Double-valve dust discharge device for boiler smoke dust remover

A technology for boiler flue gas and dust collector, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of dust collector work failure, complex composition, production and life loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

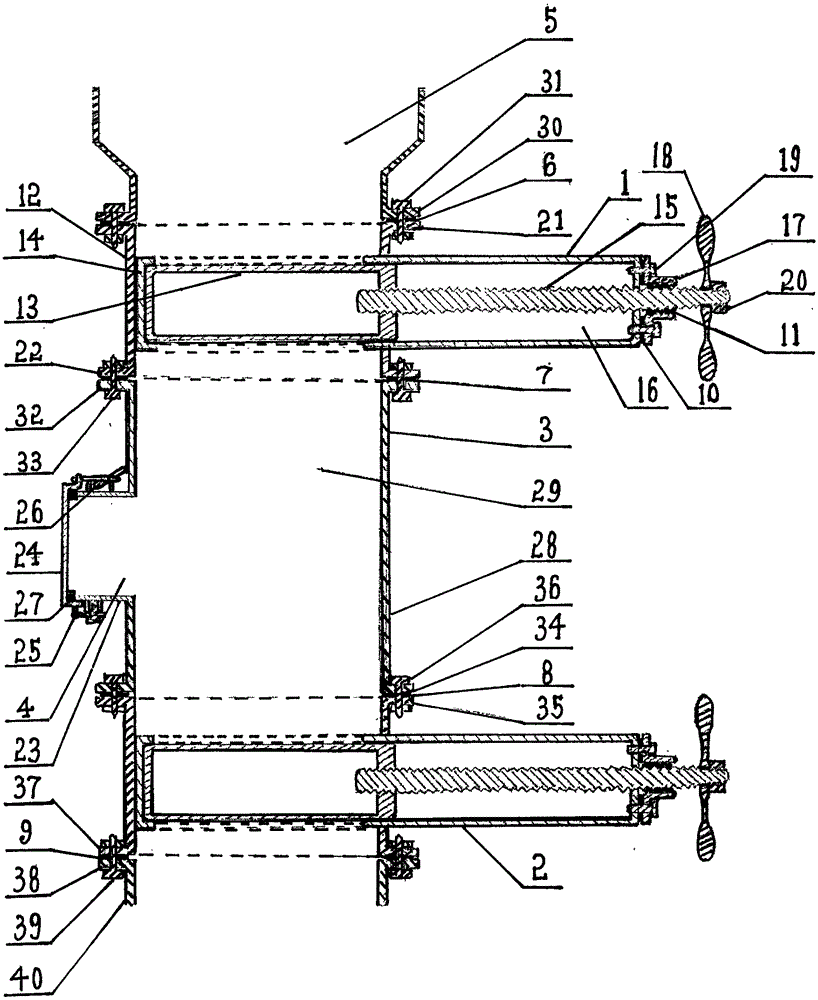

[0008] Such as figure 1 As shown, a double-valve ash release device for boiler flue gas dust collector of the present invention consists of an upper valve 1, a lower valve 2, a transitional ash bin 3, an inspection window 4 and seals 6, 7, 8, 9, 10, 11, Composition. And the upper valve 1 and the lower valve 2 are two fully open valves with the same structure. The valve is composed of a valve body 12, a plate 13, a plate groove 14, a screw rod 15, a plate warehouse 16, and a screw rod. The connecting bolt 19 of the fixed seat 17, the manual wheel 18, the screw rod fixed seat 17, the fixed nut 20 of the manual wheel 18, the flanges 21, 22 and the seals 6, 7 are composed; the maintenance window 4 of the present embodiment consists of a window 23, window cover 24, hinge 25, locking member 26 and sealing member 27 are formed;

[0009] The valve 1 on the ash release device of this embodiment is connected to the ash bin 5 of the dust collector through flanges 21, 30 and bolts 31, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com