Magnetic circuit decoupled and permanent magnet biased active-passive hybrid axial-radial magnetic bearing

A magnetic levitation bearing and permanent magnetic bias technology, applied in the field of magnetic bearings, can solve the problems of large volume, internal and external structure repulsion type radial passive magnetic bearings, small radial stiffness, large power consumption, etc., to achieve reduced magnetic resistance and compact structure , reducing the effect of torque coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

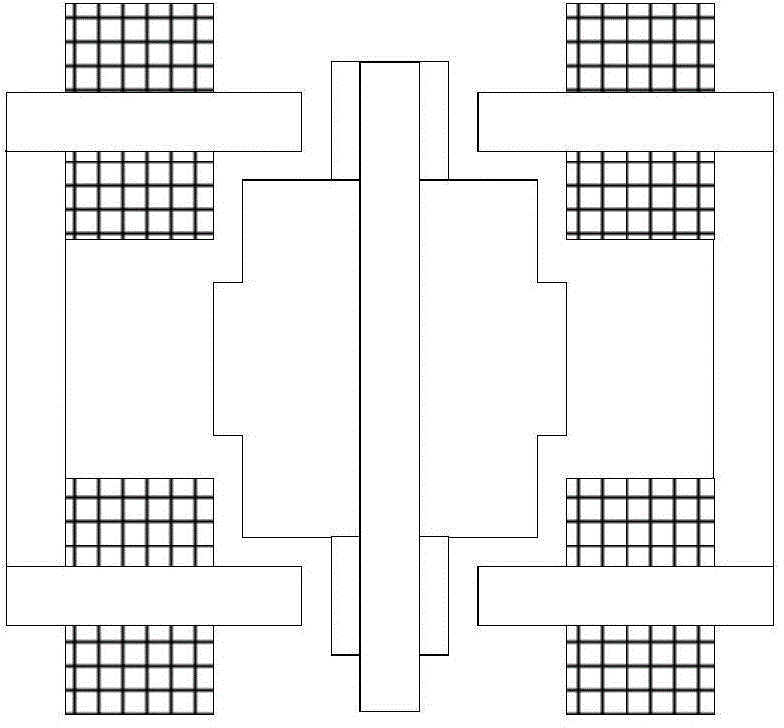

[0043] Specific implementation mode one: combine figure 1 with 2Describe this embodiment, the magnetic circuit decoupling permanent magnet bias active and passive hybrid axial radial magnetic suspension bearing described in this embodiment, the magnetic suspension bearing includes internal and external structure repulsion type radial passive magnetic bearing and permanent magnetic bearing of the same polarity The magnetic bias axial active magnetic bearing; the same polarity permanent magnet bias axial active magnetic bearing includes a stator and the rotor, and the repulsive radial passive magnetic bearing includes a permanent magnet 3 on the stator side and a permanent magnet 4 on the rotor side. The inner and outer structures The repulsion type radial passive magnetic bearing is placed in the cavity between the rotor and the stator of the same polarity permanent magnet bias axial active magnetic bearing, and the rotor and the stator of the same polarity permanent magnet bia...

