Electrostatic atomizer

An electrostatic spray and mist technology, applied in electrostatic spray devices, spray discharge devices, spray devices, etc., can solve problems such as liquid leakage of electrostatic spray device 100

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

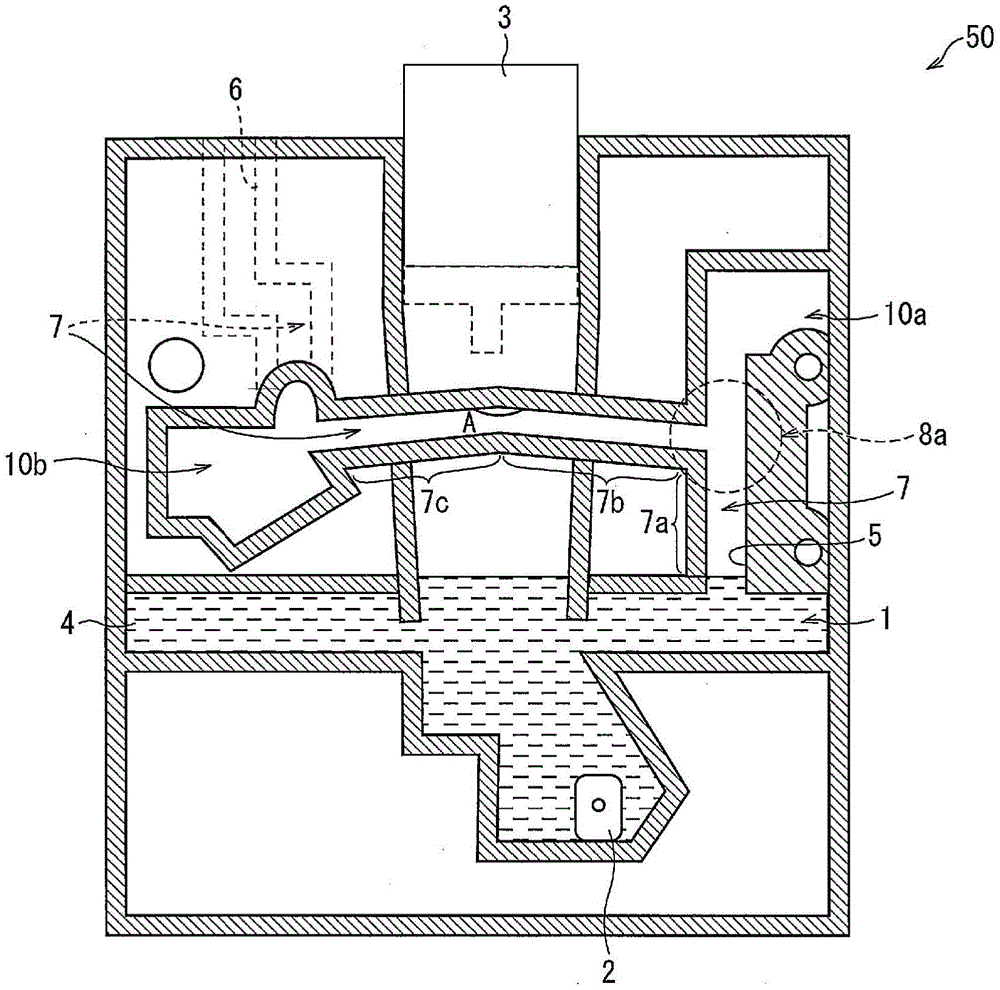

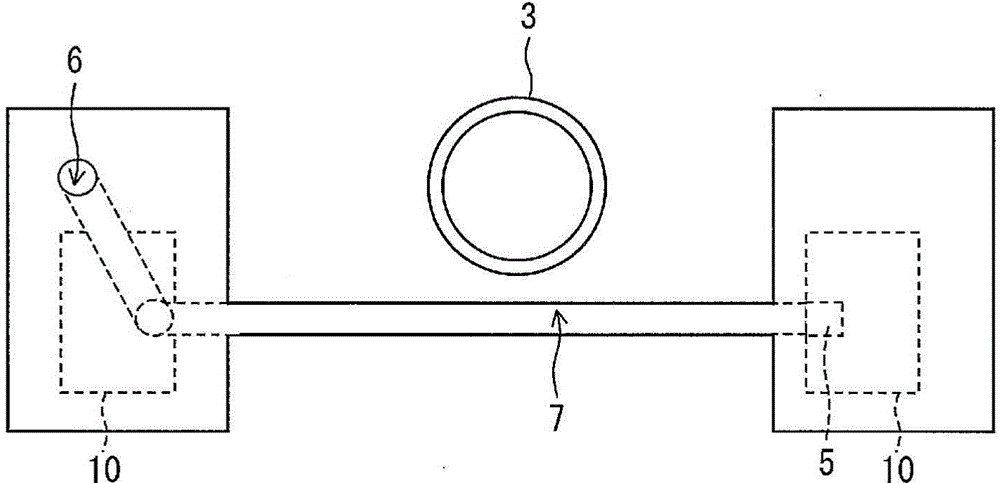

[0080] in turn figure 1 The electrostatic spray device 50 was laid down in four directions, front, back, left, and right, and whether there was any liquid leakage was confirmed, and then it was restored to the original state, thereby confirming whether there was any liquid leakage. It should be noted that, in the electrostatic spray device 50, there are two places with a capacity of 200mm 3 In the liquid holding space 10, the angle A of the air path 7 is 170°, and in a part of the air path 7, an inclination of 5° is provided to the left and right, respectively.

[0081] The setting conditions of the electrostatic spray device 50 are as follows.

[0082] Capacity of chamber 1: 200mm 3

[0083] The diameter of the liquid level maintenance hole 5 (four corners): 1mm

[0084] The diameter of the air hole 6 (round): 1mm

[0085] Length of air path 7 (shaft length): 26mm

[0086] The linear distance between the liquid level maintenance hole 5 and the air hole 6: 11mm

[0087...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com