Rapid clamping fixture with adjustable pressing force

A technology of clamping clamp and pressing force, applied in the field of eccentric fast clamping platen, which can solve the problems of inapplicability and inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

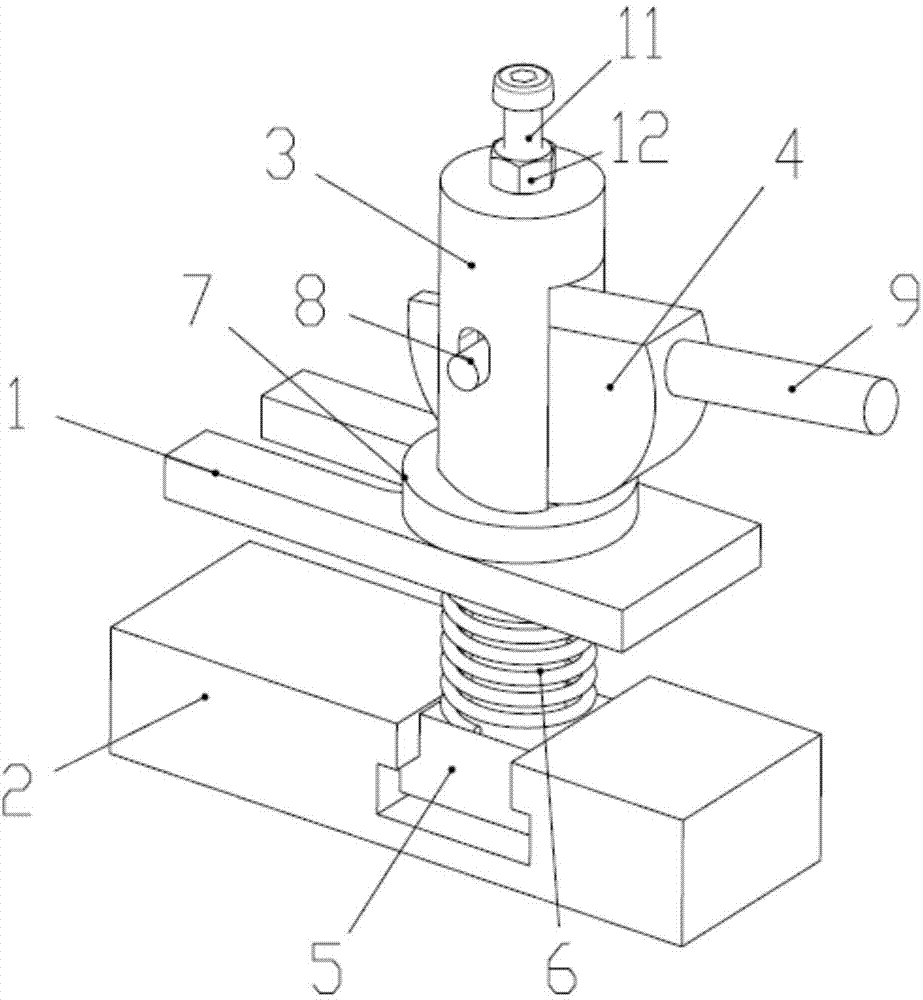

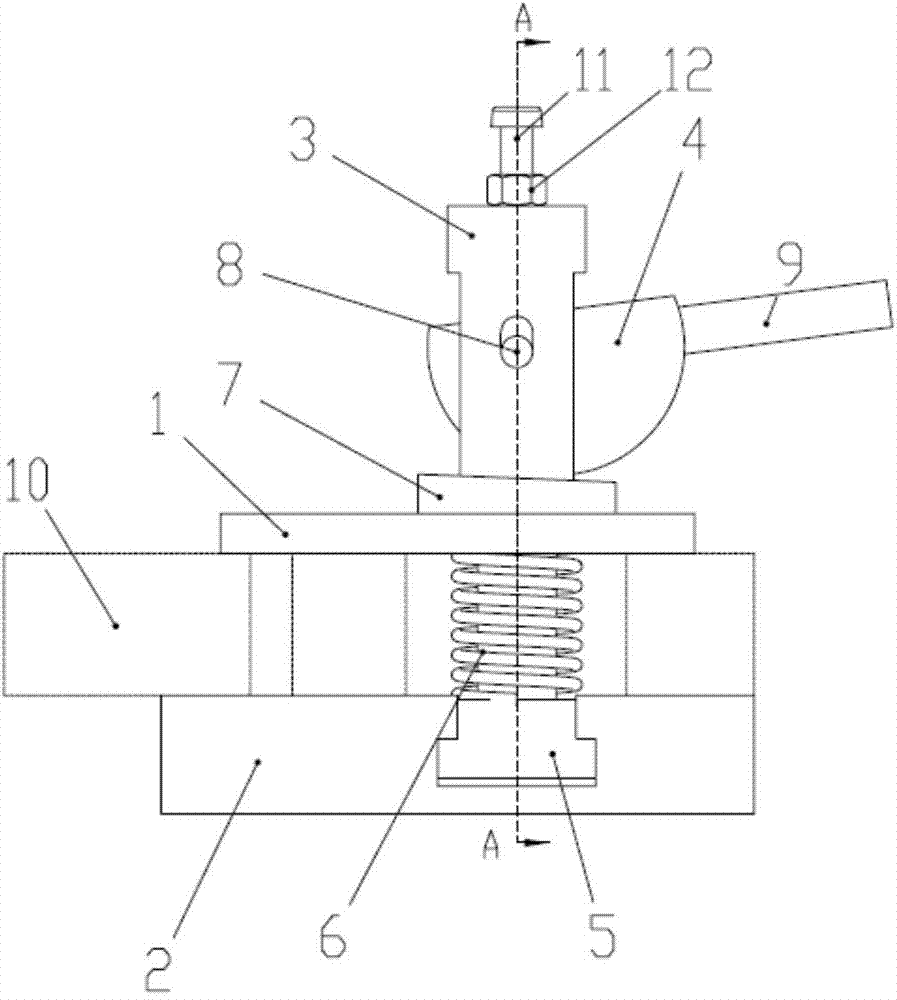

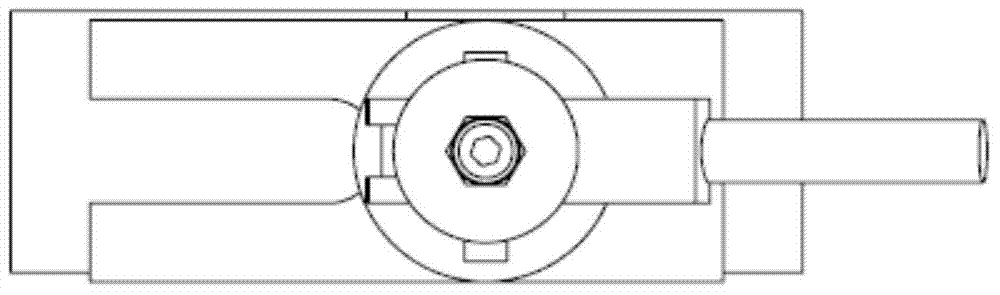

[0015] like Figure 1 to Figure 4 As shown, a fast clamping fixture with adjustable pressing force includes a pressing plate 1, a connecting rod 3, a T-shaped nut 5, an eccentric semicircular block 4, an inclined washer 7, a return spring 6, a pin shaft 8, a rotating handle 9, Adjust bolt 11, lock nut 12.

[0016] The middle part of the connecting rod 3 is connected with the pressure plate 1, and the lower end of the connecting rod 3 is fixedly connected with the workbench 2 through the T-nut 5. There is a long waist hole in the upper part of the connecting rod 3, and the eccentric connection is movable through the pin shaft 8 in the long waist hole. Semicircle block 4, connecting rod 3 upper end is provided with adjusting bolt 11 and lock nut 12, and adjusting bolt 11 bottom surface is connected with bearing pin 8, and the oblique washer 7 that is sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com