A high-precision installation method of a bull's-eye substrate and a sealing cylinder base

An installation method and high-precision technology, applied in infrastructure engineering, construction, etc., can solve the problems of reducing bearing capacity, affecting positioning accuracy, and difficulty in ensuring the relative position and elevation accuracy of anchor bolts, so as to avoid swinging and shifting , The effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

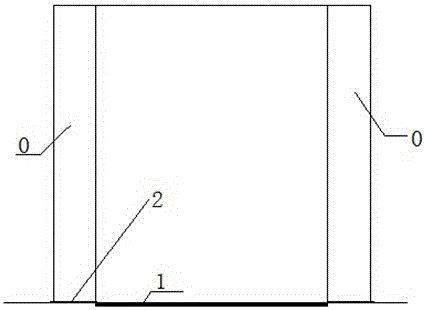

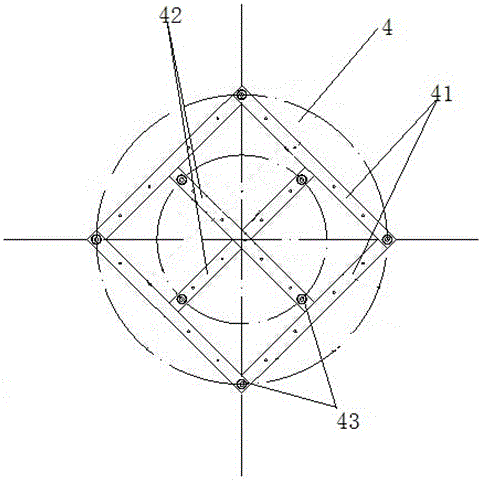

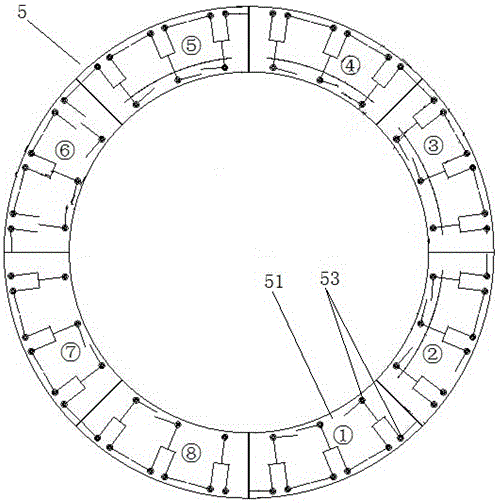

[0042]A high-precision installation method for a bullseye base plate 1 and a sealing cylinder base 2, the base plate 1 is provided with eight anchor bolt holes 110, four grouting holes 120 and eight exhaust holes 13, and the four grouting holes 120 are evenly Distributed on the same circumference, eight exhaust holes 13 are also evenly distributed on the same circumference, and the circumference where the grouting holes 120 are located is located inside the circumference where the inner side of the exhaust holes 13 is located; the base 2 is provided with seventy-two Anchor hole 21, eight grouting holes 120 and sixteen vent holes 13, wherein eight grouting holes 120 are all distributed on the same circle, and sixteen vent holes 13 are also evenly distributed on the same circle, the grouting The circle where the hole 120 is located is located inside the circle where the exhaust hole 13 is located (as figure 2 shown);

[0043] The installation method includes the following step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com