An anisotropic direct shear test system for geosynthetics and its implementation method

A geosynthetic material, anisotropic technology, applied in the direction of using a stable shear force to test the strength of the material, can solve the problem that the mechanical properties of the interface between the geosynthetic material and the filling can not be truly reflected, and achieves the solution of randomness and solution. The effect of security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

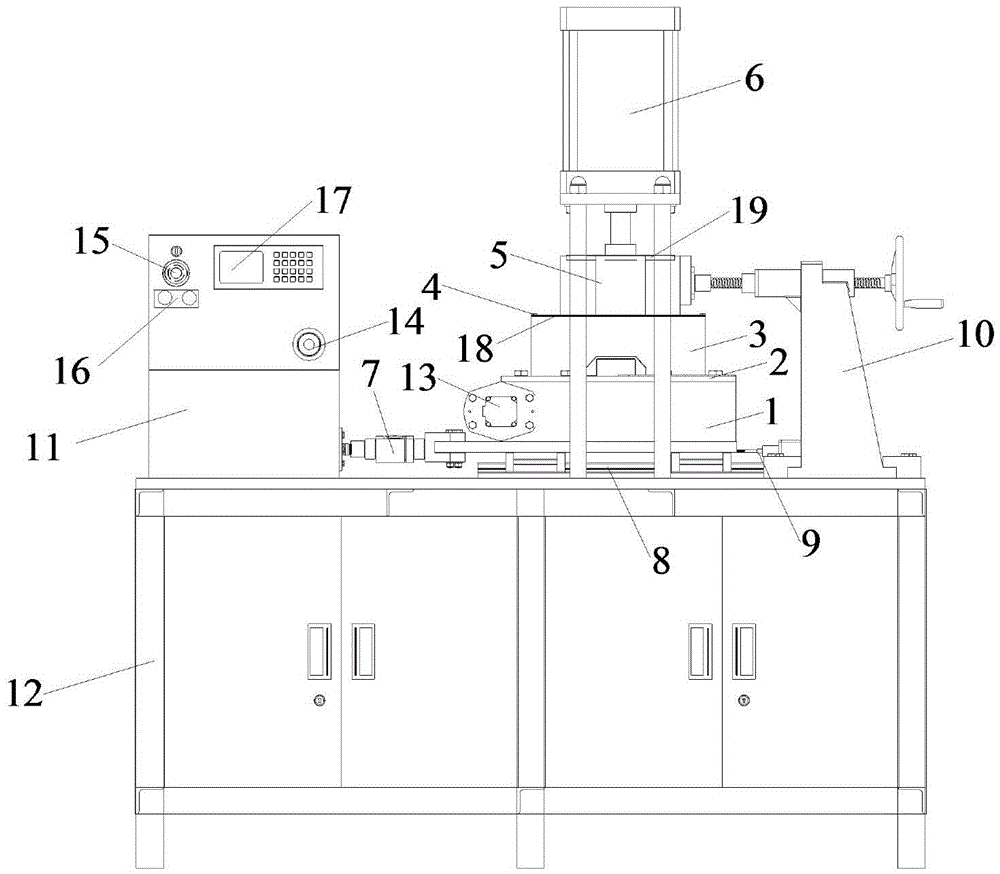

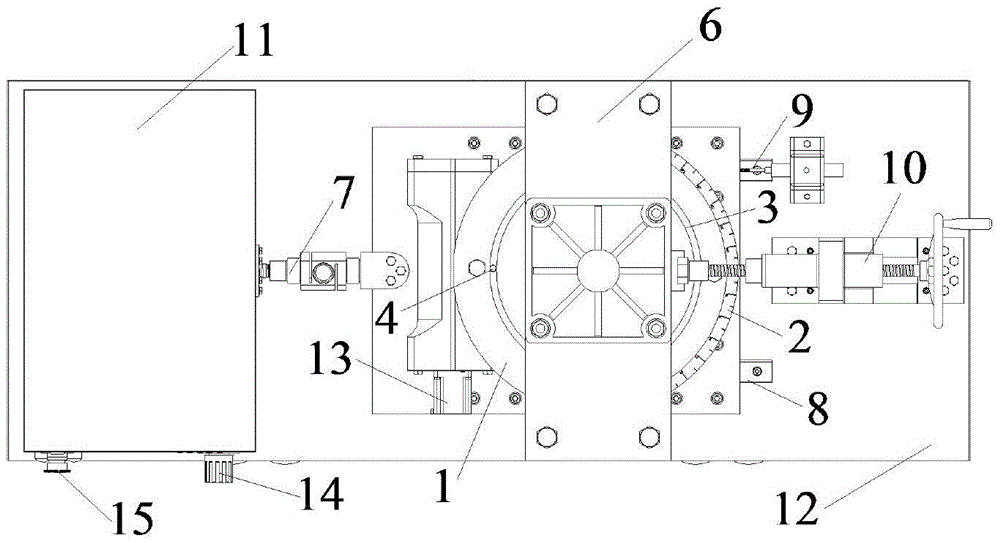

[0038] see figure 1 as well as figure 2 , an anisotropic direct shear test system for geosynthetics, comprising a slewing bearing 1, a dial 2, a lower shear box 3, a fixture 4, an upper shear box 5, a vertical loading device 6, a horizontal loading device 7, and guide rails 8. Displacement sensor 9, fixed support 10, cabinet 11, test bench 12, slewing bearing control device 13, vertical loading control device 14, horizontal loading control device 15, running indicator light 16, intelligent display control acquisition device 17, Geosynthetic material sample 18, bearing plate 19.

[0039] The lower shear box 3 is a semi-closed hollow cylinder with an inner diameter of 300mm, a thickness of 5mm and a height of 150mm.

[0040] The upper shear box 5 is a regular octagonal inscribed cylinder with an inner diameter of 200 mm, a thickness of 3 mm at the weakest point, and a height of 100 mm, and the difference between the octagonal outer diameter of the upper shear box 5 and the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com