specific Embodiment approach 2

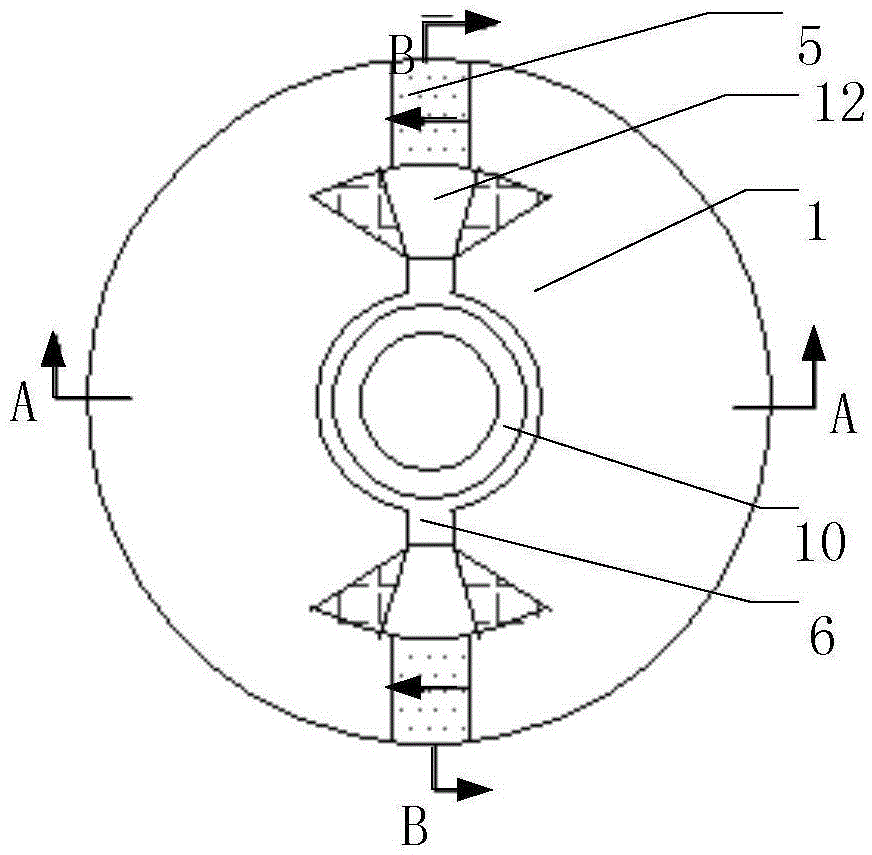

[0045] Specific implementation mode two: combination image 3 , Figure 4 , Figure 5 , Image 6 with Figure 18 Describe this embodiment. This embodiment is a further definition of the magnetic circuit decoupling permanent magnet bias active and passive hybrid axial radial magnetic suspension bearing described in the first embodiment. The same polarity permanent magnet bias shaft The active magnetic bearing includes a stator and a rotor, and there is an axial air gap between the stator and the rotor; the stator includes armature teeth 1, a stator core and two flat stator permanent magnets 5, and the rotor includes a rotor core 6 and a shaft 11, The rotor core 6 is fixed on the shaft 11; the stator core includes a left half stator core 2-1 and a right half stator core 2-2;

[0046] Two flat stator permanent magnets 5 are arranged between the left half stator core 2-1 and the right half stator core 2-2, and form a cylindrical structure; the rotor core 6 is located in the cy...

specific Embodiment approach 3

[0058] Specific implementation mode three: combination Figure 7 This embodiment is described. This embodiment is a further limitation of the magnetic circuit decoupling permanent magnet bias active and passive hybrid axial radial magnetic suspension bearing described in the second specific embodiment.

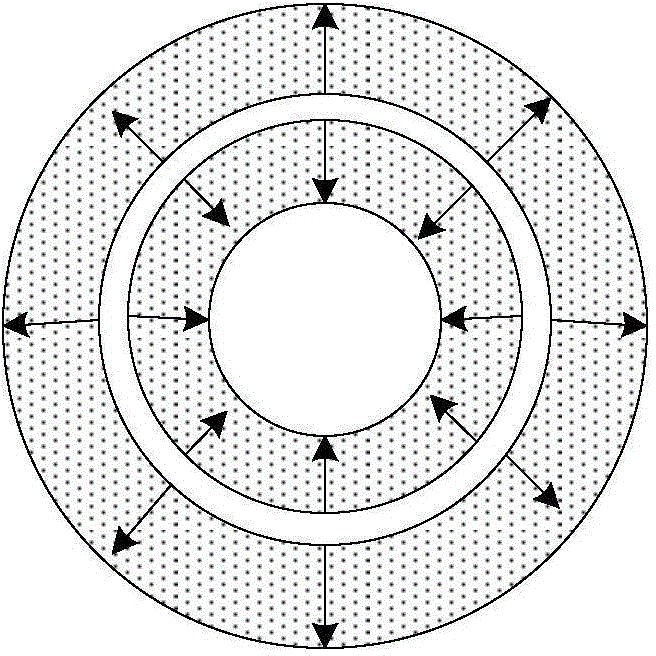

[0059] The rotor side permanent magnet 4 is composed of two rotor permanent magnet rings, and the two rotor permanent magnet rings are arranged and fixed in sequence along the axial direction, and are fixed on the outer circular surface of the rotor iron core 6; The direction of magnetization is opposite;

[0060] The stator side permanent magnet 3 is composed of two stator permanent magnet rings, and the two stator permanent magnets are arranged and fixed in sequence along the axial direction as a whole, and are fixed on the inner circular surface of the cylindrical structure; the magnetization of the two stator permanent magnet rings in the opposite direction.

[0061] In ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap