Self-shearing pin for heat-insulation building formworks

A technology of building thermal insulation and self-breaking, which is applied in the direction of construction, building structure, and on-site preparation of building components, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

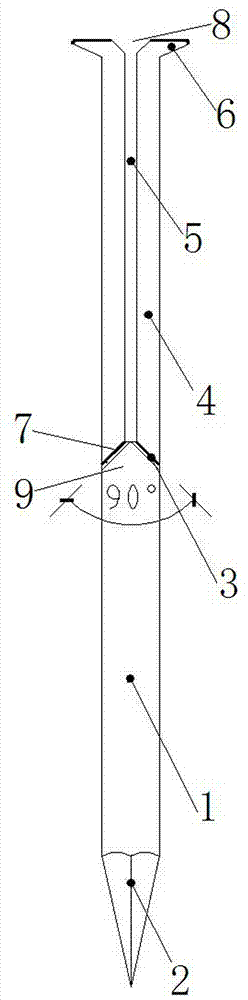

[0015] Refer to attached Figure 1~3 The building insulation mold self-breaking nail includes an iron nail 1, a modified ABS nail shank and an adhesive layer 3; the rear end of the iron nail 1 and the front end of the modified ABS nail shank are bonded with the adhesive layer 3, and the iron nail 1 A conical nail head 2 is arranged on the upper part, and a conical connecting head 9 is arranged on the rear end of the iron nail 1 .

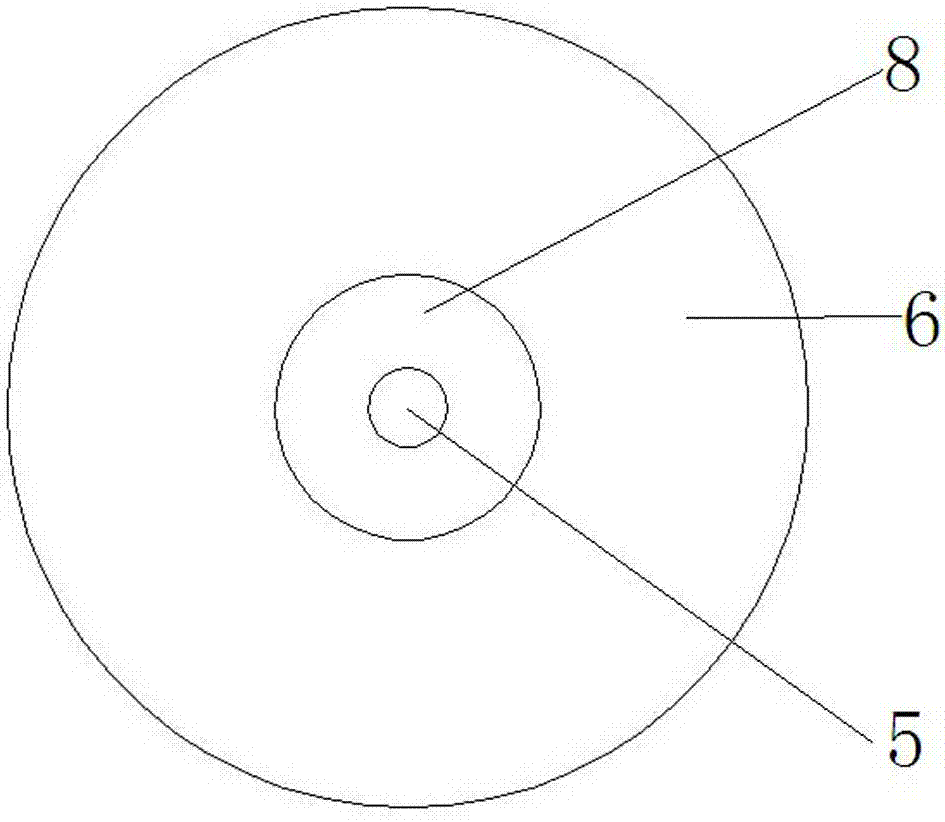

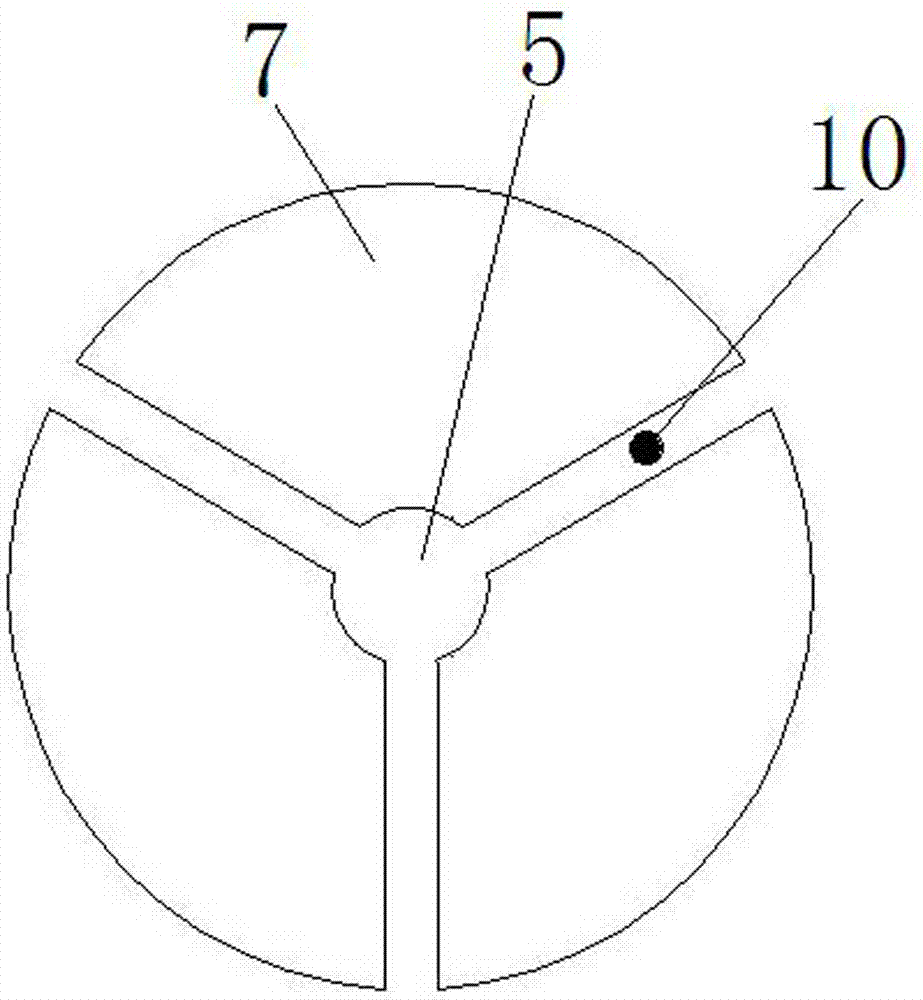

[0016] The rear end of the modified ABS nail rod is provided with a nail cap 6 , the middle part is provided with a nail rod 4 , the front end is provided with a conical connecting fork 7 , and the conical connecting fork 7 is provided with a water guide groove 10 .

[0017] The center of the nail rod 4 is provided with a central water guide hole 5, and the central water guide hole 5 communicates with the water guide groove 10 provided by the conical connecting fork 7.

[0018] There are at least two water guiding grooves 10 for the conical connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com