A flipping mechanism for a side-drawing mold

A technology of overturning mechanism and mould, which is applied in the direction of manufacturing tools, equipment for transporting casting molds, metal processing equipment, etc. It can solve problems such as overturning, mold collapse, and loud noise, so as to reduce the use of power components, reduce complexity and The effect of enlarged wiring and operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

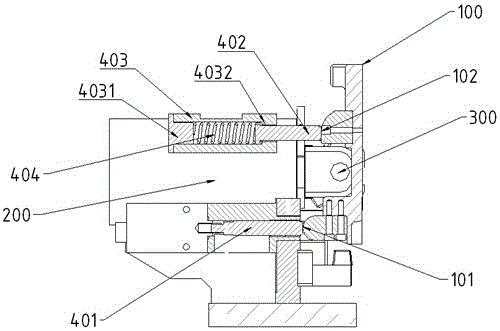

[0023] Embodiment one: see figure 1 , as shown in the legend therein, a flipping mechanism for a side-drawing mold, the side-drawing mold 100 is a movable mold and at least two are arranged, the fixed mold is a bottom mold, and the side-drawing mold 100 has a horizontal opening and closing direction, The main oil cylinder 200 is arranged on the outer surface of the side drawing mold 100, and the driving direction of the main oil cylinder 200 is the same as that of the side drawing mold 100. The outer surface, the outer surface of the side drawing die 100 is provided with a first apex 101 located on the lower side of the rotating shaft 300 and a second apex 102 located on the upper side of the rotating shaft 300, the first apex 101, the rotating shaft 300 and the second apex The part 102 constitutes a lever mechanism, and the turning mechanism includes a turning oil cylinder 401, a push rod 402, a guide sleeve 403 and a pre-tightening return spring 404. The turning 401 is arran...

Embodiment 2

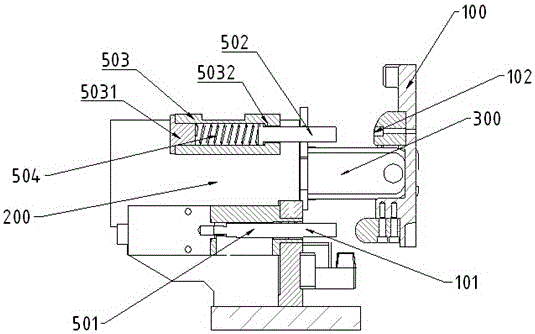

[0035] Embodiment two: see figure 2 , as shown in the legend therein, a flipping mechanism for a side-drawing mold, the side-drawing mold 100 is a movable mold and at least two are arranged, the fixed mold is a bottom mold, and the side-drawing mold 100 has a horizontal opening and closing direction, The main oil cylinder 200 is arranged on the outer surface of the side drawing mold 100, and the driving direction of the main oil cylinder 200 is the same as that of the side drawing mold 100. The outer surface, the outer surface of the side drawing die 100 is provided with a first apex 101 located on the lower side of the rotating shaft 300 and a second apex 102 located on the upper side of the rotating shaft 300, the first apex 101, the rotating shaft 300 and the second apex The part 102 constitutes a lever mechanism, and the turning mechanism includes a first ejector rod 501, a second ejector rod 502, a guide sleeve 503, and a pre-tightening return spring 504. The first eject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com