Method and device for liquid flow deposition of film on inner wall of silicon micro-channel by utilizing improved differential pressure method

A technology of silicon microchannel and differential pressure method, used in microstructure devices, manufacturing microstructure devices, decorative arts, etc., can solve problems such as inability to deposit, and achieve the effect of improving overall performance and improving film deposition unevenness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical characteristics of the present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

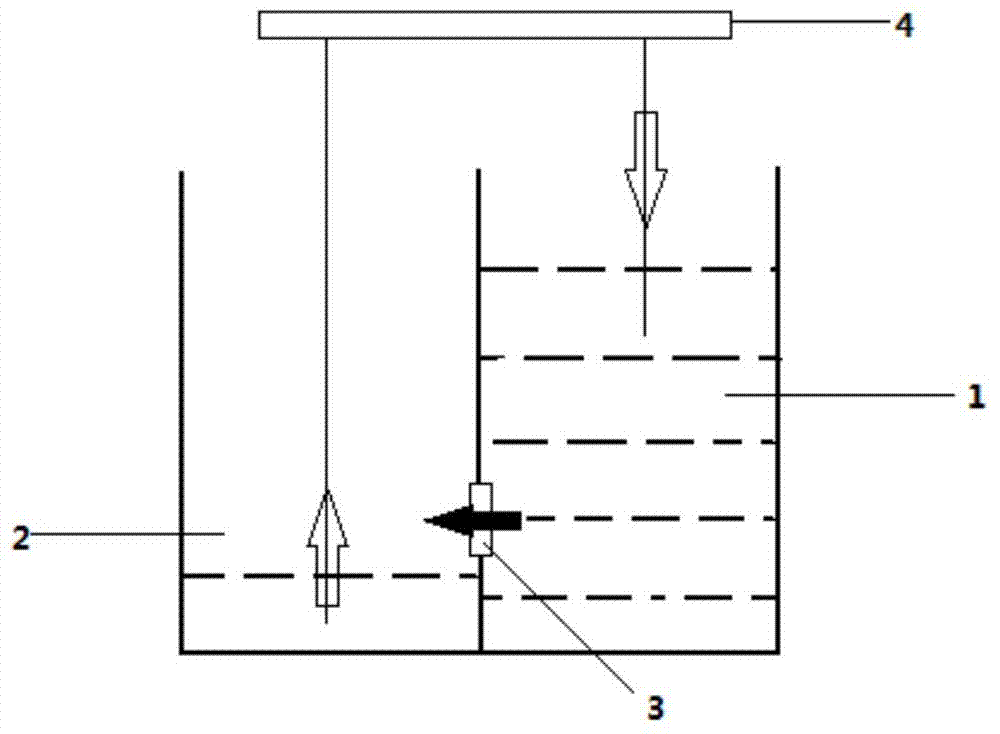

[0023] Such as figure 1 Shown, a kind of improved differential pressure method liquid flow deposits thin film device on the inner wall of silicon microchannel, comprises container; Described container is divided into two cavities by dividing plate cavity: the first cavity 1 and the second cavity Two cavities 2; the dividing plate between the first cavity 1 and the second cavity 2 is provided with a draw-in groove 3 communicating with the two cavities; a silicon microchannel is placed on the draw-in groove 3; in the first A circulating pump 4 is arranged between the cavity 1 and the second cavity 2, wherein the water inlet of the circulating pump 4 is set at the bottom of the second cavity 2, and the water outlet is set above the first cavity 1; The first cavity 1 is filled with a plating solution for flow depos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap