Lime bin with material blocking preventive function

A white ash and anti-blocking technology, applied in the field of white ash silos, can solve the problems of increasing the labor intensity of workers, affecting the normal loading and unloading of white ash, polluting the surrounding environment, etc. It is beneficial to health, avoid environmental pollution or labor, and is less difficult to transform Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

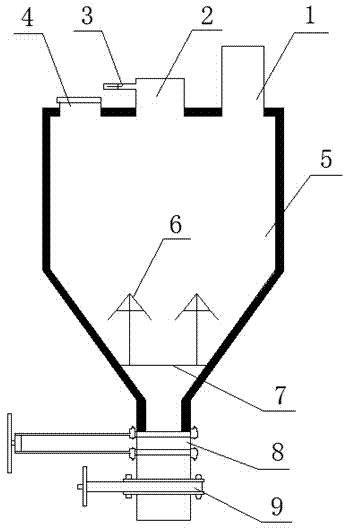

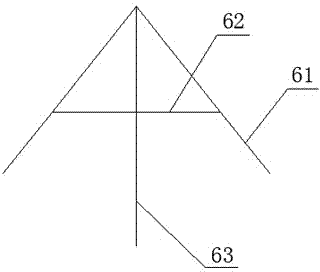

[0014] see Figure 1-2 , an anti-blocking lime silo, comprising a pulse powder collector 1, an ash inlet box 2, a lime conveying pipeline 3, a pressure relief valve 4, a silo body 5, an anti-blocking material device 6, a gate valve 8 and an impeller Feeder 9; the pulse powder collector 1, ash inlet box 2 and pressure relief valve 4 are all located on the silo body 5, the pulse powder collector 1 plays a role of dust removal through back blowing, and the pressure relief valve 4 is used to prevent The pressure in the silo is too high, the lime conveying pipe 3 is set on the ash inlet box 2, and the ash inlet box 2 is connected to the lime tank truck through the lime conveying pipe 3, and the lime in the lime tank car is sent into the dust inlet box 2 through the lime conveying pipe 3 , and then enter the silo body 5; the lower part of the silo body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com