Easy-to-assemble and disassemble heating furnace column embankment inner mold and its operation method

A heating furnace and inner mold technology, which is applied to ceramic forming cores, ceramic forming mandrels and other directions, can solve problems such as non-reusability, and achieve the effects of avoiding assembly inconvenience, saving construction materials, and improving construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the present invention, the present invention will be further explained and described below in conjunction with the accompanying drawings and specific embodiments.

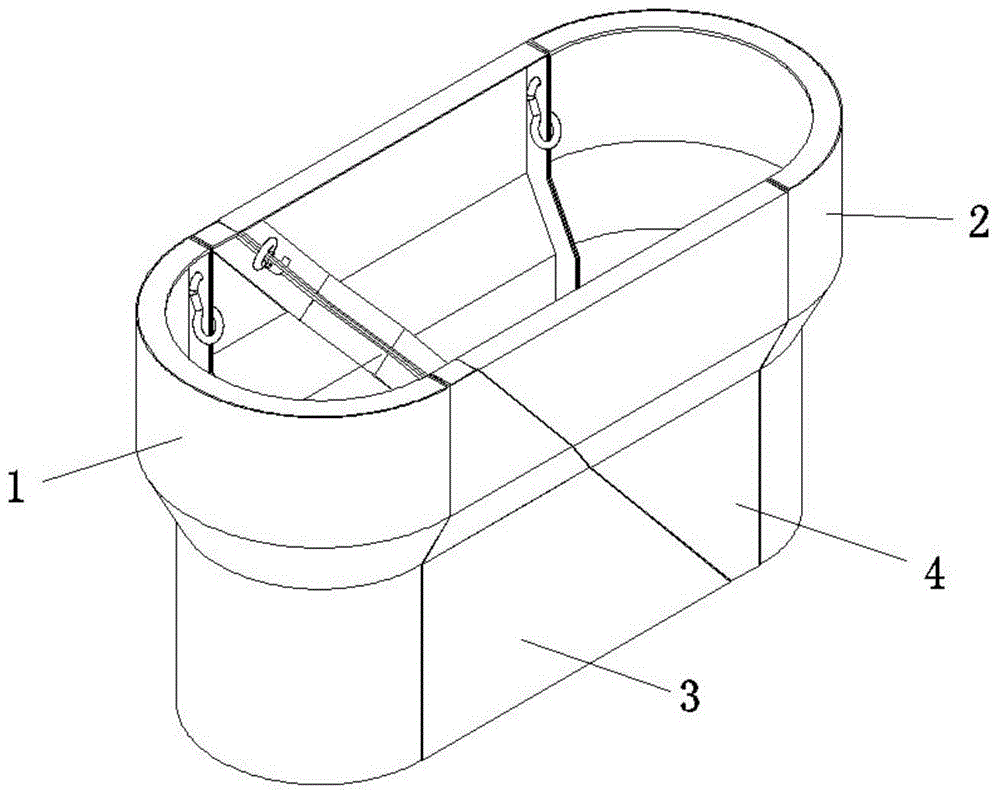

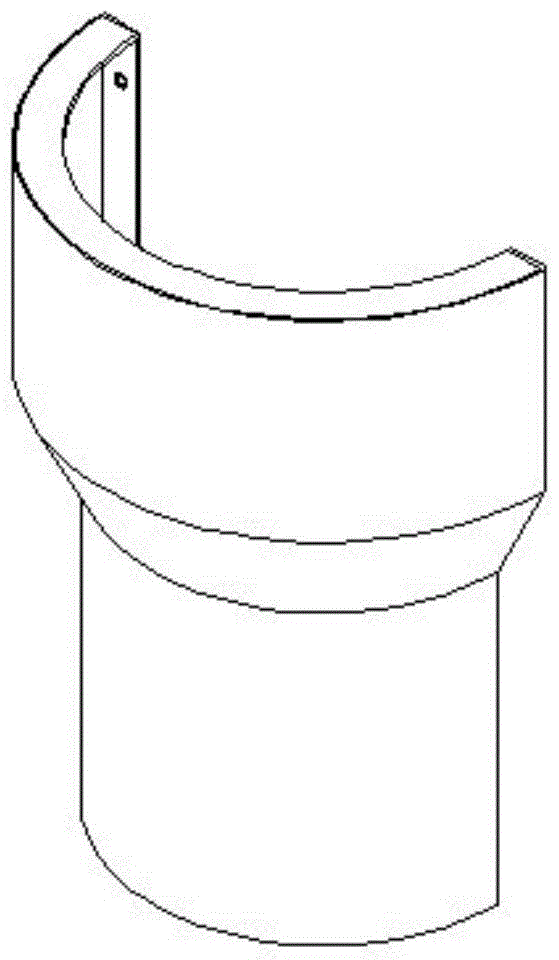

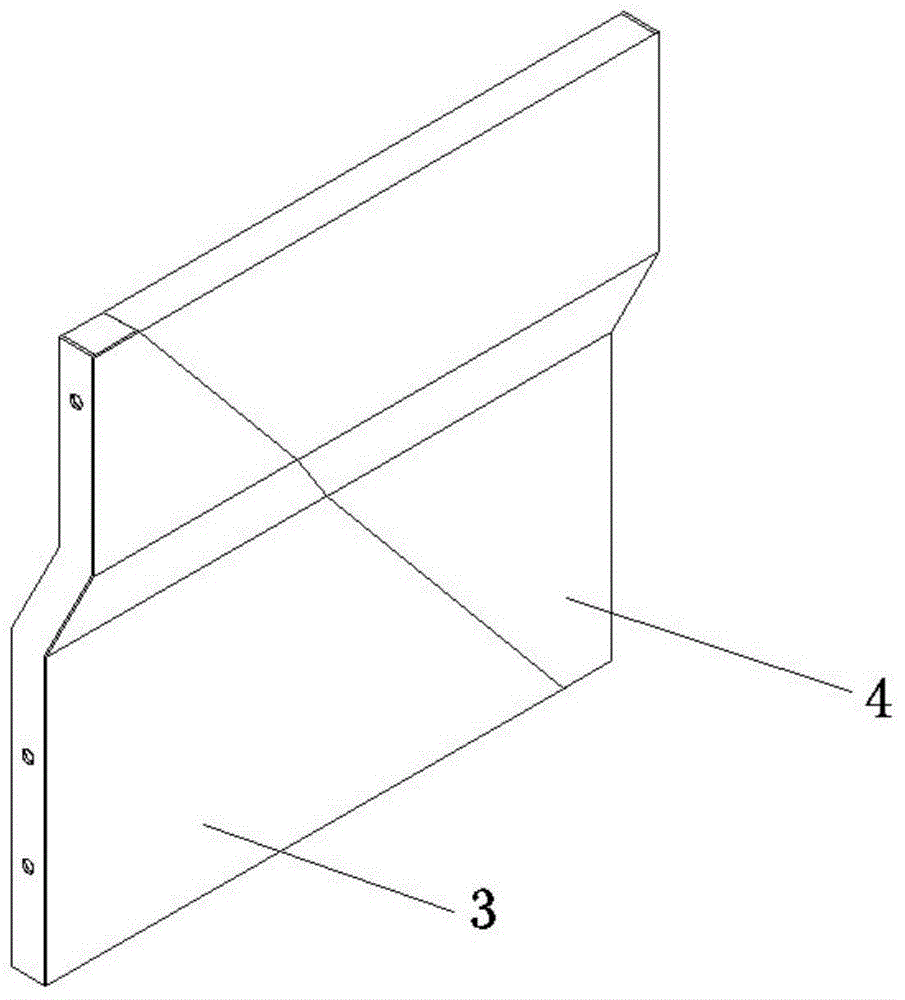

[0024] Such as figure 1 The shown one is easy to disassemble and assemble the inner mold of the column embankment of the heating furnace, including several U-shaped buckles, two sets of rectangular wedge-shaped assemblies as a whole, and the first component 1 and the second component 2 with the same structure, the first component 1 1. The height of the second member 2 is the same as that of the wedge assembly; the vertical edge of the first member 1 passes through a U-shaped buckle (such as Figure 4 shown) is spliced with one vertical edge of the wedge-shaped assembly, and the other vertical edge of the wedge-shaped assembly is spliced with the vertical edge of the second member 2 through a U-shaped buckle.

[0025] In this embodiment, the first member 1 and the second mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com