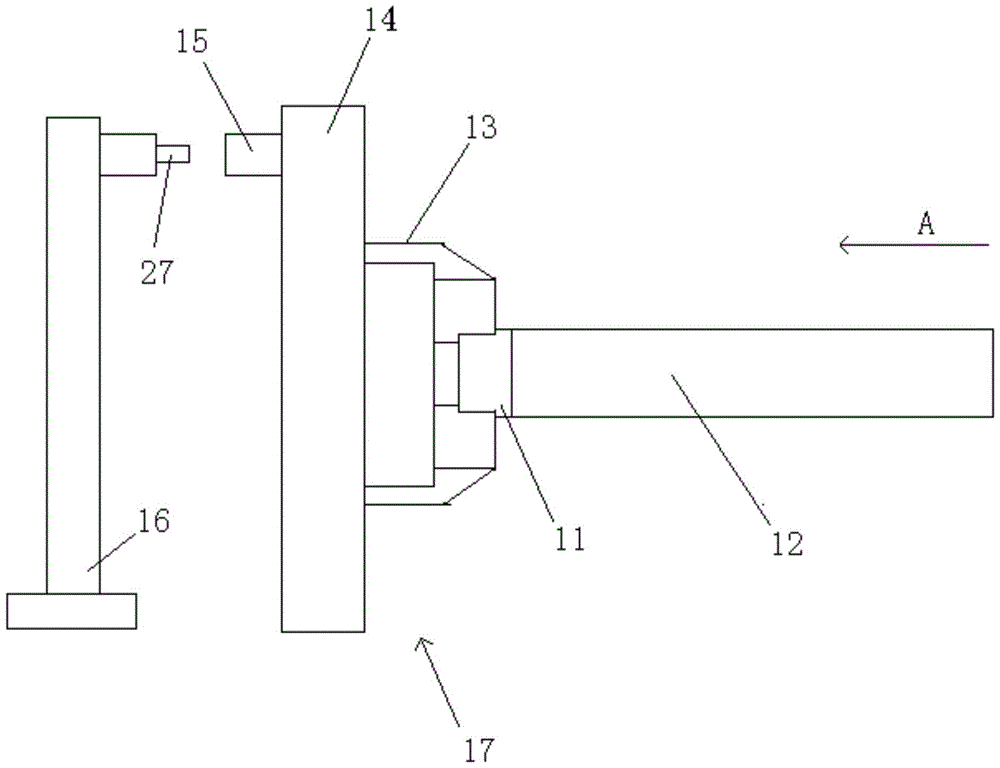

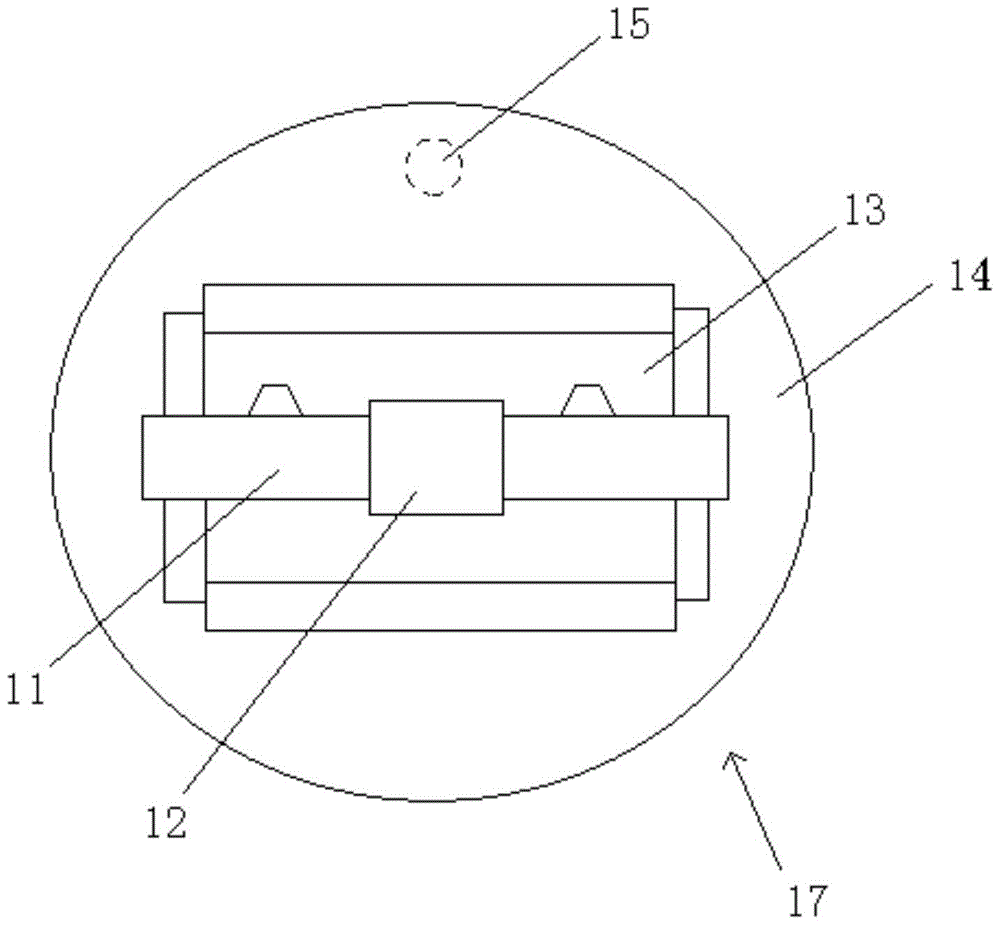

[0036] Such as Figure 5 As shown, the difference from the first embodiment is that the friction welding control system of the second embodiment also includes a positioning position unit 27, which is connected to the speed regulating unit 22, and the positioning position unit 27 is a proximity switch. Such as Figure 2a and Figure 2bAs shown, the steel claw clamp 17 includes a clamping port 13 and a disc 14, the clamping port 13 is fixedly connected to the disc 14, the clamping port 13 clamps the steel claw 11, and the positioning position unit 27 is installed on the base 16. During the friction welding process, the disc 14 and the clamping port 13 rotate synchronously under the drive of the spindle motor 21. A cylindrical metal bump 15 is arranged on the disc 14 at the direction of 12 o'clock. During the rotation of the disc 14, the cylindrical metal bump 15 Every time 15 passes the positioning position unit 27, that is, every time the steel jaw 11 rotates once, the positi...

Embodiment 3

[0042] Such as Figure 7 As shown, the friction welding control system also includes a steel claw information unit 25 , an aluminum guide rod information unit 26 and a speed feedback unit 28 .

[0043] The steel claw information unit 25 is connected with the speed reducer rear end of the control unit 20 and the main shaft motor 21 respectively, and the steel claw information unit 25 directly collects the position and speed information of the steel claw, and sends this information to the control unit 20, and the control unit 20 according to The position and speed information of the steel claw calculate the number of rotations of the steel claw and the specific angle of the current circle where the steel claw is located, so that the control unit 20 first detects the position and speed information of the steel claw before sending a positioning command to the speed regulating unit 22, To ensure that the steel claw is in the same position before each positioning command is sent, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com