Fiber unfolding winding device

A technology of winding device and guide roller, which is used in transportation and packaging, transportation of filamentous materials, thin material processing, etc. Easy to change and other problems, to achieve the effect of stabilizing the winding thread, reducing the variation of the thread and not easy to bifurcate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

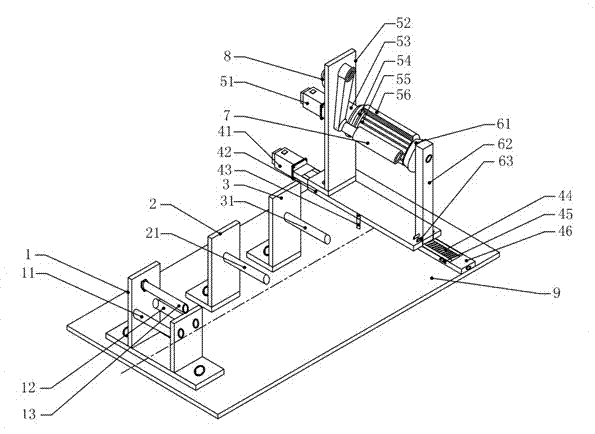

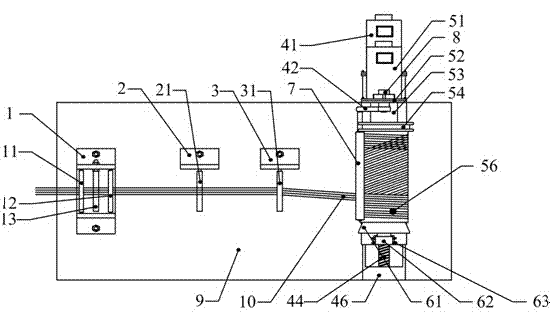

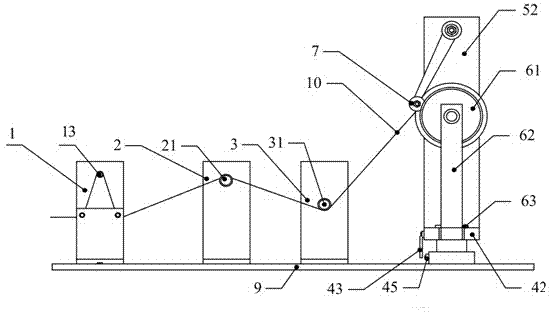

[0019] From figure 1 , figure 2 , image 3 As can be seen in , a fiber spreading and winding device includes a base 9, a tension detection sensor mechanism, a guide roller set, a translation mechanism, a winding mechanism, and the like.

[0020] The tension detection and sensing mechanism of the present invention includes a front guide roller 11 , a rear guide roller 12 and a cantilevered upper guide roller 13 installed on the tension detection support 1 . Tension sensors are installed on the cantilever type upper guide roller 13 . It is a tension sensing component that deforms under the action of fiber tension, and the signal processing part at the rear end of the tension sensor processes the deformation into a measurable tension value. The tension detection support 1 is located at the front part of the whole winding device, and is fixed on the base 9 by screws. Both ends of the front guide roller 11 and the rear guide roller 12 are respectively fixed on the tension dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com