Tight nozzle cover

A technology of leaking nozzle and nozzle head, applied in the field of containers, can solve the problems of increasing consumption of plastic raw materials, increasing product cost, easily polluted beverages, etc., and achieving the effects of reducing the use of plastic raw materials, saving product costs, and reducing wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below with reference to the accompanying drawings.

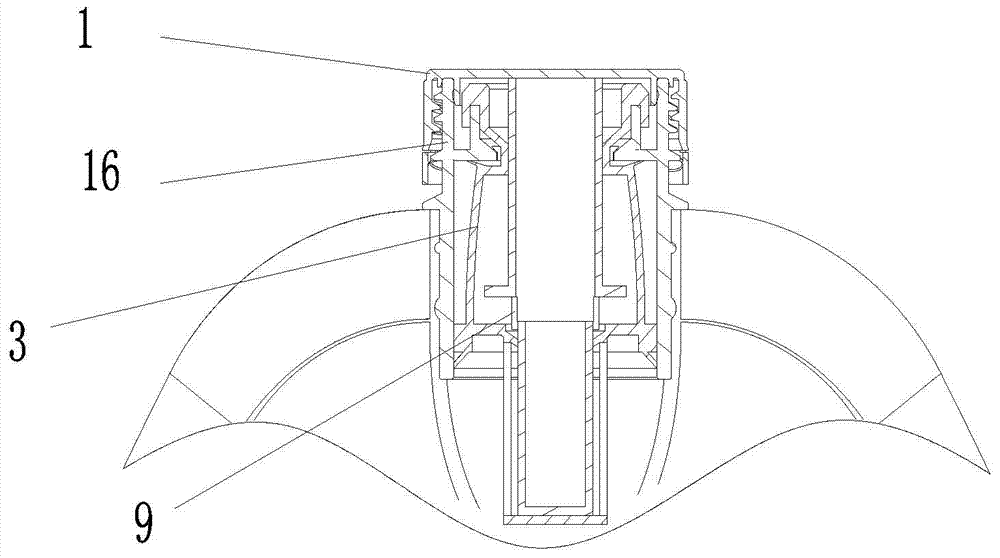

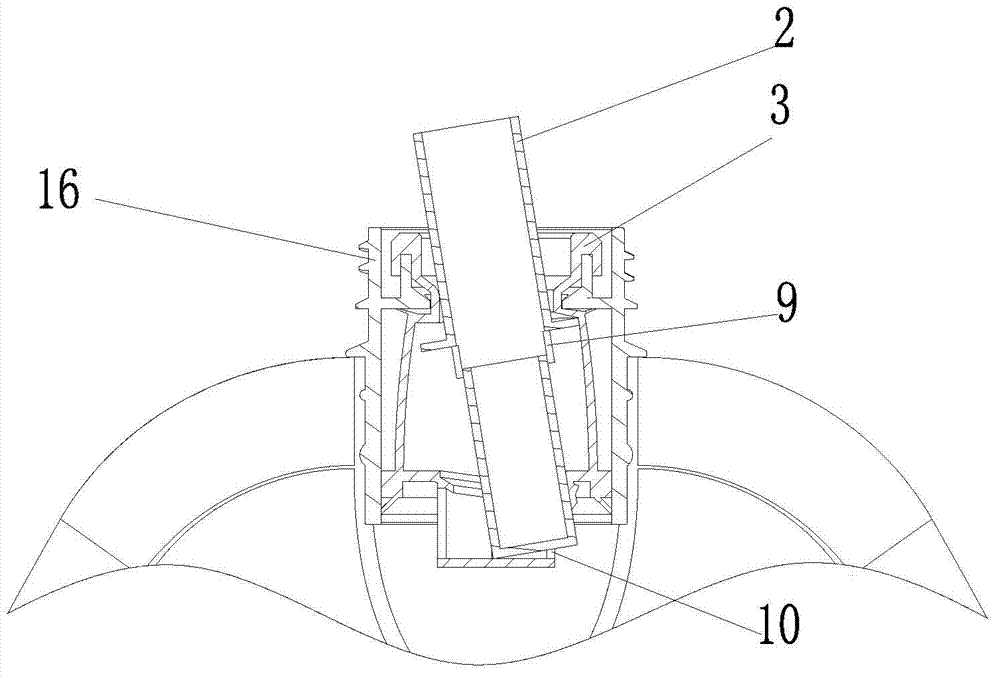

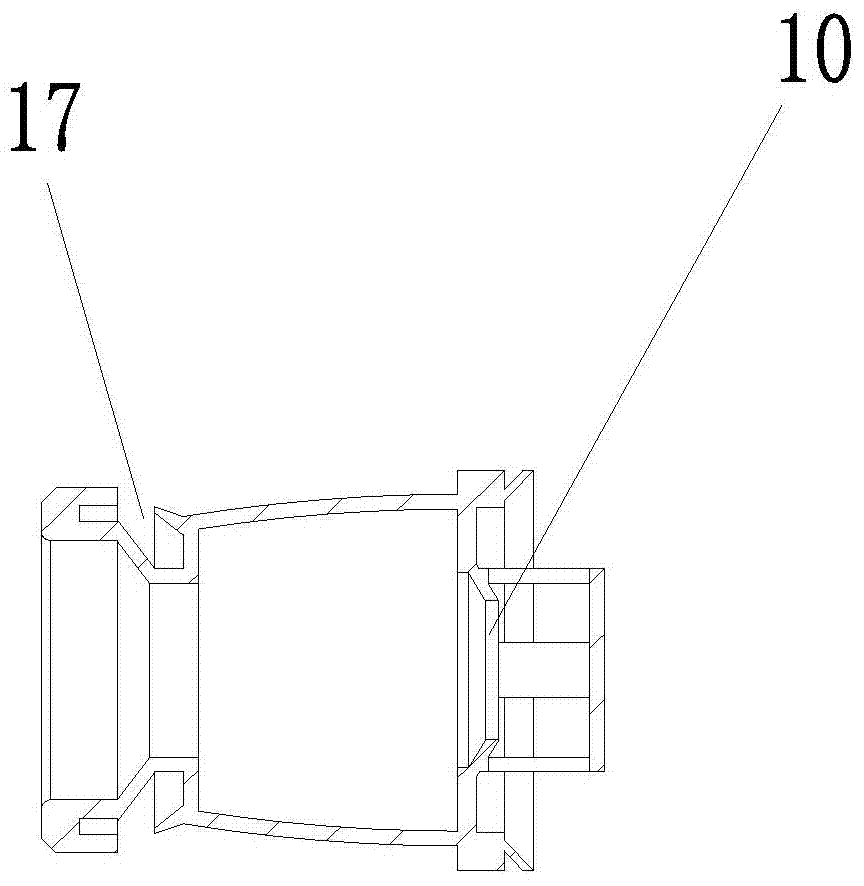

[0014] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a non-spout cover includes a container cover 1, a lever body 2, a silicone tray 3 and a nozzle head 16 for screwing on the container mouth. The middle part of the lever body 2 is provided with an annular clamping position 5, and the lever The body 2 has a trigger lever 6 and a water outlet rod 7, the water outlet rod 7 is accommodated in the cavity of the silicone tray 3, the outer upper edge of the water outlet rod 7 is provided with at least one first water outlet hole 9, the container cover 1 and the nozzle head 16 rotate The inner wall of the cavity of the silicone tray 3 is provided with an annular rib 11 for the annular clamping position 5 to lean against, and the outer upper edge of the silicone tray 3 is provided with an outer annular clamping position 17, and the bottom of the cavity of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com